In today’s construction and design industries, materials that combine strength, durability, and aesthetic appeal are in high demand. PC hollow sheets, or polycarbonate hollow sheets, are among the most versatile options available, offering a unique balance of functionality and aesthetics. These sheets have revolutionized architecture and design, making them a preferred choice for roofing, partitions, signage, and more. In this Pulkit Plastic Products, we’ll explore the features, benefits, and applications of hollow polycarbonate sheets, highlighting why they have become indispensable in modern construction.

What Are Polycarbonate Hollow Sheets?

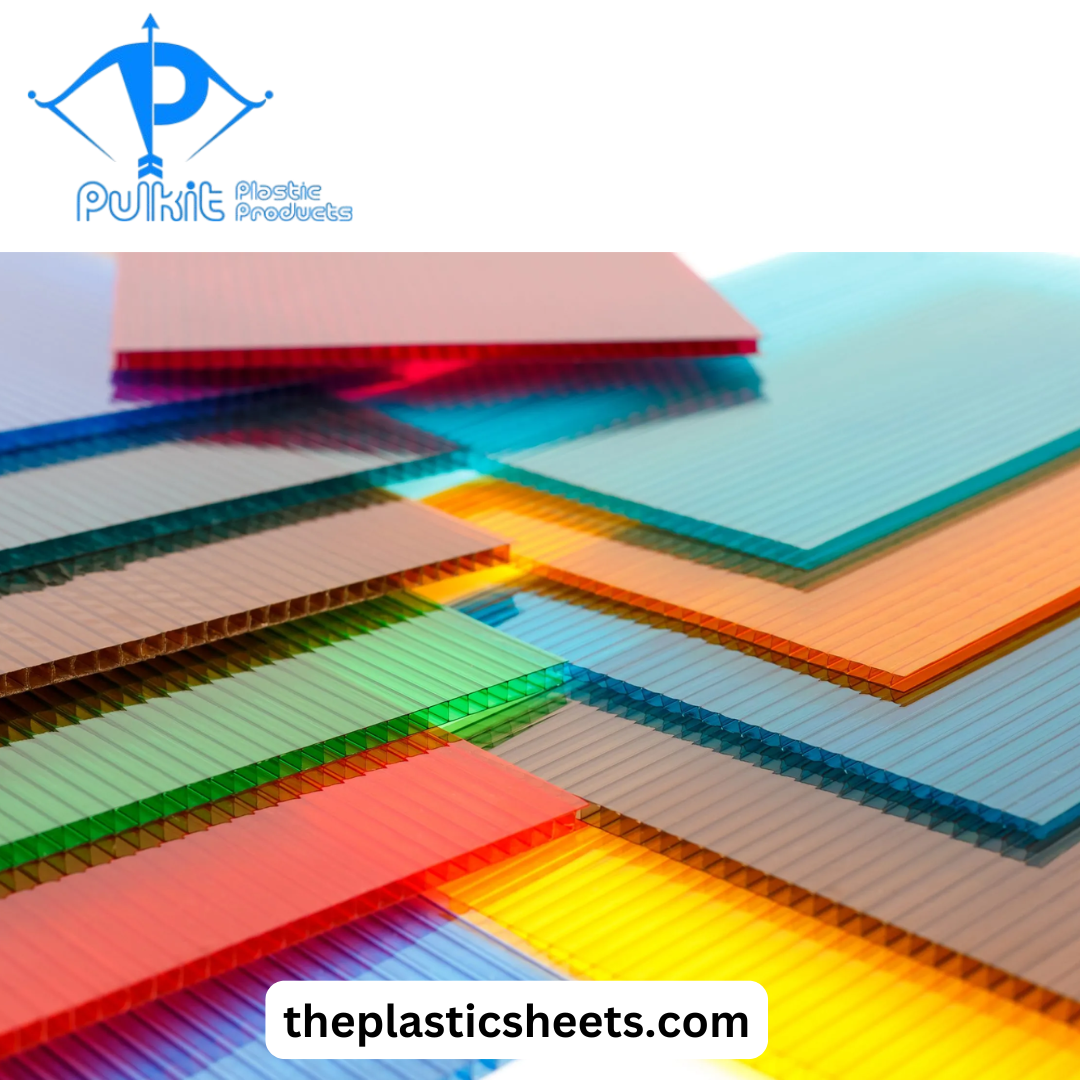

Polycarbonate hollow sheets, often referred to as hollow sheet polycarbonate, are lightweight, multi-layered sheets made from polycarbonate material. They feature a unique hollow structure, which gives them excellent thermal insulation and light diffusion properties. These sheets are available in various thicknesses, colors, and designs, making them highly adaptable for diverse applications.

The lightweight nature of these sheets doesn’t compromise their strength. Polycarbonate is an exceptionally durable material known for its impact resistance, up to 200 times stronger than glass. This strength, coupled with flexibility, makes polycarbonate hollow sheets a go-to material for both residential and commercial projects.

Key Features of PC Hollow Sheets

The Hollow polycarbonate sheets stand out due to their exceptional properties, which contribute to their widespread popularity:

-

High Impact Resistance

Polycarbonate hollow sheets are virtually unbreakable, providing a sturdy solution for areas prone to physical stress, such as sports arenas, parking lots, or industrial facilities. -

Lightweight

Despite their strength, these sheets are incredibly lightweight, which simplifies handling, transportation, and installation compared to traditional materials like glass or metal. -

UV Resistance

Many hollow sheet polycarbonate products come with UV protection layers, making them suitable for outdoor applications without the risk of discoloration or material degradation. -

Thermal Insulation

The hollow structure of the sheets offers excellent insulation, reducing heat transfer and energy consumption, particularly in climate-controlled environments. -

Optical Clarity and Light Diffusion

Polycarbonate sheets are known for their transparency and ability to diffuse natural light evenly, creating bright and welcoming spaces. -

Weather Resistance

These sheets can withstand extreme weather conditions, from heavy rains to snow and intense sunlight, without warping or cracking.

