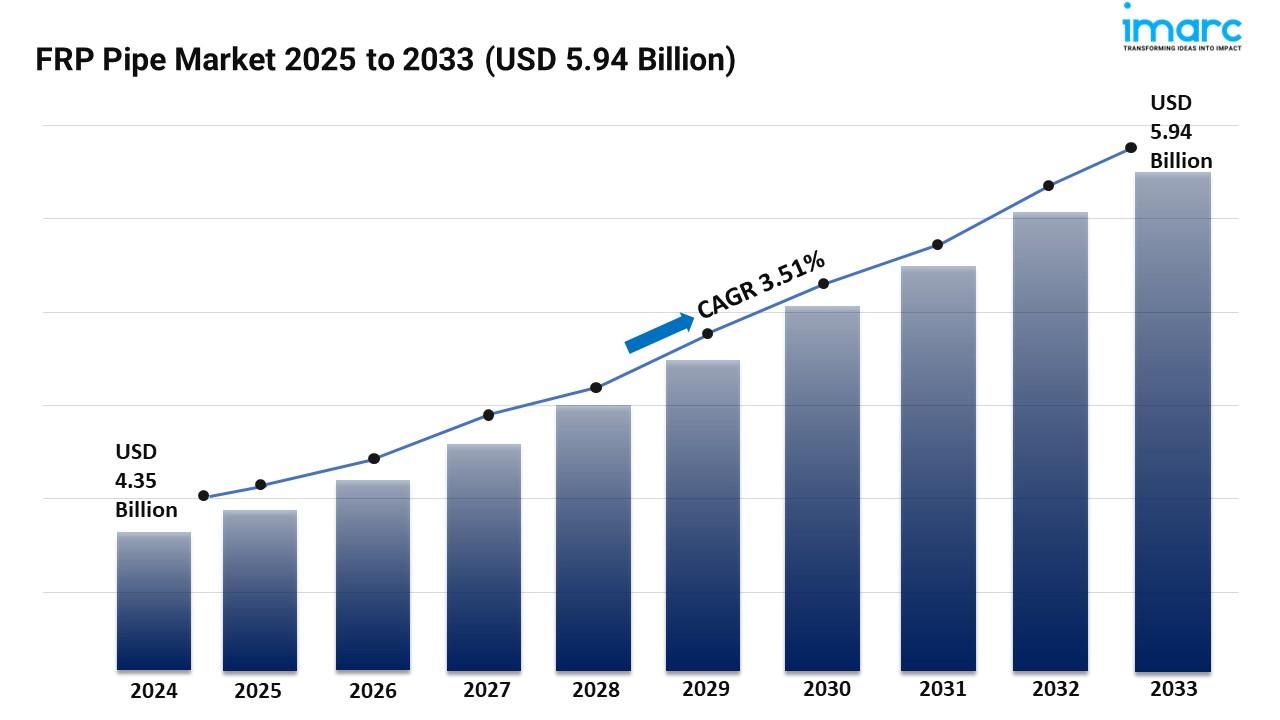

Global FRP Pipe Market Statistics: USD 5.94 Billion Value by 2033

Summary:

- The global FRP pipe market size reached USD 4.35 Billion in 2024.

- The market is expected to reach USD 5.94 Billion by 2033, exhibiting a growth rate (CAGR) of 3.51% during 2025-2033.

- Asia Pacific leads the market, accounting for the largest FRP pipe market share.

- Glass-reinforced epoxy holds the majority of the market share in the type segment, as they are highly suitable for demanding applications in sectors like oil and gas and water treatment.

- Filament winding exhibits a clear dominance in the FRP pipe industry.

- Based on the application, the market has been divided into water and wastewater, chemical and industrial, oil and gas, power generation, and others.

- The rising number of renewable energy initiatives is a primary driver of the FRP pipe market.

- The increasing infrastructure development and corrosion resistance are reshaping the FRP pipe market.

Industry Trends and Drivers:

- Corrosion resistance:

FRP pipes do not corrode with chemicals, seawater and abrasive materials. In contrast to steel or concrete, for example, they do not wear out. This means that the materials will not be replaced as often, or repaired, which reduces long-term expenditure. Especially appreciated by water treatment services, oil and gas products, chemical industries. Environmental conditions of their locations are abrasive. Conventional pipe systems are actually subjected to strong chemicals, heavy acid, alkali and high salinity. Corrosion results in leakage, extended(stoppage) time, and problems concerning safety. This is dangerous to the environment and the workers as well. FRP pipes are hence used providing a reliable solution, free from failure and contamination issues.

- Growing infrastructure development:

Cities are rising and countries are improving their water management systems to cope with this reality. This increases the need for credible pipes that are able to resist corrosion. FRP pipes have high strength and are used where smooth inner liner for the passage of water, sewage or other compatible fluids. They are now preferred and admired for undertaking water ventures in cities and industries. In the global arena, there is also gradually increasing demand for oil and gas on the global market. This result in huge investments in pipelines as a means of extraction and distribution. Image 2 for these needs, especially where corrosive or high pressure is involved, FRP pipes are suitable. These are easy to handle, cheaper, and can stand hard use and conditions. As such, they are finding application in oil and gas projects.

- Renewable energy initiatives:

Offshore wind farms, geothermal systems, and others are exposed to severe circumstances. They are subjected to chemicals, humidity and marine water. For these systems, therefore, FRP pipes are most suitable. It is considered that they are less sensitive to corrosion in comparison with metal pipes. This will keep the costs of maintenance down, and it also increases the lifespan of the system. Therefore, developers like to use on FRP pipes than using other materials. Further, FRP pipes are very light but are known to have very high strength. This makes them ideal for renewable energy project as they have the following attributes; In the offshore wind farms the turbines makes it easier to be transported and installed. Due to high strength to weight ratio, FRP pipes can be easily lifted and transported compared to other pipes material. As for large projects which are built in remote areas, this can be big advantage.

Request for a sample copy of this report: https://www.imarcgroup.com/frp-pipe-market/requestsample

FRP Pipe Market Report Segmentation:

Breakup By Type:

- Glass-Reinforced Polyester

- Glass-Reinforced Vinyl Ester

- Glass-Reinforced Epoxy

Glass-reinforced epoxy represents the largest segment as it offers a high strength-to-weight ratio and excellent corrosion resistance.

Breakup By Manufacturing Process:

- Centrifugal Casting

- Filament Winding

- Pultrusion

- Others

Filament winding accounts for the majority of the market share: The Filament Winding process provides consistent quality, cost-effectiveness, and high-strength characteristics, making it ideal for producing FRP pipes in large volumes for industrial applications.

Breakup By Application:

- Water and Wastewater

- Chemical and Industrial

- Oil and Gas

- Power Generation

- Others

Based on the application, the market has been divided into water and wastewater, chemical and industrial, oil and gas, power generation, and others.

Breakup By Region:

- North America (United States, Canada)

- Asia Pacific (China, Japan, India, South Korea, Australia, Indonesia, Others)

- Europe (Germany, France, United Kingdom, Italy, Spain, Russia, Others)

- Latin America (Brazil, Mexico, Others)

- Middle East and Africa

Asia Pacific enjoys the leading position in the FRP pipe market on account of its rapid infrastructure development, industrial expansion, and increasing investments in renewable energy.

Top FRP Pipe Market Leaders:

The FRP pipe market research report outlines a detailed analysis of the competitive landscape, offering in-depth profiles of major companies. Some of the key players in the market are:

- Augusta Fiberglass

- Enduro Composites

- Ershigs Inc

- Fibrex Fiberglass Pipe

- FRP SYSTEMS

- Hanwei Energy Services Corp.

- HOBAS

- Industrial Plastic Systems

- Lianyungang Zhongfu Lianzhong Composites Group Co. Ltd

- NOV Inc.

- Sarplast

- Saudi Arabian Amiantit Co.

- Shawcor Ltd.

Note: If you require any specific information that is not covered currently within the scope of the report, we will provide the same as a part of the customization.

About Us:

IMARC Group is a global management consulting firm that helps the world’s most ambitious changemakers to create a lasting impact. The company provide a comprehensive suite of market entry and expansion services. IMARC offerings include thorough market assessment, feasibility studies, company incorporation assistance, factory setup support, regulatory approvals and licensing navigation, branding, marketing and sales strategies, competitive landscape and benchmarking analyses, pricing and cost research, and procurement research.

Contact Us:

IMARC Group

134 N 4th St. Brooklyn, NY 11249, USA

Email: sales@imarcgroup.com

Tel No:(D) +91 120 433 0800

United States: +1-631-791-1145