The 3D printing stainless steel market is evolving rapidly, driven by technological advancements, demand for customization, and its growing adoption across diverse industries. This transformation has led to a highly competitive landscape, where companies are constantly refining their strategies to maintain a competitive edge. Understanding the dynamics of this market is essential for stakeholders looking to capitalize on opportunities and navigate potential challenges. This article explores the key market dynamics, competitive landscape, and strategic moves that define the 3D printing stainless steel market.

Market Dynamics

-

Technological Advancements

The foundation of growth in the 3D printing stainless steel market lies in continuous technological advancements. Innovations such as increased printing speeds, improved material quality, and better precision have made 3D printing a more viable option for industrial-scale manufacturing. New hybrid systems, which combine additive and subtractive manufacturing processes, are also gaining traction. These technological developments enable companies to produce high-quality stainless steel parts with superior mechanical properties, better surface finishes, and more complex designs. As the technology evolves, it is expected that the speed, scalability, and cost-efficiency of 3D printing will continue to improve, enhancing the market's growth prospects. -

Customization and Complex Design Capabilities

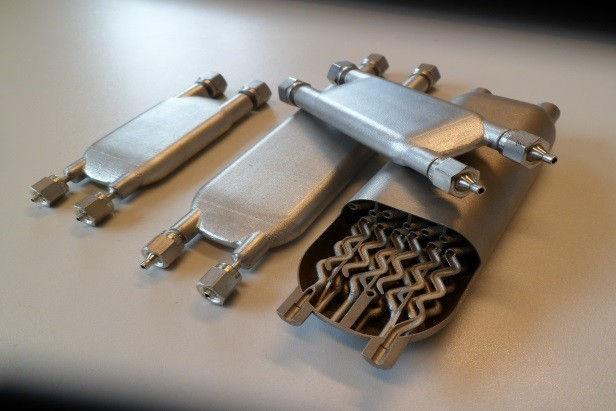

One of the driving forces behind the increasing adoption of 3D printing in stainless steel production is the ability to create customized parts with intricate geometries that are difficult to produce using traditional manufacturing methods. Industries such as aerospace, automotive, and healthcare benefit from 3D printing’s capacity to produce lightweight, durable, and tailored components. As demand for personalized products and efficient, on-demand manufacturing increases, companies are looking to leverage 3D printing to meet these needs, fostering market growth. -

Cost-Effectiveness and Material Waste Reduction

Cost-effectiveness is another key driver in the 3D printing stainless steel market. Unlike traditional methods that require expensive tooling, molds, and labor-intensive processes, 3D printing eliminates many of these steps, reducing production costs over the long term. Additionally, the technology’s layer-by-layer approach minimizes material waste, which is particularly important for industries where materials like stainless steel are costly. The ability to manufacture parts on demand further contributes to reducing inventory costs and streamlining production, making it an appealing solution for manufacturers seeking efficiency gains. -

Sustainability Initiatives

With increasing global attention on sustainability, 3D printing is gaining traction as a more eco-friendly manufacturing solution compared to traditional methods. The additive manufacturing process creates less waste, and the use of recycled stainless steel powder in 3D printing processes helps reduce environmental impact. As industries are pressured to adopt greener practices, the sustainability of 3D printing gives it a competitive advantage, further driving market growth.

Competitive Landscape

The 3D printing stainless steel market is characterized by a competitive landscape with a mix of established players and emerging companies. The major players in this market include 3D Systems, Stratasys, EOS GmbH, GE Additive, and SLM Solutions, among others. These companies are actively pursuing strategies to strengthen their position in the market, including investments in research and development, partnerships, and acquisitions.

-

Investment in R&D

Given the rapid technological evolution of 3D printing, companies are heavily investing in research and development to improve printer performance, material properties, and overall process efficiency. R&D initiatives focus on enhancing the strength, durability, and surface finish of printed stainless steel parts, making the technology more appealing for industrial applications. Companies are also working on expanding the range of materials available for 3D printing, which is expected to broaden the scope of the market. -

Strategic Partnerships and Collaborations

Strategic partnerships and collaborations are common in the 3D printing stainless steel market. Companies often collaborate with industry leaders and material suppliers to gain access to new technologies, research insights, and advanced materials. For example, partnerships between 3D printing companies and aerospace or automotive manufacturers help ensure that the technology meets the specific performance standards required by these industries. These collaborations enable faster adoption of 3D printing and expand its reach into new sectors. -

Acquisitions and Expansions

Acquisitions are another strategic move companies are using to enhance their market presence. By acquiring smaller or innovative 3D printing firms, larger companies can gain access to cutting-edge technologies or specific expertise in materials or production processes. Expanding product offerings through acquisitions enables companies to meet a broader range of customer needs and better compete in the growing 3D printing stainless steel market.

Strategic Moves and Future Outlook

As competition intensifies in the 3D printing stainless steel market, companies must focus on differentiation and innovation to stay ahead. This involves not only improving the technology itself but also enhancing customer service and establishing strong relationships within targeted industries. Companies may also look to expand into emerging markets, where 3D printing adoption is still in the early stages but growing rapidly.

In the long term, the market is expected to continue evolving as the cost of 3D printing technology decreases, and the capabilities of printers improve. New applications will likely emerge as industries discover the potential of 3D printing in stainless steel production, particularly in areas such as energy, consumer goods, and medical devices.

Overall, the 3D printing stainless steel market presents significant opportunities for businesses that can navigate the complexities of the competitive landscape. By leveraging technological advancements, expanding capabilities, and building strategic partnerships, companies can position themselves for sustained growth in this rapidly developing industry. The future of 3D printing stainless steel looks promising, with strong potential for long-term growth and transformation across a variety of sectors.