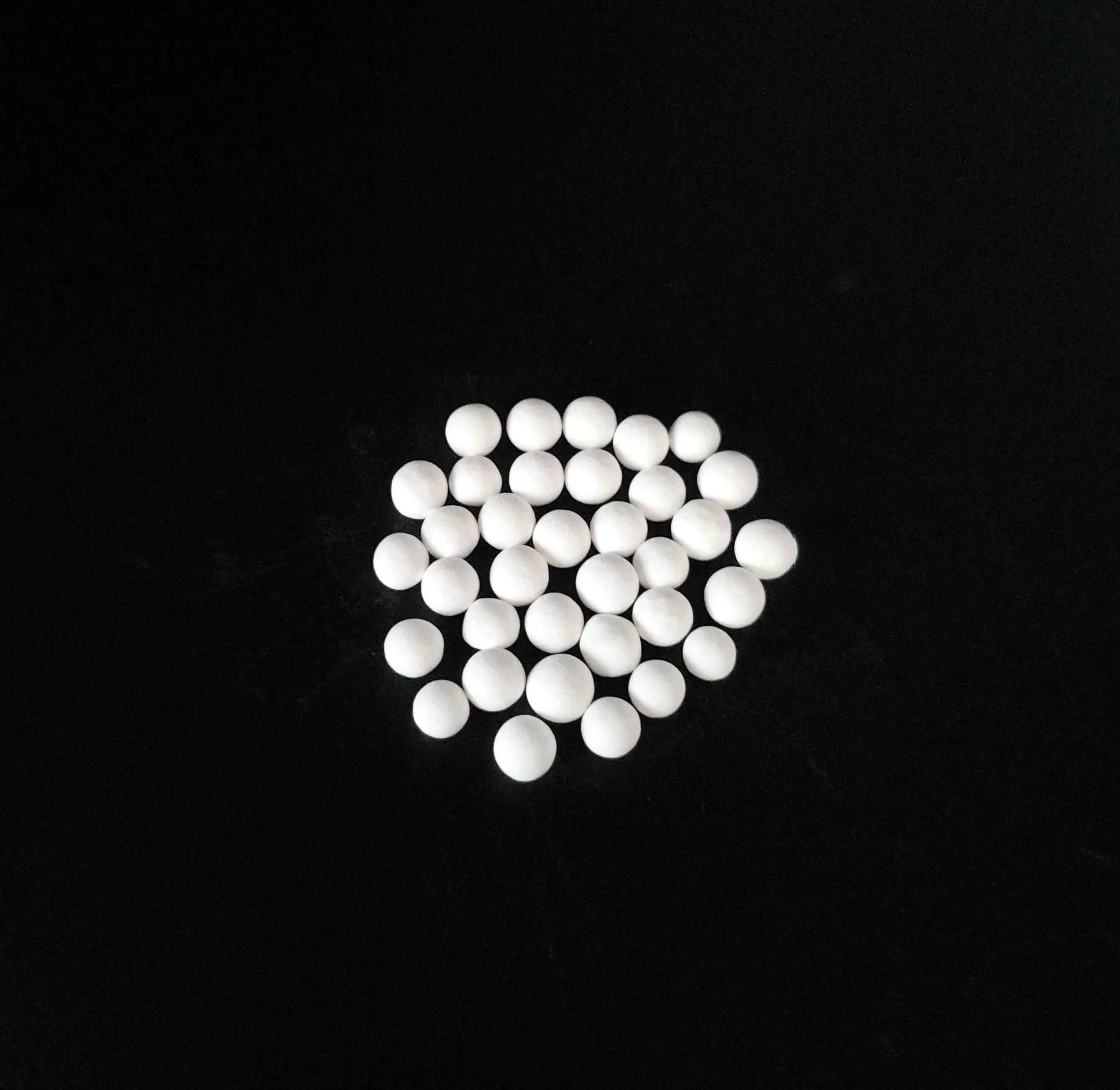

Exploring the Function of Activated Alumina Ball Carriers

Activated alumina ball carriers are versatile and widely used materials in various industries, particularly in the field of catalysis and adsorption. These carriers play a crucial role in supporting active catalysts and adsorbents, facilitating chemical reactions and the removal of impurities from process streams. In this blog, we will delve into the functions of activated alumina ball carriers, examining their properties, applications, and benefits in different industrial processes.

Properties of Activated Alumina Ball Carriers

Activated alumina ball carriers are composed of porous aluminum oxide particles that exhibit unique properties ideal for catalytic and adsorption applications. Some key properties of activated alumina ball carriers include:

High Surface Area: Activated alumina ball carriers have a high surface area per unit volume, providing ample active sites for catalytic reactions and adsorption processes. This property enhances the efficiency and effectiveness of the carriers in capturing or transforming target molecules.

Porous Structure: The porous structure of activated alumina ball carriers allows for the diffusion of reactants and products within the material, facilitating rapid mass transfer during chemical reactions. This property promotes high catalytic activity and adsorption capacity.

High Thermal Stability: Activated alumina ball carriers exhibit excellent thermal stability, enabling them to withstand high temperatures without undergoing significant physical or chemical changes. This property is essential for applications that involve elevated operating temperatures.

Chemical Inertness: Activated alumina ball carriers are chemically inert, meaning they do not react with most substances present in the process stream. This property ensures the stability and longevity of the carriers, preventing unwanted reactions or contamination.

Regenerability: Activated alumina ball carriers are regenerable, allowing them to be easily regenerated or rejuvenated after multiple cycles of use. This feature extends the lifespan of the carriers and reduces operational costs.

Functions of Activated Alumina Ball Carriers

Catalyst Support: One of the primary functions of activated alumina ball carriers is to support active catalysts in catalytic reactions. The carriers provide a stable and high-surface-area platform for catalyst deposition, promoting efficient contact between reactants and catalytic sites.

Adsorbent Material: Activated alumina ball carriers are used as adsorbents in adsorption processes to remove impurities, moisture, or specific molecules from gas or liquid streams. The porous structure of the carriers allows for the adsorption of target species through physical or chemical interactions.

Desiccant Media: Activated alumina ball carriers serve as desiccants in drying applications, where they selectively adsorb water vapor from air or gases. The high surface area and porosity of the carriers enable them to efficiently capture and retain moisture, ensuring the dryness of the process stream.

Gas Purification: Activated alumina ball carriers are employed in gas purification systems to remove contaminants, such as sulfur compounds, hydrocarbons, and volatile organic compounds (VOCs). The carriers adsorb these impurities, improving the quality and purity of the gas stream.

Regeneration Support: Activated alumina ball carriers play a crucial role in supporting the regeneration of spent catalysts or adsorbents. By providing a stable and inert support matrix, the carriers facilitate the regeneration process, allowing for the reuse of the active materials.

Conclusion

Activated alumina ball carriers are indispensable materials that play a vital role in catalytic reactions, adsorption processes, and purification applications across various industries. With their high surface area, porous structure, thermal stability, chemical inertness, and regenerability, activated alumina ball carriers offer unique properties that make them effective catalyst supports, adsorbents, desiccants, and purification media. From the petrochemical industry and environmental remediation to pharmaceutical manufacturing, natural gas processing, and air separation units, activated alumina ball carriers find diverse applications in enhancing process efficiency, product quality, and environmental sustainability.

Activated Alumina Ball Carriers: A Sustainable Solution for Air Filtration

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Jeux

- Gardening

- Health

- Domicile

- Literature

- Music

- Networking

- Autre

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness