The ceiling tiles market, integral to both residential and commercial construction, is growing steadily due to factors such as urbanization, aesthetic demand, and technological advancements. However, like all markets, it faces its share of challenges. These challenges range from fluctuating raw material costs to the increasing demand for sustainability, and competition among manufacturers. In this article, we will examine the key challenges faced by the ceiling tiles market and how industry stakeholders are navigating these issues.

1. Fluctuating Raw Material Costs

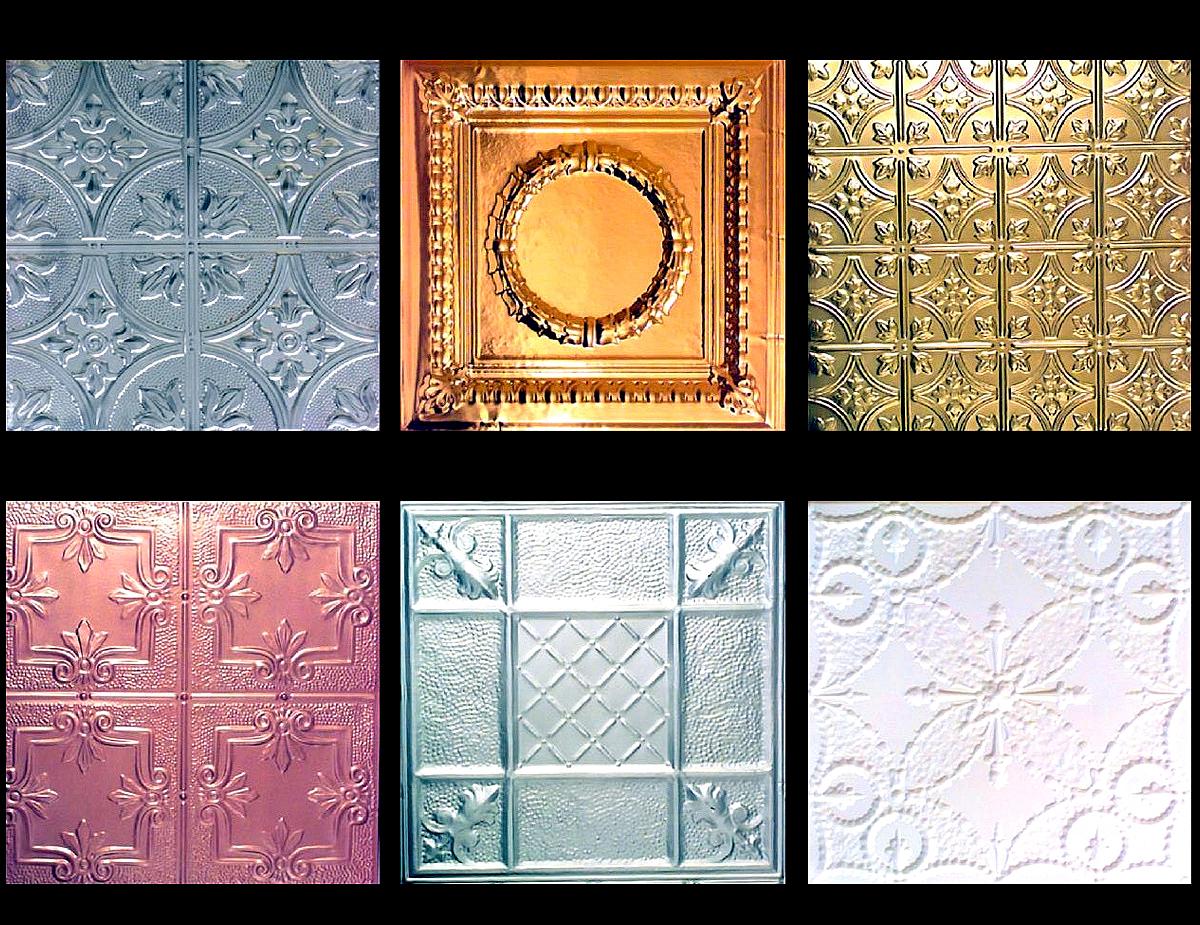

One of the biggest challenges for ceiling tile manufacturers is the fluctuation in raw material prices. Ceiling tiles are made from a variety of materials, including mineral fibers, gypsum, metal, and PVC, each with its own supply chain and cost dynamics. The prices of materials like gypsum and mineral fibers can fluctuate based on global supply and demand, transportation costs, and geopolitical factors.

For example, the cost of raw materials for ceiling tiles can increase due to disruptions in supply chains or scarcity of certain materials. Manufacturers face the pressure of maintaining product prices that remain competitive while dealing with rising raw material costs. In order to manage this, many companies are looking for alternative, cost-effective materials or exploring vertical integration strategies to secure their supply chains.