Applications of Hollow Polycarbonate Sheets

The adaptability of polycarbonate hollow sheets makes them suitable for a wide range of applications in various industries:

-

Roofing and Skylights

Their lightweight nature, transparency, and durability make them ideal for roofing applications, including skylights in homes, greenhouses, and commercial spaces. -

Partitions and Wall Panels

In offices and retail spaces, hollow sheet polycarbonate serves as a modern alternative to traditional partitions, providing both privacy and aesthetic appeal. -

Greenhouses

The thermal insulation and light diffusion properties of polycarbonate sheets create an ideal environment for plant growth, making them a preferred choice for greenhouses. -

Signage and Advertising Boards

With excellent printability and weather resistance, these sheets are often used in outdoor signage and advertising boards. -

Architectural Features

From canopies to facades, the sleek and modern appearance of hollow polycarbonate sheets enhances the visual appeal of contemporary architectural designs. -

Industrial Applications

In warehouses and factories, these sheets are used for protective barriers, roof coverings, and enclosures due to their impact resistance and durability.

Advantages of Using Hollow Polycarbonate Sheets

The benefits of Hollow polycarbonate sheets go beyond their physical properties, offering economic and environmental advantages as well:

-

Cost-Effective

Compared to traditional materials like glass, polycarbonate hollow sheets are more affordable while providing similar or superior benefits. -

Energy Efficiency

Their insulating properties reduce energy consumption for heating or cooling, making them a sustainable choice for eco-conscious projects. -

Versatility in Design

Available in various colors, finishes, and thicknesses, these sheets allow for creative freedom in design without compromising on functionality. -

Eco-Friendly

Polycarbonate sheets are recyclable, aligning with modern sustainability goals and reducing construction waste. -

Ease of Maintenance

These sheets are easy to clean and maintain, with a simple wipe-down restoring their shine and clarity.

Hollow Sheet Polycarbonate in Modern Architecture

Modern architecture emphasizes innovation, sustainability, and aesthetics—qualities that hollow polycarbonate sheets embody. Architects and designers favor these sheets for their ability to blend functionality with visual appeal.

-

Lightweight Roofing

In large-scale projects such as stadiums or airport terminals, lightweight roofing solutions are essential. Polycarbonate hollow sheets reduce structural load while maintaining durability. -

Sustainable Designs

The energy efficiency of hollow sheet polycarbonate supports sustainable building practices, contributing to green certifications like LEED. -

Enhanced Natural Lighting

By allowing natural light to flow through, these sheets minimize the need for artificial lighting, creating energy-efficient and inviting spaces. -

Innovative Facades

The sleek appearance of these sheets adds a futuristic touch to building facades, enhancing the overall aesthetics of modern structures.

Challenges and Considerations

While polycarbonate hollow sheets offer numerous advantages, certain challenges must be addressed to ensure optimal performance:

-

Scratching

Polycarbonate is more prone to scratches than glass. Using protective coatings or careful handling can mitigate this issue. -

Expansion and Contraction

These sheets may expand or contract with temperature changes. Proper installation techniques, such as allowing for thermal expansion, can prevent warping. -

Cost of High-Quality Sheets

While affordable overall, premium quality sheets with UV protection or specialized coatings can be costlier. However, the long-term benefits often justify the investment.

By understanding these challenges and adopting appropriate solutions, the full potential of hollow polycarbonate sheets can be realized in construction and design projects.

Conclusion

The Polycarbonate hollow sheets have transformed the construction landscape with their unmatched combination of strength, durability, and aesthetic versatility. Whether for roofing, partitions, or architectural elements, hollow polycarbonate sheets provide a cost-effective and sustainable solution for a wide range of applications. As innovations in materials science continue, the future of hollow sheet polycarbonate looks promising, offering even greater opportunities for creative and sustainable designs.

Incorporating these sheets into projects not only enhances functionality but also aligns with modern goals of efficiency and environmental responsibility. Their growing popularity underscores their importance as a building material that is both practical and forward-thinking.

Frequently Asked Questions

1. What is a hollow polycarbonate sheet, and how does it differ from solid polycarbonate?

A hollow polycarbonate sheet is a multi-layered sheet with a hollow core, offering better thermal insulation and light diffusion compared to solid polycarbonate sheets. Its lightweight structure makes it ideal for roofing and partitions.

2. Are hollow sheet polycarbonate options suitable for outdoor use?

Yes, many hollow polycarbonate sheets come with UV protection, making them highly durable for outdoor applications like roofing, greenhouses, and facades.

3. How do I maintain and clean hollow polycarbonate sheets?

Hollow polycarbonate sheets are low maintenance. Use a soft cloth and mild soap solution to clean them. Avoid abrasive cleaners or sharp tools that may scratch the surface.

4. Can polycarbonate hollow sheets be recycled?

Yes, polycarbonate hollow sheets are recyclable. Many manufacturers use eco-friendly practices, allowing these sheets to be repurposed into new materials after their lifecycle ends.