Electrostatic Discharge Packaging Market Growth: Key Trends and Future Outlook for Electronics Packaging Solutions.

Electrostatic discharge (ESD) is a significant concern in various industries, particularly in electronics manufacturing, where even the smallest static charge can damage sensitive components. As technology advances and electronic devices become increasingly compact, the need for effective ESD protection is more critical than ever. The Electrostatic Discharge (ESD) Packaging Market, therefore, plays a pivotal role in safeguarding electronics during transportation, handling, and storage processes. This market is expanding steadily, driven by increasing electronics production, growing awareness of ESD risks, and innovations in packaging solutions.

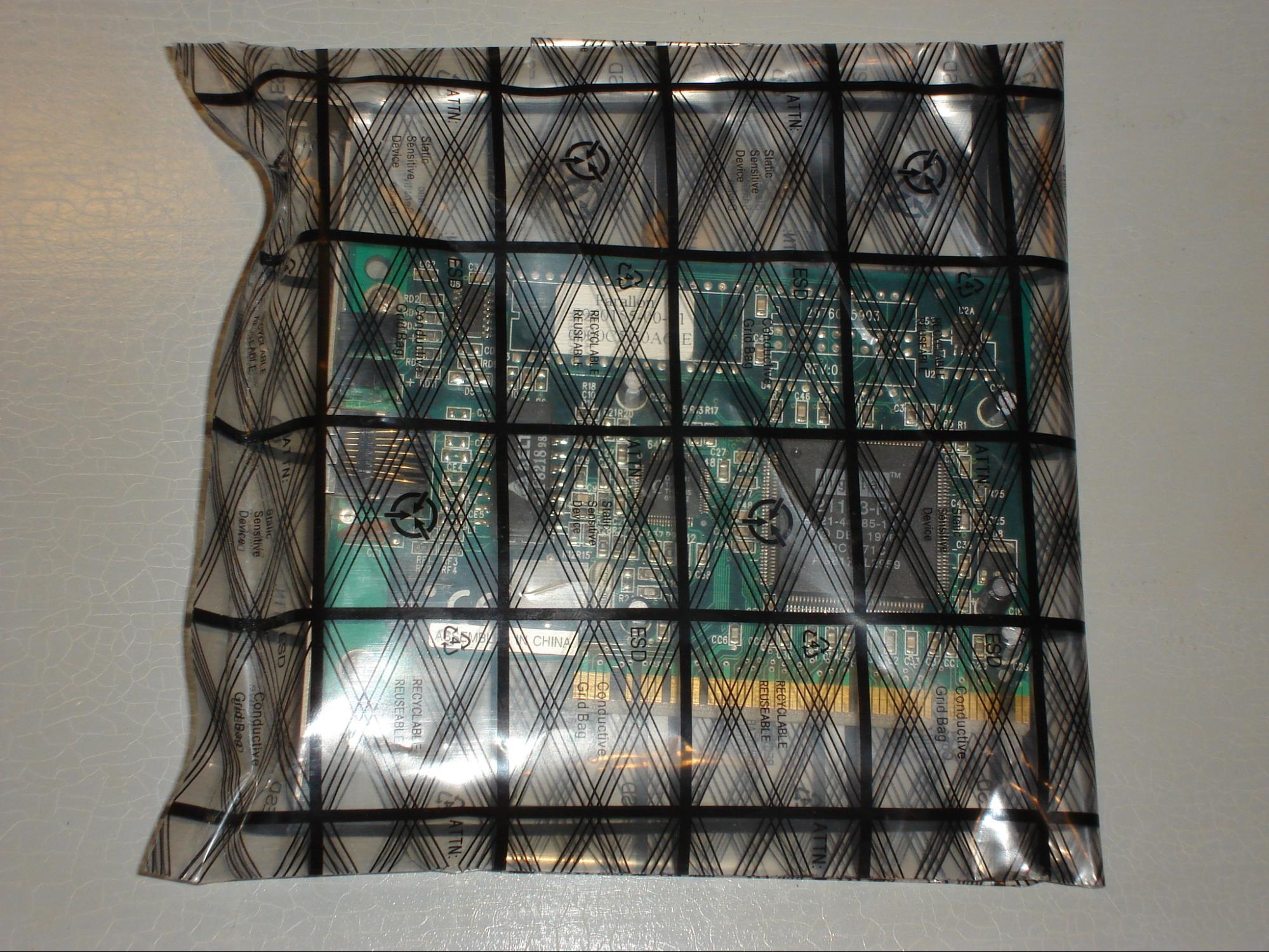

Market Overview: Electrostatic Discharge Packaging refers to the specialized materials and containers used to protect electronic devices from electrostatic charge buildup that could harm electronic circuits. These packaging materials include conductive, static dissipative, and insulative materials that are carefully designed to neutralize and minimize ESD. Popular solutions include ESD-safe bags, trays, boxes, and wraps, which are used throughout the supply chain from manufacturers to end-users.

The market’s growth is largely influenced by the rapid increase in the consumption of electronic products, particularly semiconductors, consumer electronics, telecommunications equipment, and automotive electronics. Devices such as smartphones, computers, LEDs, circuit boards, and medical equipment are particularly vulnerable to electrostatic discharge, necessitating efficient packaging solutions to prevent damage during manufacturing or transit.

Key Drivers: Several factors are accelerating the growth of the ESD packaging market:

- Growing Electronics Production: The ever-growing demand for advanced consumer electronics and electric vehicles has bolstered the need for high-quality ESD protection.

- Increased Awareness of ESD Hazards: As industries become more aware of the costs associated with static damage, investing in proper packaging solutions is now seen as a must, not a luxury.

- Technological Advancements in Packaging Materials: The introduction of newer, more effective ESD packaging materials is pushing the market further, especially with materials offering enhanced durability and protection.

- Government Regulations and Standards: In many regions, electronic products must meet strict standards and certifications regarding ESD safety, further driving the adoption of specialized packaging.

- Surging Demand in Developing Regions: Rapid industrialization in emerging economies has expanded the demand for ESD packaging, particularly within the automotive and telecom sectors.

Types of ESD Packaging: The ESD packaging market encompasses several categories, each catering to different aspects of the electronic product handling:

- ESD Bags: The most common solution, typically used for components like ICs and semiconductor devices. These bags are usually made from metalized polypropylene and are available in static dissipative or conductive variations.

- ESD Trays and Boxes: Designed to store and organize sensitive products, these are often made of conductive plastic or foam material that maintains a neutral electric charge.

- ESD Bubble Wraps: Used to cushion fragile components, these wraps dissipate static charges to protect products during shipping.

- ESD Foam: Typically used for cushioning and preventing contact between components during storage and transport, these foams come in customizable sizes.

Market Challenges: Despite the significant market growth, several challenges remain. A key challenge is the cost associated with high-quality ESD packaging. As production processes evolve and packaging materials improve, maintaining cost efficiency while ensuring the effectiveness of the packaging is a concern for manufacturers. Additionally, ensuring global compliance with varying standards and regulations in different regions can be a complex task.

The rise of counterfeit products is another issue that the market faces, as improper ESD packaging may lead to a lack of protection. As counterfeit electronic products become more common, the demand for authentic and regulated ESD packaging solutions rises in an effort to preserve product integrity.

Future Outlook: The future of the Electrostatic Discharge Packaging Market appears promising with continued innovation and demand. As industries expand and diversify, so does the need for better and more efficient packaging. The advent of new materials and smarter packaging solutions are likely to play a central role in shaping the future landscape of the market. Moreover, as consumer electronics and automotive industries evolve, the demand for reliable ESD protection will become even more pronounced.

In conclusion, ESD packaging is no longer a niche market, but an integral component of the electronics supply chain. As we look ahead, the sector is positioned to witness robust growth, driven by a combination of technological innovation, demand from high-tech industries, and increased regulatory emphasis on ESD standards.

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Jocuri

- Gardening

- Health

- Home

- Literature

- Music

- Networking

- Alte

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness