An Overview of Lube Oil Blending Plants

Lube oil blending plants (LOBPs) are the backbone of the lubricant manufacturing industry, playing a pivotal role in producing high-quality oils for various applications. From automotive engines to industrial machinery, these plants ensure that lubricants meet the stringent requirements of modern technologies. But what exactly goes into the making of a lube oil blending plant? Let’s dive in to explore the intricate processes and significance of these facilities.

What Is a Lube Oil Blending Plant?

A lube oil blending plant is a facility where base oils and additives are combined to produce a wide range of lubricants. These include engine oils, gear oils, hydraulic fluids, and other specialty products. The blending process ensures that the final product meets industry-specific standards for performance, durability, and environmental compliance.

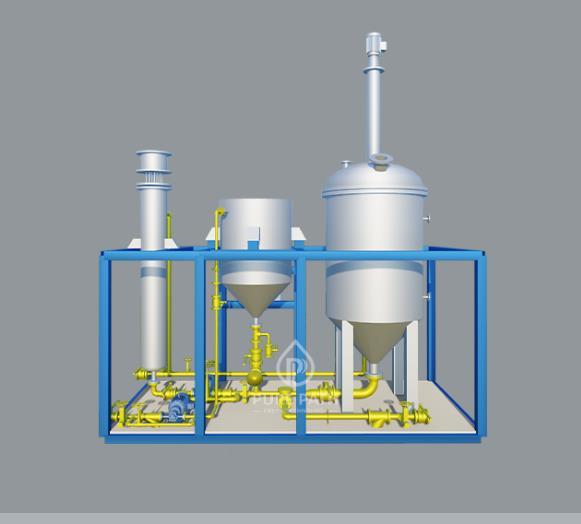

Key Components of a Lube Oil Blending Plant

Storage Tanks: Base oils and additives are stored in large tanks designed to maintain the integrity of raw materials.

Blending Units: These are the heart of the plant, where precise mixing of ingredients occurs. Blending can be done via batch or continuous processes, depending on the plant’s capacity and product requirements.

Heating Systems: Many base oils require heating to achieve optimal viscosity for blending.

Quality Control Labs: Ensuring product quality is paramount. Labs are equipped to test viscosity, thermal stability, and other critical parameters.

Packaging Lines: Once the blending process is complete, the lubricants are packaged in drums, cans, or bottles for distribution.

The Blending Process

Ingredient Selection: Based on the desired product, specific base oils and additives are chosen.

Heating and Mixing: Ingredients are heated and mixed under controlled conditions to ensure uniformity.

Quality Testing: Samples are tested to ensure the product meets all specifications.

Packaging and Distribution: The final product is packaged and dispatched to customers.

Why Are Lube Oil Blending Plants Important?

LOBPs contribute significantly to the economy by supporting industries such as automotive, aviation, marine, and manufacturing. They also play a crucial role in environmental protection by enabling the production of biodegradable and low-emission lubricants.

Future Trends

The industry is rapidly evolving, with automation, digitalization, and sustainability taking center stage. Modern LOBPs are integrating advanced technologies such as IoT and AI to enhance efficiency and reduce environmental impact.

Lube oil blending plants are not just factories; they are hubs of innovation and precision. Their contribution to global industries underscores their importance in the modern world.

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Jocuri

- Gardening

- Health

- Home

- Literature

- Music

- Networking

- Alte

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness