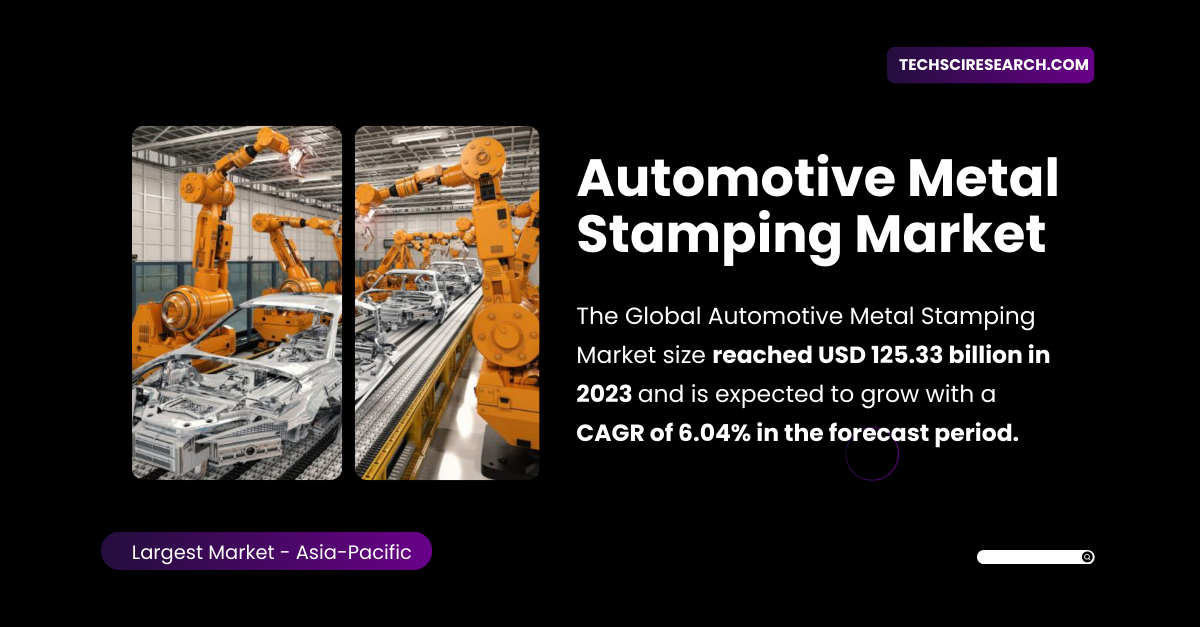

According to the TechSci Research report titled “Automotive Metal Stamping Market – Global Industry Size, Share, Trends, Competition Forecast & Opportunities, 2029F,” the Global Automotive Metal Stamping Market reached a valuation of USD 125.33 billion in 2023 and is projected to grow to USD 177.96 billion by 2029, registering a compound annual growth rate (CAGR) of 6.04% during the forecast period.

This growth is attributed to rising demand for lightweight vehicles, cost-effective production methods, and advancements in stamping technologies.

Key Automotive Metal Stamping Market Drivers

- Increasing Demand for Lightweight Vehicles

Stricter environmental regulations and consumer demand for fuel-efficient vehicles are driving automakers to adopt lightweight materials such as aluminum and high-strength steel. Metal stamping is central to producing these materials in a cost-effective and efficient manner.

- Advancements in Stamping Technologies

The integration of automation, robotics, and smart manufacturing systems in metal stamping processes is enhancing production accuracy, reducing material waste, and improving operational efficiency. These advancements are crucial for meeting the increasing complexity of automotive components.

- Growth of Electric Vehicles (EVs)

The rise in electric vehicle adoption is significantly influencing the automotive metal stamping industry. EVs require specialized stamped components, including lightweight battery enclosures and structural elements, to enhance energy efficiency and reduce overall vehicle weight.

Browse over XX market data Figures spread through XX Pages and an in-depth TOC on "Global Automotive Metal Stamping Market.” @ https://www.techsciresearch.com/report/automotive-metal-stamping-market/19257.html

Automotive Metal Stamping Market Segmentation

By Vehicle Type

The automotive metal stamping market is segmented into passenger cars and commercial vehicles.

-

Passenger Cars

-

Passenger cars represent the largest segment of the market. Diverse consumer preferences, ranging from compact cars to luxury sedans and electric vehicles, drive demand for various stamped metal parts such as body panels and chassis components.

-

Automakers are leveraging metal stamping technologies to produce lightweight, high-strength parts that improve fuel efficiency and safety standards.

-

-

Commercial Vehicles

-

Commercial vehicles, including trucks, buses, and vans, require robust and durable components. Metal stamping fulfills the need for frame components, body panels, and structural reinforcements capable of handling heavy loads.

-

Growth in logistics, transportation, and construction industries further fuels demand for stamped metal parts in this segment.

-

By Technology

The market is segmented by technology into the following categories:

-

Blanking

-

Used for creating precise shapes and reducing material waste.

-

-

Embossing

-

Enhances the aesthetics and functionality of components.

-

-

Coining

-

Provides high-precision stamping for smaller components.

-

-

Flanging

-

Improves the strength and rigidity of components.

-

-

Bending

-

Used in creating complex geometries.

