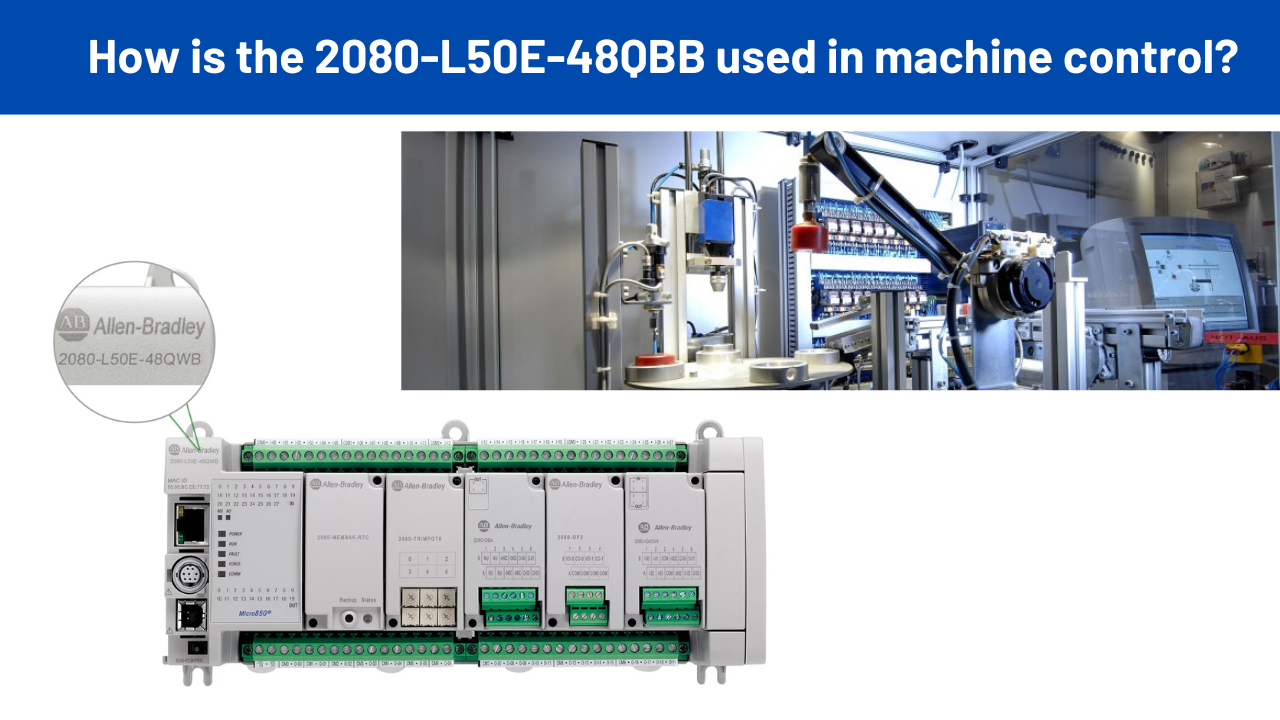

The Allen-Bradley 2080-L50E-48QBB is part of the Micro850 series and is commonly used in machine control applications, especially in small to medium-sized automation systems. Its features make it suitable for controlling machinery such as conveyors, automated assembly lines, packaging systems, and other industrial machines. Here's how it is typically applied:

Input/Output Handling:

The 2080-L50E-48QBB provides a combination of digital and analog I/O points, allowing it to interface with a variety of sensors, actuators, and other equipment that monitor and control machine functions. The digital I/O can handle on/off control signals for motors, switches, and relays, while the analog I/O supports continuous control for things like speed or pressure regulation.

Motion Control:

With its built-in support for pulse output, the Rockwell Automation 2080-L50E-48QBB can be used in motion control applications, such as controlling stepper motors, servo drives, or other motion devices, which is common in CNC machines or automated material handling systems.

