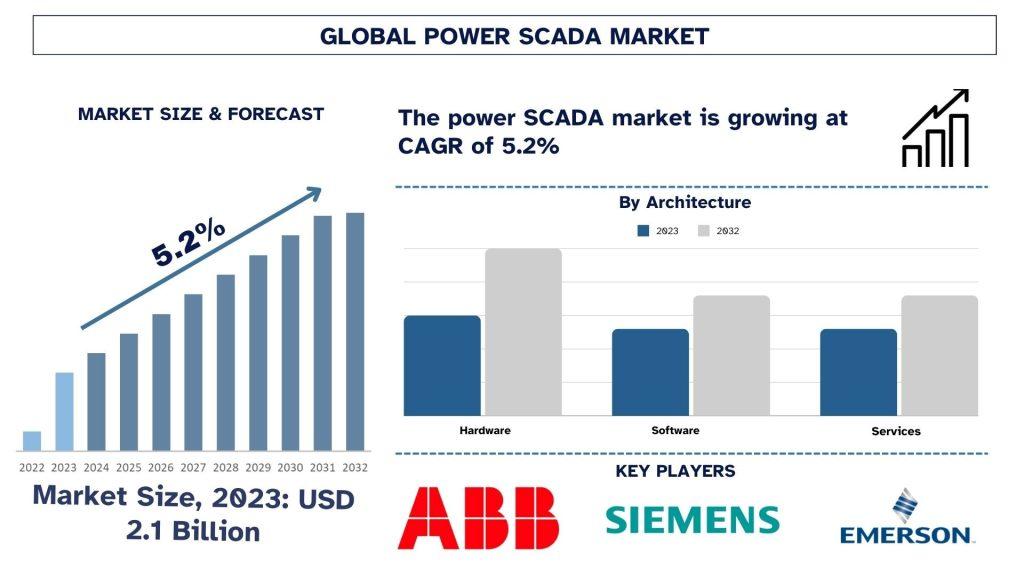

According to a new report by UnivDatos Market Insights, the Power SCADA Market was valued at approximately USD 2.1 Billion in 2023 and is expected to grow at a robust CAGR of around 5.2% during the forecast period (2024-2032). Currently, due to the advancement in technology, companies are always on the lookout for ways to automate and enhance operations as well as industrial procedures. Ever since the discovery of computers and the World Wide Web, machines have slowly started installing computing technologies into their structures. The emergence of these systems in the traditional existing structure can be considered as the start of a new period in the Industrial Revolution. As with most industries, power systems have developed to cater to the needs of investors, consumers, and operators in the last few decades. Enterprise resource planning solutions: the main impact on power systems describes that automation has been a result of the implementation of these solutions. Consequently, power systems started to utilize SCADA systems in the last part of the twentieth century. However, before discussing SCADA systems in detail, its history must be discussed.

Access sample report (including graphs, charts, and figures): https://univdatos.com/get-a-free-sample-form-php/?product_id=68085

SCADA Systems in Oil and Gas: Driving Innovation and Efficiency in the Digital Age

In the oil and gas industry, supervisory control and data acquisition Scada has emerged as a revolutionary concept that is revolutionizing operations across the value chain. Cutting across the upstream, middle, and downstream, this article provides a detailed analysis of such systems and relates the development and design of SCADA systems to their usage. SCADA systems in upstream invents real-time well monitoring, production optimization, and remote operation which increases the output and efficiency to a greater level. Midstream applications on the other hand aim at optimizing the use of pipelines with features such as maintenance prediction, improved leakage detection, and pipeline flow. Through automated quality assurance, energy consumption, and process control, SCADA systems can revolutionize the climate in refineries profoundly. Of course, some challenges come with system integration, and in the case of SCADA, these include problems encountered in data management, cybersecurity issues, and issues of integration with legacy systems. Besides, looking at new developments capable of enhancing the functionalities of SCADA, this study considers edge computing, digital twins, AI, machine learning integration, and 5G. Using SCADA, the oil and gas industry can be made efficient, safe, and innovative. The ensuing analysis of SCADA implementation lessons and impediments underlines that companies becoming integrated with the new technologies while also overcoming key implementation challenges will be best placed to thrive in the challenging, competitive, and complex energy marketplace of the future. Notably, this adoption has been especially prominent in regions with well-established oil and gas infrastructure such as North America and Europe; these two regions account for over 60% of the SCADA market in the industry.