-

-

Other Technologies

-

Includes a variety of specialized processes tailored to unique automotive needs.

-

By Process

Key processes in the automotive metal stamping market include:

-

Roll Forming

-

Used for creating long, continuous shapes with consistent cross-sections.

-

-

Hot Stamping

-

Offers strength enhancement and weight reduction, making it ideal for high-strength steel components.

-

-

Sheet Metal Forming

-

Enables flexibility in creating complex designs.

-

-

Metal Fabrication

-

Focused on assembling stamped parts into final components.

-

-

Other Processes

-

Includes innovative and emerging stamping techniques.

-

Automotive Metal Stamping Market Regional Analysis

Asia-Pacific: The Fastest Growing Region

Asia-Pacific emerged as the fastest-growing region in the global automotive metal stamping market in 2023. Several factors contribute to this growth:

-

Rapid Industrialization

-

Countries such as China, India, Japan, and South Korea are witnessing significant industrial and automotive production growth.

-

-

Rise in EV Production

-

The region’s commitment to sustainability and the adoption of electric vehicles drive demand for advanced stamping solutions to create lightweight and high-performance components.

-

-

Adoption of Automation

-

Manufacturers are increasingly utilizing automated and smart manufacturing systems to enhance production efficiency and meet the demand for intricate designs.

-

Other Key Regions

-

North America

-

The region remains a major player due to strong investments in automotive manufacturing and advanced production technologies.

-

-

Europe

-

Focuses on sustainability and the production of premium electric vehicles.

-

-

Rest of the World

-

Regions such as Latin America and the Middle East are emerging markets with increasing automotive production and infrastructure development.

-

Emerging Trends in Automotive Metal Stamping Market

Adoption of Automation and Robotics

The integration of robotic systems and digital technologies is transforming the automotive metal stamping industry. Automation enhances production speed, reduces errors, and lowers operational costs.

Advanced Materials

The use of lightweight and high-strength materials such as aluminum and composites is reshaping the stamping process, making it suitable for modern vehicle designs.

EV-Specific Innovations

The shift towards electric vehicles is prompting the development of specialized stamping techniques to accommodate new materials and designs. Lightweight battery enclosures and energy-efficient structural components are among the focus areas.

Sustainability Initiatives

Automotive manufacturers are emphasizing eco-friendly practices, including cleaner production processes and the use of recyclable materials, to meet global environmental standards.

Automotive Metal Stamping Market Competitive Landscape

Major companies operating in the global automotive metal stamping market include:

-

Clow Stamping Company

-

Specializes in custom stamping solutions with a focus on quality and precision.

-

-

D&H Industries, Inc.

-

Offers diverse metal stamping services to meet evolving automotive needs.

-

-

Magna International Inc.

-

A global leader in automotive manufacturing, with expertise in innovative stamping technologies.

-

-

PDQ Tool & Stamping Co.

-

Known for cost-effective and high-precision stamping solutions.

-

-

Hyundai Mobis Co., Ltd.

-

Focuses on advanced stamping techniques for EV and autonomous vehicle components.

-

-

WIEGEL TOOL WORKS, INC.

-

Provides specialized stamping solutions for complex automotive parts.

-

-

Manor Tool & Manufacturing Company

-

Offers customized metal stamping services with a focus on innovation.

-

-

Arconic Corporation

-

A leader in lightweight materials and precision stamping.

-

-

American Industrial Co.

-

Known for its high-quality stamping solutions for the automotive sector.

-

-

Tempco Manufacturing Company, Inc.

-

Specializes in metal stamping and fabrication for various automotive applications.

-

Download Free Sample Report @ https://www.techsciresearch.com/sample-report.aspx?cid=19257

Customers can also request 10% free customization on this report.

Recent Developments

In 2024, Tenral launched precision metal stamping solutions, combining high quality with cost-effectiveness. This initiative aims to meet the diverse demands for precise metal components, reinforcing Tenral’s commitment to advancing manufacturing capabilities.

Future Outlook of the Automotive Metal Stamping Market

The automotive metal stamping market is poised for significant growth, driven by:

-

Technological Advancements

-

Innovations such as hot stamping and robotic automation will continue to enhance efficiency and precision.

-

-

EV Adoption

-

The rise of electric vehicles will necessitate new stamping solutions tailored to lightweight and energy-efficient designs.

-

-

Sustainability

-

Eco-friendly manufacturing practices and recyclable materials will become central to the market’s evolution.

-

Conclusion

The global automotive metal stamping market is undergoing rapid transformation, fueled by the demand for lightweight vehicles, advancements in technology, and the shift toward electric mobility.

With strong growth projected through 2029, the industry is set to play a critical role in shaping the future of automotive manufacturing.

Stakeholders must focus on innovation, sustainability, and efficiency to capitalize on the opportunities in this dynamic market.

You may also read:

Automotive Interior Leather Market Trends and Forecast [CAGR: 5.59%] through 2029

LED Fog Lamp Market to Witness Significant Growth: [7.59% CAGR] and USD 2.81 Billion by 2029

Bike Sharing Market: Future Outlook, Key Players, Trends, and USD 4.32 Billion Valuation by 2029 (CAGR: 5.83%)

Automotive Lithium-Ion Battery Market Report: USD 45.27B and 7.05% CAGR by 2029