Muffle furnaces, known for their high-temperature heating capabilities, are indispensable tools in laboratories, catering to a wide range of applications. However, it's essential to use these furnaces correctly to prevent harm and ensure the safety of both operators and equipment. This article provides valuable insights into the structure, operation, and precautions associated with muffle furnaces.

Understanding the Structure of Muffle Furnaces

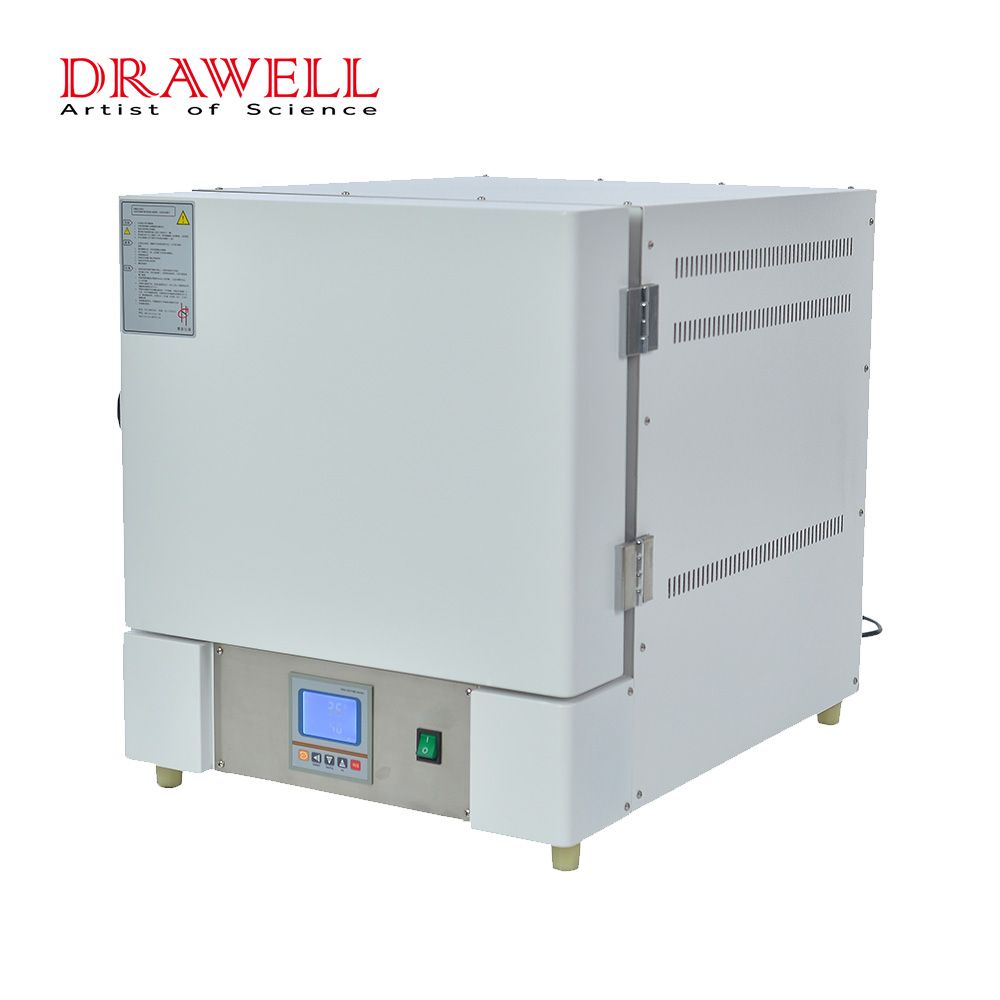

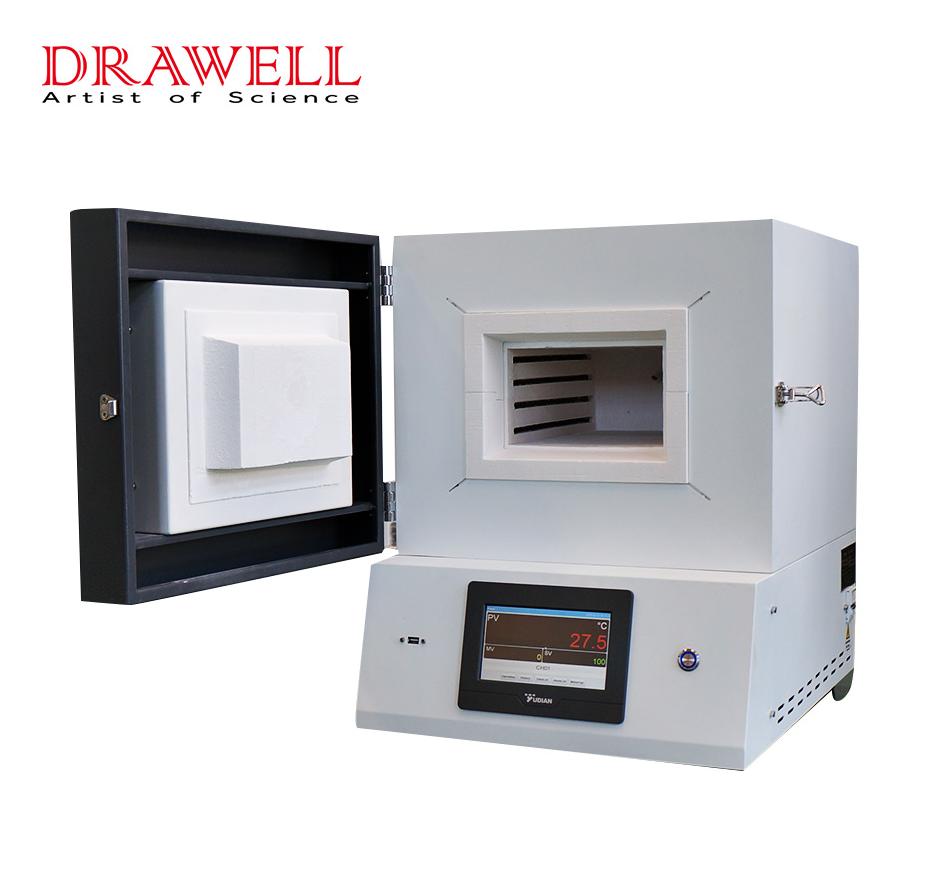

Muffle furnaces are typically box-shaped, designed for heating, heat preservation, and cooling processes. They feature a single door or slot for feeding and discharging materials, making them easy to operate and maintain.

The furnace itself is constructed with a stainless steel plate and includes a heating and hot air circulation chamber. This design allows for improved temperature uniformity within the furnace, making it ideal for a wide range of heat treatment processes.

The separation of the furnace chamber and frame is a notable feature, with the chamber placed on load-bearing rollers at the bottom of the frame. This design enables free movement along the length direction during heating, ensuring even heat distribution.

To prevent hot gas leakage from the furnace, there are two layers of seals at the furnace door. The inner seal consists of a ceramic fiber rope, while the outer seal employs a silicone rubber sealing ring. To extend the seals' lifespan, a stainless steel cooling water jacket is integrated into the furnace door seal for cooling. The door lock mechanism features a multi-point handwheel rotation locking system, providing uniform locking around the door. Additionally, a furnace door fixing device is installed on the furnace chamber's end face, utilizing a movable double-hinge mechanism to move seamlessly with the furnace's extension, thereby enhancing the sealing effect.

How to Operate a Muffle Furnace

Initial Inspection:

When your muffle furnace arrives, conduct a thorough inspection to check for any damage and ensure all accessories are present. The furnace typically requires no special installation and can be placed on a flat, stable surface. Keep the controller away from vibration and avoid placing it too close to the furnace to prevent overheating of internal components. Thermocouple Placement:

Insert a thermocouple into the furnace, ensuring it extends 20-50mm into the chamber. Fill any gap around the hole with asbestos rope. Ideally, use a compensation wire to connect the thermocouple to the controller, taking care to observe the correct polarity.

Safety Precautions:

Install a power switch at the power line's inlet to control the main power supply. Proper grounding of the electric furnace and controller is crucial for safe operation. Temperature Indicator Calibration:

Before use, calibrate the thermometer indicator to zero. If using a compensating wire and cold end compensator, adjust the mechanical zero point to match the cold end compensator's reference temperature. Without a compensating wire, adjust the mechanical zero point to the zero scale, noting that the indicated temperature represents the temperature difference between the measuring point and the thermocouple's cold end. Initial Heating:

After confirming the correct wiring and calibration, cover the controller housing. Adjust the temperature indicator's setting pointer to the desired operating temperature, and then power on the furnace using the power switch. The green light on the temperature indicator should illuminate, and the relay will start working. The ammeter will display the current, and as the furnace's internal temperature rises, the temperature indicator's pointer will gradually ascend. The green light indicates the temperature is rising, while the red light signifies the furnace is at a constant temperature.

Precautions for Muffle Furnace Operation

Stable Placement:

Always place the muffle furnace on a stable cement platform, with appropriate plugs, sockets, and fuses. Ensure proper grounding to avoid potential hazards. Safe Environment:

The working environment should be free of flammable substances, explosive materials, and corrosive gases. Avoid baking liquid samples like water and oil directly, and refrain from pouring various liquids or molten metals into the furnace to maintain cleanliness. Temperature Limits:

Do not exceed the furnace chamber's maximum temperature, and avoid prolonged operation at the rated temperature. During operation, remain present and vigilant to any temperature fluctuations. If abnormalities occur, immediately disconnect the power and seek professional maintenance. Gentle Handling:

Close the furnace door gently to prevent damage to the furnace components. When handling samples, use a crucible clamp with care to avoid damage to the furnace chamber. Avoid Opening at High Temperatures:

Do not open the furnace door when the temperature exceeds 600°C. Wait for the furnace to naturally cool down before accessing the interior. Safety during Sample Handling:

After an experiment, remove the sample from heating and turn off the power supply. When placing a sample into the muffle furnace, slightly open the furnace door and wait for the sample to cool before carefully securing it to prevent burns.

Prevent Moisture Damage:

When not in use, disconnect the power supply and close the furnace door to prevent moisture from eroding the refractory components.

By following these guidelines and adhering to safety precautions, you can effectively and safely operate a muffle furnace, whether in a laboratory, industrial setting, or any other application requiring high-temperature heating. Proper handling and maintenance will ensure the longevity and reliability of your muffle furnace.