The conductive polymer coating market is rapidly evolving as industries seek new solutions to meet the growing demand for advanced materials that combine electrical conductivity, flexibility, and environmental sustainability. These coatings are gaining prominence due to their wide range of applications in electronics, automotive, aerospace, energy, and healthcare. However, the market is influenced by several dynamics—technological advancements, evolving consumer needs, economic factors, and regulatory pressures—that are shaping its growth trajectory. This article delves into the key market dynamics influencing the conductive polymer coating sector.

1. Technological Advancements in Conductive Polymers

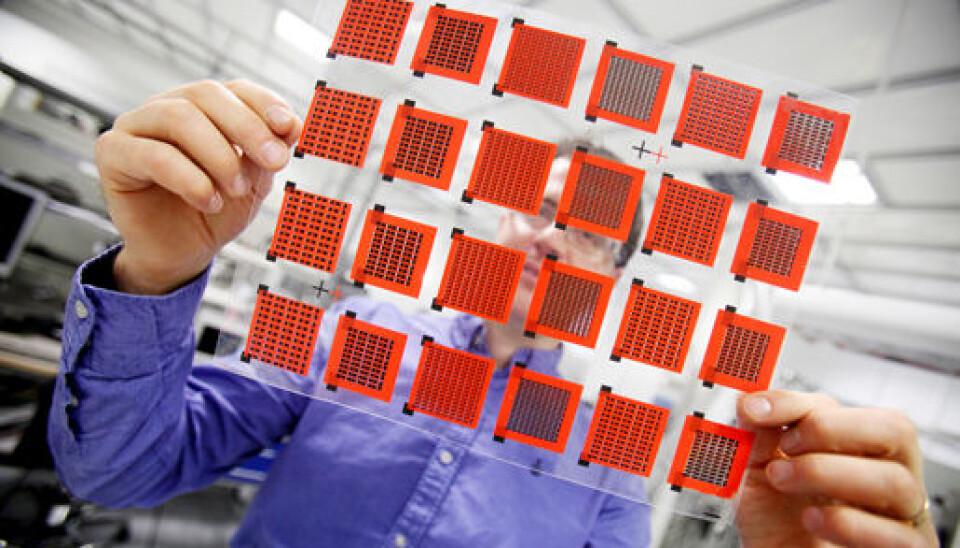

One of the most influential factors driving the growth of the conductive polymer coating market is the continuous technological innovation in conductive polymers. Researchers are increasingly exploring new materials, including carbon nanotubes (CNTs), graphene, and silver nanoparticles, to improve the electrical conductivity and mechanical properties of polymer coatings. These materials enhance the performance of coatings, enabling them to meet the specific requirements of high-tech applications such as flexible electronics, wearable devices, and electric vehicles (EVs).

The advancement of nanomaterials and the development of new polymer synthesis techniques are crucial in improving the overall efficiency of conductive polymer coatings. These innovations are enhancing the electrical performance, durability, and environmental stability of the coatings, making them suitable for applications in more demanding environments.

2. Growing Demand for Flexible Electronics

The demand for flexible electronics is a key driver of the conductive polymer coating market. The rise of consumer electronics, such as smartphones, wearables, and bendable displays, has created a strong demand for coatings that not only conduct electricity but also offer flexibility and durability. Flexible polymer coatings can be applied to curved or stretchable substrates, making them essential for the development of wearable tech and other flexible electronic devices.

In particular, conductive polymer coatings are used in flexible displays, printed circuit boards (PCBs), and other electronic components. As the market for flexible and foldable electronics continues to grow, so too will the demand for high-performance conductive polymer coatings that can maintain electrical conductivity without compromising on flexibility or strength.

3. Expansion of Electric Vehicle (EV) Market

The rapid adoption of electric vehicles (EVs) is another dynamic influencing the conductive polymer coating market. EVs rely on various electrical systems, including batteries, charging stations, motors, and power management systems. Conductive polymer coatings are essential for ensuring the durability and functionality of these electrical systems, as they help protect sensitive components from moisture, corrosion, and electromagnetic interference (EMI).

The increasing demand for electric vehicles and the drive for energy-efficient and sustainable solutions are pushing automakers and suppliers to explore new materials and technologies, including conductive polymer coatings. As EVs become more mainstream, the need for reliable and efficient coatings to protect electrical components and improve the overall performance of the vehicles will continue to grow.

4. Environmental Sustainability and Regulatory Pressures

Sustainability has become a central theme across many industries, and the conductive polymer coating market is no exception. The increasing demand for eco-friendly and non-toxic coatings is driving the development of water-based and bio-based conductive polymer coatings. These coatings provide an alternative to traditional solvent-based coatings, which contain volatile organic compounds (VOCs) that are harmful to both the environment and human health.

Regulatory pressures, particularly in regions with strict environmental laws, such as the European Union and North America, are encouraging manufacturers to adopt greener coating solutions. As a result, there is a growing focus on developing sustainable conductive polymer coatings that comply with these environmental standards, thus opening new growth opportunities in eco-conscious industries.

5. Challenges of High Material Costs

Despite their numerous benefits, one of the significant challenges in the conductive polymer coating market is the high cost of raw materials, especially advanced conductive materials like carbon nanotubes and graphene. These materials, while improving the performance of the coatings, add to the overall cost of production. High material costs can make conductive polymer coatings less attractive to cost-sensitive industries, particularly in price-competitive markets like consumer electronics and automotive manufacturing.

Moreover, the high cost of production can limit the adoption of these coatings in some applications, particularly in emerging markets where cost efficiency is a primary concern. However, as research into new, cost-effective materials continues, the overall cost of conductive polymer coatings is expected to decrease over time, broadening their adoption in diverse industries.

6. Market Fragmentation and Competitive Landscape

The conductive polymer coating market is highly fragmented, with numerous players involved in the development, production, and distribution of coatings. These players include large chemical companies, material science firms, and specialized coating manufacturers. The fragmented nature of the market creates a highly competitive environment, where companies need to differentiate themselves through innovative products, superior performance, and customer service.

As the market matures, consolidation may occur, leading to the formation of stronger market leaders with broader technological capabilities and market reach. Additionally, companies may seek partnerships or collaborations with academic institutions or research organizations to drive the development of next-generation conductive polymer coatings.

7. Rising Importance of Electromagnetic Interference (EMI) Shielding

As electronic devices become increasingly complex and interconnected, the need for effective electromagnetic interference (EMI) shielding is growing. Conductive polymer coatings are widely used to protect electronic components from EMI, which can interfere with the proper functioning of devices. This demand for EMI protection is particularly strong in sectors like aerospace, telecommunications, and automotive, where the performance and safety of electronic systems are critical.

Conductive polymer coatings offer an efficient solution to EMI shielding, providing an alternative to traditional metal-based shielding methods. With the increasing reliance on electronic systems across industries, the demand for coatings that offer both conductivity and EMI protection is expected to continue to rise.

Conclusion

The conductive polymer coating market is undergoing significant growth driven by technological advancements, increasing demand for flexible electronics and electric vehicles, environmental sustainability concerns, and the rising need for EMI shielding. However, challenges such as high material costs, market fragmentation, and regulatory pressures must be addressed to fully unlock the potential of this market. As innovation continues to drive improvements in material performance, cost-effectiveness, and sustainability, the conductive polymer coating market is expected to witness steady growth in the coming years, with vast opportunities for application across a wide range of industries.