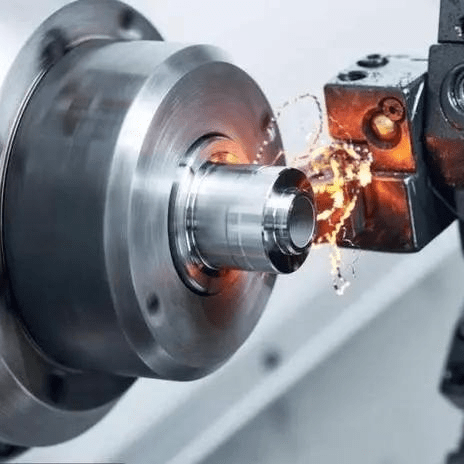

What Are Some of the Things to Consider When Designing Stainless Steel Parts for CNC Turning?

Several factors need to be carefully taken into account when designing stainless steel parts for CNC turning to guarantee the successful production of high-quality parts. Here are some key aspects to consider during the design process:

l Material Selection: Choosing the right grade of stainless steel is essential for the longevity and functionality of the CNC-turned parts. Considerations include the necessary strength, resistance to corrosion, ease of machining, and visual appeal. Selecting the right grade of stainless steel depends on the particular application as different grades have different properties.

l Part Geometry and Dimensions: It is important to consider the constraints of CNC turning when designing the part's geometry and dimensions. Take into account elements like feature complexity, wall thickness, and tool accessibility. Make sure the dimensions fall within the range of allowable tolerances and that the design permits sufficient clearance for cutting tools.

l Feature Design and Placement: CNC turning should be taken into consideration when designing each feature and where they should be placed on the part. Take into account elements like feature transitions, feature size, and feature orientation. Steer clear of deep pockets, extremely thin walls, and sharp internal corners as these could cause problems with machining.

l Surface Finish Requirements: The design documentation must specify the desired surface finish. Take into account elements like the part's intended use, the machining technique, and the tool choice. Different techniques can be used to achieve different surface finishes, so it is important to specify the desired level of aesthetics and smoothness.

l Tolerances and Specifications: Clearly state the part's critical dimensions and features, along with the tolerances and specifications. Take into account elements like the necessary precision, functional specifications, and production capacities. Indicate the tolerances that align with the overall design intent and can be achieved through CNC turning.

l Design for Manufacturability (DFM): Use DFM principles to make sure the design minimizes production challenges and is optimized for CNC turning. To expedite the machining process and cut down on waste, take into account elements like material properties, feature orientation, and tool accessibility.

Producing durable, affordable, and high-quality parts requires an understanding of the factors to be taken into account when designing stainless steel parts for CNC turning. It makes the machining process more effective, makes better use of the materials, makes sure that the assembly and integration are done correctly, and eventually produces longer-lasting and more effective products.

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Games

- Gardening

- Health

- Home

- Literature

- Music

- Networking

- Other

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness