-

8 Posts

-

3 Photos

-

0 Videos

-

Male

-

Followed by 0 people

Recent Updates

-

Oxygen-Free Innovation: Why Airless is Taking Over

1. A New Paradigm in Packaging

Escaping Oxygen’s Grip: The Science Behind Airless Systems

Oxygen—so essential for life, yet so detrimental to product longevity. In the realm of packaging, it's a silent saboteur. It oxidizes delicate formulations, degrades active ingredients, and turns premium products into pale imitations of themselves. The solution? Airless technology.

Airless packaging is engineered to outsmart oxygen. Through piston-based dispensers and sealed chambers, these systems evacuate the need for internal air. Each pump delivers a precisely measured dose, untouched by external contaminants. It's an elegant symphony of engineering—a quiet, vacuum-powered triumph of modern science.

for more inform : https://market.us/report/airless-packaging-market/

From Traditional to Transformational: The Packaging Shift

For decades, packaging was functional but flawed. Tubes leaked. Pumps sputtered. Jars invited bacteria. Now, form and function coalesce in the airless era. This transformation isn't cosmetic—it’s structural.

Where old systems relied on gravity and exposed nozzles, airless packaging uses negative pressure and hermetic seals. The result? Extended shelf life, consistent dispensing, and nearly 100% product evacuation. No shaking. No waste. No compromise. Just innovation, sealed tight.

2. Industries Embracing the Airless Revolution

Beauty and Skincare’s Clean Demand

In the beauty world, perception is everything—but preservation is essential. Skincare brands are under pressure to deliver clean, preservative-light formulas that stay potent until the last pump. Enter the airless dispenser: a guardian of integrity, an icon of minimalism.

High-performance ingredients like hyaluronic acid, vitamin C, and retinoids demand an oxygen-free environment. With airless packaging, these actives maintain their efficacy, untouched by spoilage or degradation. And with sleek, modern aesthetics, brands communicate purity and prestige in a single, silent click.

Pharmaceuticals, Nutraceuticals, and Purity Protocols

Beyond vanity lies necessity. In the pharmaceutical and nutraceutical sectors, sterility is non-negotiable. Contamination isn't an inconvenience—it’s a liability.

Airless containers, with their tamper-evident structures and dose control mechanisms, are ideal for delivering creams, gels, and semi-solids without compromise. Whether it’s a dermatological treatment or a wellness elixir, the technology ensures that every dispense is sterile, precise, and protected.

3. Sustainability Meets Sophistication

Minimal Waste, Maximum Yield

In a world grappling with excess, airless packaging offers something radical: efficiency. These systems are designed for near-total evacuation. Every drop is dispensed, leaving no residual waste clinging to the walls of a bottle.

That means consumers get more for their money—and less ends up in landfills. The reduction in product waste pairs with an increasing use of recyclable and reusable components. It’s sustainability without sacrifice. Precision, wrapped in conscience.

for more inform : https://market.us/report/airless-packaging-market/

Eco-Luxury and the Rise of Smart Materials

As luxury converges with environmental consciousness, packaging must evolve. Enter bio-resins, glass hybrids, and refillable cartridges—materials designed to impress without excess.

Airless packaging now walks the fine line between indulgence and responsibility. No longer just utilitarian, it becomes an expression of ethical elegance. A modern emblem of brands that care about both people and planet.

Conclusion

Airless packaging is not a passing trend—it’s a tectonic shift. It redefines how products are preserved, how brands are perceived, and how sustainability is pursued. Oxygen, once an unavoidable enemy of longevity, is now outwitted by innovation. In this brave, sealed new world, airless is more than a dispenser—it's the future, pressurized and precises

