A simple explanation of what needs to be done is to use gas to blow off any residues that are still on the mold. This can be done as part of the cleaning process. This explanation would be the one that would be the simplest to grasp. This step is performed following the use of the mold in the previous step. The smoothness of the mold will suffer if there is any residue left over from the manufacturing process. A flash will be produced, and the surface of the mold that separates will be crushed as it breaks apart. This will occur as the mold separates. Flash will be produced as a direct consequence of this action.

A simple explanation of what needs to be done is to use gas to blow off any residues that are still on the mold. This can be done as part of the cleaning process. This explanation would be the one that would be the simplest to grasp. This step is performed following the use of the mold in the previous step. The smoothness of the mold will suffer if there is any residue left over from the manufacturing process. A flash will be produced, and the surface of the mold that separates will be crushed as it breaks apart. This will occur as the mold separates. Flash will be produced as a direct consequence of this action.

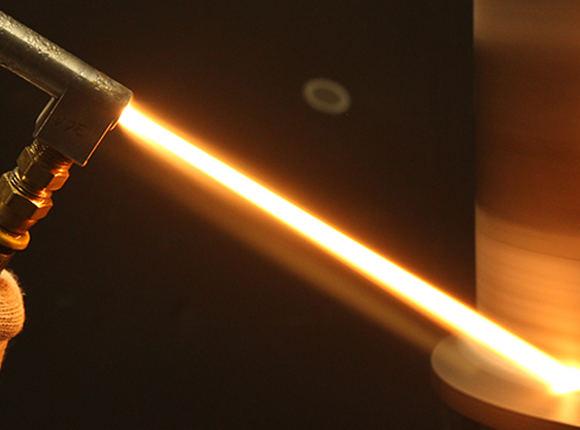

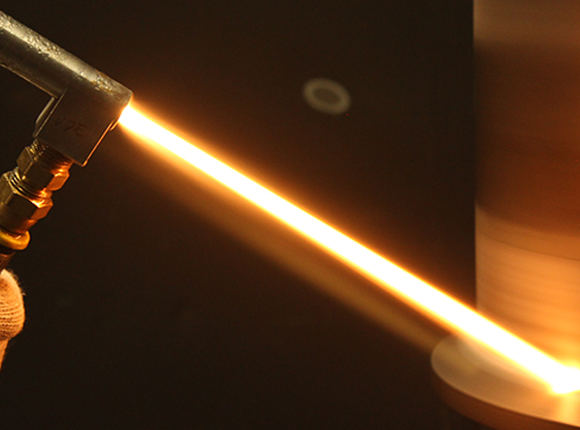

Indirectly bringing the temperature of the mold into equilibrium can be accomplished in a number of ways, one of which is by spraying the mold with aqueous solutions, which has the dual effect of both lowering and maintaining the temperature of the mold.This is a task that requires caution and affords opportunities for discovery, and it should be approached as though it were both of these things because that is how it should be done.

The castings that are produced by a mold have a significant relationship with the temperature at which the mold was stored.It is essential to make any necessary adjustments to the position of the mold as well as the temperature control based on the specifics of each mold. These adjustments may include moving the mold to a different location or China die casting mold increasing or decreasing the temperature.In the end, it will be essential to acquire these parameters along with a great deal of experience gained over the course of many years through the process of carrying out trials at the actual location.

If the obtained parameters are not subjected to additional testing before the temperature changes, then there will be new issues after the mold trial has been successful but after production has begun. If this step is skipped, new problems will appear after the mold trial has been successfully completed, but after production has already begun. This will be the case even if the step is not skipped. At this point, the amount of time it takes for the mold to cool down after it has been heated is the most important factor that plays a part in determining how long it will take us to spray. While the mold is being evaluated, while production is being initiated, and while the level of production is being brought up to a consistent level, it is subjected to a wide range of temperatures. Because of this, the slider, the ejector pin, and the core will not produce any dry friction or nap even if the temperature in the chamber were to rise. If the air pressure is low and the water pressure is high, there will be a significant amount of water in the mist due to the pressure difference between the two, which will cause there to be more water in the mist.

It is of the utmost importance that the amount of paint to water ratio adhere to the parameters of a predetermined, acceptable range. The limits of this range have been determined in advance, along with its other parameters. In the event that the concentration is not high enough, the film is going to be a fantastic option. It is absolutely necessary to increase the dilution factor whenever one is working with things that are straightforward and uncomplicated. One is able to determine the optimal dilution factor as well as the appropriate volume of spray to use if they carry out a series of experiments with the intention of achieving this goal.

If the distance is too great, on the other hand, the paint mist will condense into larger droplets rather than remaining die casting mould in the state of a finer mist. The formation of an isolation film that is sufficiently thick can be completed in as little as one or two seconds, which is all that is required for the injection process. This is enough on its own. It is imperative that special attention be paid to the areas of the mold that cannot be sprayed because the shape of the mold itself is complicated. This will ensure that the quality of the product remains consistent throughout the entirety of the production process at the same high level. The continued impact of molten aluminum will cause the temperature of these parts to rise, which may result in flying materials or mold sticking. This is a risky situation. This will occur as a result of the melting of the aluminum. It has been discovered that a sizeable portion of the flashes are capable of sticking to the mold. As a direct consequence of that, this circumstance materialized.