2. Price Sensitivity in Emerging Markets

While demand for ceiling tiles is growing worldwide, the price sensitivity in emerging markets poses a challenge. Many developing regions, particularly in Asia Pacific, Latin America, and Africa, face cost constraints in construction and renovation projects. As a result, builders in these markets are often focused on budget-friendly solutions, opting for less expensive ceiling tile options.

In such price-sensitive regions, manufacturers face the challenge of balancing cost-effective production with maintaining quality and performance standards. Offering affordable yet high-quality ceiling tiles while ensuring durability and functionality becomes a critical task. To address this challenge, manufacturers are introducing innovative low-cost alternatives that still meet basic acoustic, aesthetic, and fire resistance standards.

3. Environmental Sustainability Pressure

Environmental concerns and the increasing focus on sustainable building materials are driving a significant change in the ceiling tiles market. Governments, organizations, and consumers alike are demanding eco-friendly products that adhere to environmental standards and certifications, such as LEED (Leadership in Energy and Environmental Design).

Ceiling tiles, traditionally made from materials like mineral fiber or PVC, can have a substantial environmental impact, especially in terms of raw material extraction and manufacturing processes. Meeting sustainability demands requires manufacturers to focus on using recycled or recyclable materials, reducing waste during production, and ensuring that the end product does not contribute to environmental degradation.

Moreover, with growing pressure to cut down on carbon emissions, the ceiling tile industry must adopt more sustainable practices and improve energy efficiency in their products. This transition can be costly for manufacturers, who must invest in research and development, new technologies, and sustainable raw materials, while also keeping their products competitive in a price-sensitive market.

4. Technological Innovation and Smart Ceiling Tiles

As the construction industry embraces digitalization and smart technologies, the demand for more technologically advanced products is increasing. In the ceiling tiles market, innovations such as smart ceiling tiles, which integrate lighting, air sensors, and temperature control, are becoming more prevalent. While these innovations offer immense potential, they also introduce significant challenges.

The manufacturing of smart ceiling tiles involves complex technology, requiring high levels of expertise and additional investment in research and development. Furthermore, manufacturers must collaborate with tech companies to integrate IoT (Internet of Things) capabilities into their ceiling tiles, a process that requires significant time and cost. Smart ceiling tiles also require a higher price point, which may limit their adoption in cost-sensitive markets.

Another challenge is the limited standardization of smart technologies in ceiling tiles, creating barriers to widespread acceptance. The lack of uniformity in terms of installation and compatibility with other building systems may also hinder growth in this segment.

5. Intense Competition

The ceiling tiles market is highly competitive, with numerous regional and global players vying for market share. Manufacturers need to differentiate themselves by offering unique product features, customization options, and superior quality. However, with many players in the market, distinguishing one’s product can be challenging.

Additionally, the growing number of local manufacturers in emerging markets poses a threat to established global players. These local manufacturers often produce low-cost ceiling tiles, which appeal to price-sensitive customers, putting pressure on international brands to lower their prices while maintaining quality.

To stay competitive, manufacturers are focusing on innovation, brand loyalty, and customer service. Many companies are investing in R&D to introduce new designs, advanced materials, and technologies that address specific customer needs, such as soundproofing, fire resistance, and sustainability. Offering customization options and superior product performance also helps brands distinguish themselves in a crowded market.

6. Regulatory Challenges

The ceiling tiles market is subject to a variety of building codes, regulations, and standards that govern aspects such as fire resistance, noise control, and air quality. Manufacturers need to stay updated with these regulations to ensure that their products comply with local, regional, and international standards.

In some regions, regulatory requirements for ceiling tiles may differ, leading to challenges in producing products that meet varying standards. This is particularly true for global manufacturers operating in multiple markets, where compliance with different regulations can increase production costs and complexity. Adapting to changing regulations, particularly regarding environmental sustainability and material safety, requires manufacturers to be agile and proactive in adjusting their product lines.

7. Supply Chain Disruptions

Global supply chains have been under pressure in recent years, from disruptions caused by the COVID-19 pandemic to geopolitical tensions, and natural disasters. These disruptions can affect the availability of raw materials, increase lead times, and inflate costs. For ceiling tile manufacturers, supply chain challenges can hinder production schedules and impact their ability to meet demand in a timely manner.

To mitigate the risks associated with supply chain disruptions, some manufacturers are looking at local sourcing strategies and diversifying their supplier base. While these solutions may not eliminate the issue entirely, they can reduce the dependency on a single source and minimize the impact of global disruptions.

Conclusion

The ceiling tiles market is growing, but it faces a range of challenges that manufacturers must address to remain competitive and meet the evolving needs of consumers. From raw material price volatility and price sensitivity in emerging markets to sustainability pressures and intense competition, the industry must adapt to these issues while pursuing innovation and growth. By embracing sustainability, focusing on technological innovations, and improving supply chain resilience, the ceiling tiles market can overcome these challenges and continue to thrive in the coming years.