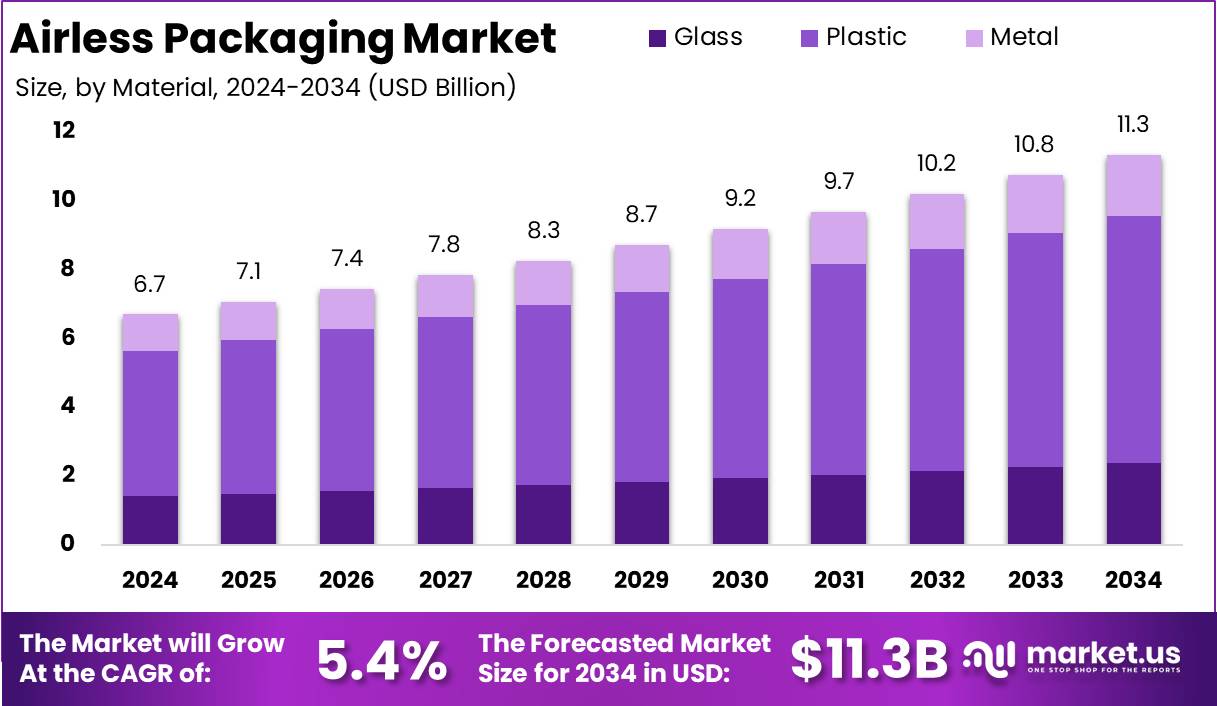

Oxygen-Free Innovation: Why Airless is Taking Over 1. A New Paradigm in Packaging Escaping Oxygen’s Grip: The Science Behind Airless Systems Oxygen—so essential for life, yet so detrimental to product longevity. In the realm of packaging, it's a silent saboteur. It oxidizes delicate formulations, degrades active ingredients, and turns premium products into pale imitations of themselves. The solution? Airless technology. Airless packaging is engineered to outsmart oxygen. Through piston-based dispensers and sealed chambers, these systems evacuate the need for internal air. Each pump delivers a precisely measured dose, untouched by external contaminants. It's an elegant symphony of engineering—a quiet, vacuum-powered triumph of modern science. for more inform : https://market.us/report/airless-packaging-market/ From Traditional to Transformational: The Packaging Shift For decades, packaging was functional but flawed. Tubes leaked. Pumps sputtered. Jars invited bacteria. Now, form and function coalesce in the airless era. This transformation isn't cosmetic—it’s structural. Where old systems relied on gravity and exposed nozzles, airless packaging uses negative pressure and hermetic seals. The result? Extended shelf life, consistent dispensing, and nearly 100% product evacuation. No shaking. No waste. No compromise. Just innovation, sealed tight. 2. Industries Embracing the Airless Revolution Beauty and Skincare’s Clean Demand In the beauty world, perception is everything—but preservation is essential. Skincare brands are under pressure to deliver clean, preservative-light formulas that stay potent until the last pump. Enter the airless dispenser: a guardian of integrity, an icon of minimalism. High-performance ingredients like hyaluronic acid, vitamin C, and retinoids demand an oxygen-free environment. With airless packaging, these actives maintain their efficacy, untouched by spoilage or degradation. And with sleek, modern aesthetics, brands communicate purity and prestige in a single, silent click. Pharmaceuticals, Nutraceuticals, and Purity Protocols Beyond vanity lies necessity. In the pharmaceutical and nutraceutical sectors, sterility is non-negotiable. Contamination isn't an inconvenience—it’s a liability. Airless containers, with their tamper-evident structures and dose control mechanisms, are ideal for delivering creams, gels, and semi-solids without compromise. Whether it’s a dermatological treatment or a wellness elixir, the technology ensures that every dispense is sterile, precise, and protected. 3. Sustainability Meets Sophistication Minimal Waste, Maximum Yield In a world grappling with excess, airless packaging offers something radical: efficiency. These systems are designed for near-total evacuation. Every drop is dispensed, leaving no residual waste clinging to the walls of a bottle. That means consumers get more for their money—and less ends up in landfills. The reduction in product waste pairs with an increasing use of recyclable and reusable components. It’s sustainability without sacrifice. Precision, wrapped in conscience. for more inform : https://market.us/report/airless-packaging-market/ Eco-Luxury and the Rise of Smart Materials As luxury converges with environmental consciousness, packaging must evolve. Enter bio-resins, glass hybrids, and refillable cartridges—materials designed to impress without excess. Airless packaging now walks the fine line between indulgence and responsibility. No longer just utilitarian, it becomes an expression of ethical elegance. A modern emblem of brands that care about both people and planet. Conclusion Airless packaging is not a passing trend—it’s a tectonic shift. It redefines how products are preserved, how brands are perceived, and how sustainability is pursued. Oxygen, once an unavoidable enemy of longevity, is now outwitted by innovation. In this brave, sealed new world, airless is more than a dispenser—it's the future, pressurized and precises MARKET.USAirless Packaging MarketAirless Packaging Market size is expected to be worth around USD 11.3 Bn by 2034 from USD 6.7 Bn in 2024, growing at a CAGR of 5.4%.0 Comments 0 Shares 849 Views 0 ReviewsPlease log in to like, share and comment!