Several significant themes have characterized the development of SCADA systems in the oil and gas industry:

Enhanced Integration: Modern SCADA systems are integrating with other business systems rapidly more and more, especially with advanced systems like Asset Performance Management (APM) and Enterprise Resource Planning (ERP). They are no longer the standalone solutions. Due to this integration, operations management is now a broader concept, as evidenced by the enhanced decision-making capacities revealed by 78% of the oil and gas industry players.

Better Cybersecurity: With the more advanced integration in computer networks, SCADA systems usher in cyber security concerns. Therefore, industry consumption of cybersecurity solutions related to SCADA systems has trended upward by 35% each year since 2018.

Cloud Adoption: As of 2021, 62% of oil and gas businesses implement cloud integration in their SCADA systems for their businesses up from 27% in 2016. This has suggested an increase in the trend of converting to cloud-based SCADA solutions.

The cumulative impact of these changes has been unprecedented improvements in the operational efficiency levels. Companies with complex SCADA systems, for example, experience roughly a 15 % reduction in unplanned downtime and a 20 % rise in asset usage. Also, the efficient use of the SCADA system has led to a reduction of the maintenance cost by 30% among some operators due to predictive maintenance.

Click here to view the Report Description & TOC https://univdatos.com/report/power-scada-market/

SCADA ARCHITECTURE: THE NERVOUS SYSTEM OF OIL AND GAS OPERATIONS

The nervous system of industrial operations is made up of a sophisticated network of interconnected components that make up modern SCADA systems in the oil and gas industry. Real-time monitoring, control, and optimization across many, frequently geographically scattered assets are made possible by this complex architecture.

· A case study of one of the leading players in the Eagle Ford Shale indicated that an enhanced SCADA system led to a productivity improvement of approximately 22% and a 35% reduction in Well downtime. The predictive analytical functions of the system allowed for preventive maintenance functions that further reduced cases of random breakdowns.

· This case study is an ideal example to understand how complex SCADA systems can transform the upstream operation. The operator implemented an end-to-end SCADA system with production enhancement algorithms accompanied by real-time well monitoring and teleoperation. The ability of the system to integrate data from one or more sources – surface instruments, downhole sensors, and previous production data was critical to the performance of the system.

· The aspect of the system that provided for maintenance based on predictions of when certain components would degrade had a major influence. It was also reported that the technology used the trends in the performance of equipment data to make estimations on possible equipment failures up to two weeks in advance. Therefore, it became possible to minimize production losses as well as to plan interventions by maintenance teams during planned downtime. In return, the unscheduled downtime was reduced from 12% to 4% enhancing overall production tremendously.

Conclusion

By presenting the details, it can be proposed that the SCADA system can be employed on a greater capacity in power systems to obtain higher performance and reliability along with life span. Equipment data monitoring and especially data acquisition can be very convenient and accurate if power systems are commissioned to SCADA. Today, electrical systems are very highly efficient and smart enough to oversee all the correlated activities and actions, and it would have not been possible without the aid of technology. Thus, the power sector needs to see the need and organize itself to meet the new technical changes.

Related Energy & Power Market Research Report

India Heat Transfer Fluids Market: Current Analysis and Forecast (2024-2032)

Gear Motors Market: Current Analysis and Forecast (2024-2032)

India Gas Insulated Switchgear Market: Current Analysis and Forecast (2024-2032)

Fuel Flexible Boiler Market: Current Analysis and Forecast (2024-2032)

Power Factor Correction Market: Current Analysis and Forecast (2024-2032)

Contact Us:

UnivDatos Market Insights

Email - contact@univdatos.com

Contact Number - +1 9782263411

Website - https://univdatos.com/

Linkedin- https://www.linkedin.com/company/univ-datos-market-insight/mycompany/