Logic and Sequence Control:

This controller runs programs written in ladder logic, which is ideal for machine control tasks that require precise sequencing of operations, interlocking safety controls, or timed operations. For example, it can manage the start and stop sequences for a machine or control a specific sequence of operations based on sensor feedback.

Communication and Networking:

The 2080-L50E-48QBB supports Modbus and Ethernet/IP, which enables integration into larger control systems or communication with HMI (Human-Machine Interface) systems for operator interaction. It can also interface with other devices, such as VFDs (Variable Frequency Drives), temperature controllers, or barcode scanners, making it flexible in machine control environments.

Remote Monitoring and Control:

With the ability to support remote access through a web server or compatible software, operators can monitor the machine's performance, adjust settings, or troubleshoot remotely, improving efficiency and minimizing downtime.

Benefits of Using the 2080-L50E-48QBB in Machine Control

Enhanced Efficiency:

By automating repetitive and time-consuming tasks, the controller reduces cycle times and minimizes operational bottlenecks.

Improved Accuracy:

The high-speed processing capability of the 2080-L50E-48QBB ensures precise execution of machine functions, reducing errors and enhancing product quality.

Scalability:

As machine control needs evolve, the ability to add expansion modules or reprogram the controller ensures long-term adaptability.

Ease of Use:

The CCW software simplifies the setup and programming process, making it easier for engineers to deploy and maintain the controller.

Cost-Effectiveness:

By offering robust features at a competitive price point, the 2080-L50E-48QBB provides excellent value, especially for small to medium-sized machine control applications.

Check :- Allen Bradley Micro850 Programmable Controller

Applications of the 2080-L50E-48QBB in Machine Control

The Allen Bradley 2080-L50E-48QBB is versatile, making it ideal for various machine control applications across industries. Here are some notable use cases:

Packaging Machines

Packaging machines often involve multiple coordinated operations such as material feeding, cutting, sealing, and labeling. The 2080-L50E-48QBB excels in synchronizing these tasks by leveraging its high I/O count and real-time control capabilities. Its Ethernet connectivity facilitates communication with HMIs, enabling operators to monitor and adjust parameters on the fly.

Material Handling Systems

Conveyor systems, robotic arms, and pick-and-place machines rely on precise control to ensure smooth material handling. The 2080-L50E-48QBB integrates seamlessly with sensors and motor drives to optimize movement, reduce errors, and enhance throughput.

Automated Assembly Lines

Assembly lines require precise coordination of multiple components, including pneumatic actuators, stepper motors, and inspection systems. The 2080-L50E-48QBB’s ability to manage complex logic and its scalability make it an excellent choice for controlling such systems.

HVAC and Climate Control Systems

In machine control settings where environmental conditions such as temperature, humidity, or airflow are critical, the 2080-L50E-48QBB can manage and regulate these parameters effectively. Its analog input/output capabilities make it ideal for connecting temperature and pressure sensors.

Custom Machinery

For bespoke machines tailored to specific industrial applications, the 2080-L50E-48QBB offers flexibility in programming and configuration. Its expansion options and compatibility with various protocols enable it to accommodate unique requirements.

Integrating the 2080-L50E-48QBB with Other Systems

Machine control often involves multiple components working in unison. The Ethernet capability of the 2080-L50E-48QBB enables seamless integration with SCADA systems, distributed control systems (DCS), and HMIs. This interoperability allows operators to monitor performance, gather insights, and make data-driven decisions.

Additionally, the controller’s ability to support standard industrial communication protocols such as Modbus TCP/IP ensures compatibility with a wide range of devices, further enhancing its versatility.

Conclusion

The Allen Bradley 2080-L50E-48QBB is a robust and adaptable solution for machine control applications. Its combination of high I/O count, Ethernet connectivity, scalability, and ease of programming makes it a preferred choice for diverse industrial scenarios. Whether it’s managing packaging machines, optimizing assembly lines, or controlling custom machinery, this PLC delivers the precision and reliability required for modern manufacturing environments.