MARKET.USAirless Packaging MarketAirless Packaging Market size is expected to be worth around USD 11.3 Bn by 2034 from USD 6.7 Bn in 2024, growing at a CAGR of 5.4%.0 Comments 0 Shares 849 Views 0 ReviewsPlease log in to like, share and comment! -

Modern Logistics Powered by Plastic: The Industrial Shift Underway

The Transformation of Industrial Logistics Through Plastic Pallet Engineering

A Quiet Revolution in Supply Chains

Logistics, often described as the silent engine of commerce, is undergoing a metamorphosis. Hidden beneath container walls and conveyor belts lies a modest tool shaping this revolution: the pallet. Once an uncelebrated platform, it now stands at the epicenter of transformative engineering. The logistics industry is evolving—not with fanfare but with material mastery.

From Timber to Thermoplastics

Gone are the days when wood reigned supreme. The industry is now trading splinters for seamless polymeric platforms. The humble wooden pallet, while rugged and dependable, has ceded its dominance to plastic—sleeker, smarter, and significantly more strategic.

for more inform : https://market.us/report/plastic-pallet-market/

2. Historical Evolution of Industrial Pallets

The Wooden Workhorse Era

Since World War II, wooden pallets became the logistical backbone of global trade. Their charm lay in simplicity: easy to produce, easy to repair. But they also carried the burdens of splintering, susceptibility to moisture, and inconsistent sizing. Logistics managers tolerated inefficiencies as a cost of doing business.

Metal and Composite Interlude

As global trade grew in complexity, industries dabbled with metal and composite alternatives. Though offering strength, these iterations introduced their own dilemmas—weight, cost, and corrosion. It was clear: a new material had to rise—one both versatile and durable.

3. Rise of Plastic Pallet Engineering

The Science Behind the Shift

Plastic pallets are not mere substitutes; they are engineered evolutions. Behind each unit lies meticulous design rooted in thermodynamics, load distribution algorithms, and stress tolerance modeling. Engineers now treat pallets not as packaging tools, but as structural systems optimized for logistics.

Materials Innovation: From HDPE to Advanced Composites

High-Density Polyethylene (HDPE) became the pioneer polymer, prized for its resilience and cost-effectiveness. But the future lies in composites—hybrids of glass fiber, recycled plastics, and bio-polymers. These materials offer superior strength-to-weight ratios, anti-microbial properties, and thermal resistance suited for the most demanding supply chains.

4. Impact on Industrial Logistics

Durability and Lifecycle Optimization

Plastic pallets can endure thousands of shipping cycles without degradation. Unlike wood, they resist water, mold, and pest infestation. This resilience drastically extends their operational life—cutting replacement costs and minimizing disruption.

Standardization and Automation Compatibility

In the age of robotic forklifts and automated storage retrieval systems (ASRS), uniformity is king. Plastic pallets provide exact dimensions, consistent weight distribution, and RFID embedding capability—making them perfect allies of warehouse automation and global standard compliance.

for more inform : https://market.us/report/plastic-pallet-market/

5. Environmental and Economic Dimensions

Reusability, Recyclability, and Carbon Footprint

A single plastic pallet can outlast 100 wooden ones, slashing waste in high-frequency logistics. Many are made from post-consumer plastic and are fully recyclable at end-of-life. This circular approach not only trims carbon emissions but also aligns with stringent ESG frameworks.

Cost Efficiency in the Long Run

Though upfront investment is higher, plastic pallets prove fiscally wise over time. Lower maintenance, fewer replacements, and improved load safety mean reduced total cost of ownership. They are not expenses—they're logistical assets.

6. Innovations Reshaping the Sector

IoT-Enabled Smart Pallets

Some plastic pallets now speak—embedded with sensors that monitor humidity, temperature, location, and shock. These smart pallets offer real-time insights, reducing spoilage in perishable goods transport and enhancing supply chain transparency.

Customization for Niche Industries

From pharmaceutical-grade sterilizable pallets to fire-retardant versions for aerospace cargo, customization is the new frontier. Plastic’s moldability allows engineering firms to tailor pallets with industry-specific capabilities, transforming them into purpose-built instruments rather than generic tools.

7. Challenges and the Road Ahead

Initial Capital Costs and Adoption Barriers

Despite the benefits, sticker shock remains a hurdle. Smaller enterprises hesitate, deterred by the upfront cost. However, leasing models and pay-per-use programs are emerging to democratize access and accelerate adoption.

The Future: Circular Economy and Modular Design

What lies ahead is even more revolutionary. Imagine pallets that disassemble for recycling, track carbon credits in real time, or adapt in shape for multi-format packaging. The integration of circular economy principles with modular design is poised to redefine the essence of what a pallet can be.

Plastic pallet engineering is not merely a trend—it’s a tectonic shift. As industries pursue efficiency, sustainability, and precision, these engineered platforms are lifting far more than goods. They are elevating the entire logistics paradigm.

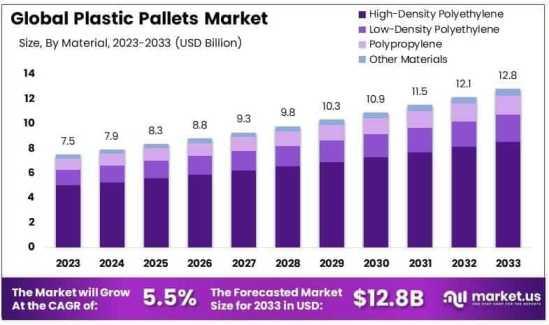

Modern Logistics Powered by Plastic: The Industrial Shift Underway The Transformation of Industrial Logistics Through Plastic Pallet Engineering A Quiet Revolution in Supply Chains Logistics, often described as the silent engine of commerce, is undergoing a metamorphosis. Hidden beneath container walls and conveyor belts lies a modest tool shaping this revolution: the pallet. Once an uncelebrated platform, it now stands at the epicenter of transformative engineering. The logistics industry is evolving—not with fanfare but with material mastery. From Timber to Thermoplastics Gone are the days when wood reigned supreme. The industry is now trading splinters for seamless polymeric platforms. The humble wooden pallet, while rugged and dependable, has ceded its dominance to plastic—sleeker, smarter, and significantly more strategic. for more inform : https://market.us/report/plastic-pallet-market/ 2. Historical Evolution of Industrial Pallets The Wooden Workhorse Era Since World War II, wooden pallets became the logistical backbone of global trade. Their charm lay in simplicity: easy to produce, easy to repair. But they also carried the burdens of splintering, susceptibility to moisture, and inconsistent sizing. Logistics managers tolerated inefficiencies as a cost of doing business. Metal and Composite Interlude As global trade grew in complexity, industries dabbled with metal and composite alternatives. Though offering strength, these iterations introduced their own dilemmas—weight, cost, and corrosion. It was clear: a new material had to rise—one both versatile and durable. 3. Rise of Plastic Pallet Engineering The Science Behind the Shift Plastic pallets are not mere substitutes; they are engineered evolutions. Behind each unit lies meticulous design rooted in thermodynamics, load distribution algorithms, and stress tolerance modeling. Engineers now treat pallets not as packaging tools, but as structural systems optimized for logistics. Materials Innovation: From HDPE to Advanced Composites High-Density Polyethylene (HDPE) became the pioneer polymer, prized for its resilience and cost-effectiveness. But the future lies in composites—hybrids of glass fiber, recycled plastics, and bio-polymers. These materials offer superior strength-to-weight ratios, anti-microbial properties, and thermal resistance suited for the most demanding supply chains. 4. Impact on Industrial Logistics Durability and Lifecycle Optimization Plastic pallets can endure thousands of shipping cycles without degradation. Unlike wood, they resist water, mold, and pest infestation. This resilience drastically extends their operational life—cutting replacement costs and minimizing disruption. Standardization and Automation Compatibility In the age of robotic forklifts and automated storage retrieval systems (ASRS), uniformity is king. Plastic pallets provide exact dimensions, consistent weight distribution, and RFID embedding capability—making them perfect allies of warehouse automation and global standard compliance. for more inform : https://market.us/report/plastic-pallet-market/ 5. Environmental and Economic Dimensions Reusability, Recyclability, and Carbon Footprint A single plastic pallet can outlast 100 wooden ones, slashing waste in high-frequency logistics. Many are made from post-consumer plastic and are fully recyclable at end-of-life. This circular approach not only trims carbon emissions but also aligns with stringent ESG frameworks. Cost Efficiency in the Long Run Though upfront investment is higher, plastic pallets prove fiscally wise over time. Lower maintenance, fewer replacements, and improved load safety mean reduced total cost of ownership. They are not expenses—they're logistical assets. 6. Innovations Reshaping the Sector IoT-Enabled Smart Pallets Some plastic pallets now speak—embedded with sensors that monitor humidity, temperature, location, and shock. These smart pallets offer real-time insights, reducing spoilage in perishable goods transport and enhancing supply chain transparency. Customization for Niche Industries From pharmaceutical-grade sterilizable pallets to fire-retardant versions for aerospace cargo, customization is the new frontier. Plastic’s moldability allows engineering firms to tailor pallets with industry-specific capabilities, transforming them into purpose-built instruments rather than generic tools. 7. Challenges and the Road Ahead Initial Capital Costs and Adoption Barriers Despite the benefits, sticker shock remains a hurdle. Smaller enterprises hesitate, deterred by the upfront cost. However, leasing models and pay-per-use programs are emerging to democratize access and accelerate adoption. The Future: Circular Economy and Modular Design What lies ahead is even more revolutionary. Imagine pallets that disassemble for recycling, track carbon credits in real time, or adapt in shape for multi-format packaging. The integration of circular economy principles with modular design is poised to redefine the essence of what a pallet can be. Plastic pallet engineering is not merely a trend—it’s a tectonic shift. As industries pursue efficiency, sustainability, and precision, these engineered platforms are lifting far more than goods. They are elevating the entire logistics paradigm.0 Comments 0 Shares 1K Views 0 Reviews -

Redefining Wrap: Biodegradable Packaging Takes Over

The Environmental Cost of Traditional Packaging

In a world increasingly aware of its ecological scars, packaging has emerged as a silent saboteur. It cushions, contains, and conveys—but at an astonishing cost. Conventional packaging, especially plastic, lingers in ecosystems for centuries, fragmenting into microplastics that weave through our oceans, soil, and bodies. The global packaging industry churns out billions of tons annually, and yet only a sliver is ever meaningfully recycled.

Beyond the visible pollution lies an even murkier problem: the carbon emissions tied to producing these materials. Petrochemical-based packaging isn’t just environmentally persistent—it’s carbon-intensive. Manufacturing, transportation, and disposal all contribute to a larger-than-expected footprint. In essence, every unassuming package might carry an unseen legacy of atmospheric harm.

for more inform : https://market.us/report/biodegradable-packaging-market/

Eco-Friendly Alternatives Redefining Packaging

The tide, however, is turning. From laboratories to farms, innovators are crafting materials that serve purpose without poisoning the planet. But in the realm of “eco-friendly,” terms are often used interchangeably. Understanding the difference between biodegradable and compostable is key. While both decompose, compostable materials do so within a specific timeframe under controlled conditions, returning nutrients to the soil. Biodegradable items might break down eventually—but without guarantees on time or residue.

Enter the new vanguard of materials:

Mushroom Packaging (Mycelium): This living material, grown from fungi roots, forms custom shapes by growing around molds. It’s lightweight, durable, and fully compostable within weeks.

Seaweed-Based Films: Derived from oceanic algae, these are edible, water-soluble, and dissolve harmlessly—ideal for single-serve food items.

Bagasse (Sugarcane Waste): The fibrous residue after extracting juice from sugarcane is now molded into sturdy containers and trays—offering resilience without plastic’s permanence.

Cornstarch Plastics (PLA): A plant-based polymer that mimics traditional plastics but decomposes in industrial composting environments.

These materials aren't mere substitutions; they’re a reimagining of packaging itself, one that aligns industrial need with environmental reverence.

Industry Sectors Leading the Sustainable Shift

Food & Beverage: Compostable Convenience

Disposable doesn’t have to mean destructive. Restaurants, cafes, and food delivery platforms are increasingly opting for compostable cutlery, containers, and cups. Chains like Just Salad and Sweetgreen are rolling out fully plant-based packaging. It's a shift born not just of ethics, but of economics—consumers are voting with their wallets, seeking brands that reflect their values.

Fashion & Retail: Packaging Meets Purpose

The fashion industry, once notorious for overpackaging, is experiencing a metamorphosis. Biodegradable garment bags, recyclable hangers, and algae-based inks are replacing toxic, non-degradable counterparts. Luxury labels are embracing minimalism—not just in design but in impact—crafting packages that biodegrade as gracefully as the clothes they protect.

E-commerce: Greener Logistics in the Digital Age

As the e-commerce boom barrels forward, so does the waste it generates. Forward-thinking brands are deploying corrugated boxes from recycled materials, mushroom foam insulation, and tape made from natural rubber. Even giants like Amazon are testing compostable mailers. This isn’t trend-chasing—it’s necessity in a world waking up to waste.

for more inform : https://market.us/report/biodegradable-packaging-market/

Toward a Circular Packaging Economy

The true promise of eco-friendly materials lies not just in what they are, but what they enable—a circular economy. This regenerative model designs packaging not for disposal, but for reintegration into the ecosystem or the economy.

Designing for end-of-life is becoming a design philosophy. Packaging engineers now work backwards—starting with how a product will return to the Earth, not just how it will protect what’s inside. This cradle-to-cradle thinking is fueling the development of smart packaging, which incorporates QR codes for recycling instructions or tracking materials' life cycles.

But the transition isn’t the burden of industry alone. Policy plays a pivotal role. Government mandates, plastic bans, and composting incentives are driving systemic change. Consumer education is another cornerstone. Even the greenest package is useless if tossed into the wrong bin.

Ultimately, it’s about a collective shift—from convenience at all costs to conscious creation and consumption. Packaging for the planet isn’t just a slogan—it’s a survival strategy, a declaration that design and degradation can coexist without ecological compromise.

The rise of eco-friendly packaging materials isn’t just about reducing waste. It signals a deeper evolution—a symbiosis between commerce and conservation, innovation and integrity. As we unbox the future, the question is no longer whether we can afford sustainable packaging, but whether we can afford anything

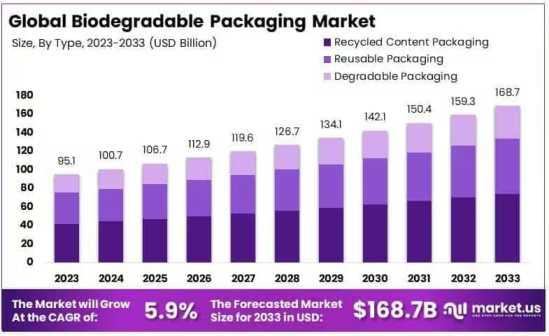

Redefining Wrap: Biodegradable Packaging Takes Over The Environmental Cost of Traditional Packaging In a world increasingly aware of its ecological scars, packaging has emerged as a silent saboteur. It cushions, contains, and conveys—but at an astonishing cost. Conventional packaging, especially plastic, lingers in ecosystems for centuries, fragmenting into microplastics that weave through our oceans, soil, and bodies. The global packaging industry churns out billions of tons annually, and yet only a sliver is ever meaningfully recycled. Beyond the visible pollution lies an even murkier problem: the carbon emissions tied to producing these materials. Petrochemical-based packaging isn’t just environmentally persistent—it’s carbon-intensive. Manufacturing, transportation, and disposal all contribute to a larger-than-expected footprint. In essence, every unassuming package might carry an unseen legacy of atmospheric harm. for more inform : https://market.us/report/biodegradable-packaging-market/ Eco-Friendly Alternatives Redefining Packaging The tide, however, is turning. From laboratories to farms, innovators are crafting materials that serve purpose without poisoning the planet. But in the realm of “eco-friendly,” terms are often used interchangeably. Understanding the difference between biodegradable and compostable is key. While both decompose, compostable materials do so within a specific timeframe under controlled conditions, returning nutrients to the soil. Biodegradable items might break down eventually—but without guarantees on time or residue. Enter the new vanguard of materials: Mushroom Packaging (Mycelium): This living material, grown from fungi roots, forms custom shapes by growing around molds. It’s lightweight, durable, and fully compostable within weeks. Seaweed-Based Films: Derived from oceanic algae, these are edible, water-soluble, and dissolve harmlessly—ideal for single-serve food items. Bagasse (Sugarcane Waste): The fibrous residue after extracting juice from sugarcane is now molded into sturdy containers and trays—offering resilience without plastic’s permanence. Cornstarch Plastics (PLA): A plant-based polymer that mimics traditional plastics but decomposes in industrial composting environments. These materials aren't mere substitutions; they’re a reimagining of packaging itself, one that aligns industrial need with environmental reverence. Industry Sectors Leading the Sustainable Shift Food & Beverage: Compostable Convenience Disposable doesn’t have to mean destructive. Restaurants, cafes, and food delivery platforms are increasingly opting for compostable cutlery, containers, and cups. Chains like Just Salad and Sweetgreen are rolling out fully plant-based packaging. It's a shift born not just of ethics, but of economics—consumers are voting with their wallets, seeking brands that reflect their values. Fashion & Retail: Packaging Meets Purpose The fashion industry, once notorious for overpackaging, is experiencing a metamorphosis. Biodegradable garment bags, recyclable hangers, and algae-based inks are replacing toxic, non-degradable counterparts. Luxury labels are embracing minimalism—not just in design but in impact—crafting packages that biodegrade as gracefully as the clothes they protect. E-commerce: Greener Logistics in the Digital Age As the e-commerce boom barrels forward, so does the waste it generates. Forward-thinking brands are deploying corrugated boxes from recycled materials, mushroom foam insulation, and tape made from natural rubber. Even giants like Amazon are testing compostable mailers. This isn’t trend-chasing—it’s necessity in a world waking up to waste. for more inform : https://market.us/report/biodegradable-packaging-market/ Toward a Circular Packaging Economy The true promise of eco-friendly materials lies not just in what they are, but what they enable—a circular economy. This regenerative model designs packaging not for disposal, but for reintegration into the ecosystem or the economy. Designing for end-of-life is becoming a design philosophy. Packaging engineers now work backwards—starting with how a product will return to the Earth, not just how it will protect what’s inside. This cradle-to-cradle thinking is fueling the development of smart packaging, which incorporates QR codes for recycling instructions or tracking materials' life cycles. But the transition isn’t the burden of industry alone. Policy plays a pivotal role. Government mandates, plastic bans, and composting incentives are driving systemic change. Consumer education is another cornerstone. Even the greenest package is useless if tossed into the wrong bin. Ultimately, it’s about a collective shift—from convenience at all costs to conscious creation and consumption. Packaging for the planet isn’t just a slogan—it’s a survival strategy, a declaration that design and degradation can coexist without ecological compromise. The rise of eco-friendly packaging materials isn’t just about reducing waste. It signals a deeper evolution—a symbiosis between commerce and conservation, innovation and integrity. As we unbox the future, the question is no longer whether we can afford sustainable packaging, but whether we can afford anything0 Comments 0 Shares 1K Views 0 Reviews -

Eco-Friendly Innovations in the Cosmetic Packaging IndustryThe Allure Beyond the Label Cosmetic packaging isn't merely a vessel—it’s a storyteller, a silent salesman, and a tactile experience wrapped in color and texture. In an industry built on desire and aesthetics, the packaging is often the first seduction. It whispers brand promises from store shelves and influencer videos alike, shaping perceptions long...0 Comments 0 Shares 882 Views 0 Reviews

-

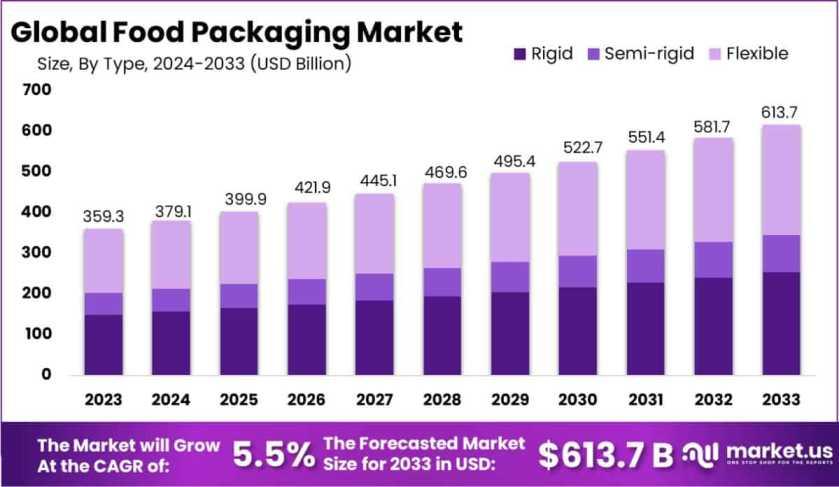

Food Packaging Market

Sustainable Packaging

Smart Food Packaging

Packaging Industry Trends

Eco-Friendly Food Packaging

Food Packaging Innovation

Global Packaging Market

For more inform ; https://market.us/report/food-packaging-market/Food Packaging Market Sustainable Packaging Smart Food Packaging Packaging Industry Trends Eco-Friendly Food Packaging Food Packaging Innovation Global Packaging Market For more inform ; https://market.us/report/food-packaging-market/File Type:0 Comments 0 Shares 365 Views 0 Reviews -

Eye Skin Care Products Market by Type, Application, and RegionGlobal Eye Skin Care Market Size, Share & Trends Analysis (2024–2033) The Eye Skin Care Market is undergoing a transformative evolution, fueled by innovation, consumer awareness, and a growing demand for specialized skincare products. According to recent projections, the global Eye Skin Care Market size is expected to reach USD 23.4 Billion by 2033, up from USD 14.2 Billion in...0 Comments 0 Shares 732 Views 0 Reviews

-

Eye Skin Care Products Market by Type, Application, and RegionGlobal Eye Skin Care Market Size, Share & Trends Analysis (2024–2033) The Eye Skin Care Market is undergoing a transformative evolution, fueled by innovation, consumer awareness, and a growing demand for specialized skincare products. According to recent projections, the global Eye Skin Care Market size is expected to reach USD 23.4 Billion by 2033, up from USD 14.2 Billion in...0 Comments 0 Shares 695 Views 0 Reviews

-

Eye Skin Care Products Market by Type, Application, and RegionGlobal Eye Skin Care Market Size, Share & Trends Analysis (2024–2033) The Eye Skin Care Market is undergoing a transformative evolution, fueled by innovation, consumer awareness, and a growing demand for specialized skincare products. According to recent projections, the global Eye Skin Care Market size is expected to reach USD 23.4 Billion by 2033, up from USD 14.2 Billion in...0 Comments 0 Shares 726 Views 0 Reviews

More Stories