The conductive foam market has undergone significant evolution over the past few decades, driven by advancements in technology, increasing demand from electronics, automotive, and telecommunications industries, and a growing focus on electrostatic discharge (ESD) protection and electromagnetic interference (EMI) shielding. This market’s evolution can be attributed to continuous innovations in materials, manufacturing processes, and growing applications across diverse sectors. Let’s explore how the conductive foam market has evolved and the factors that are driving its growth today.

Early Beginnings and Market Development

The roots of conductive foam can be traced back to the mid-20th century, as the need to protect sensitive electronic components from electrostatic discharge (ESD) and EMI became more apparent. ESD can cause significant damage to electronic devices, rendering them non-functional or degrading their performance. As electronic devices became more compact and complex, the need for reliable and efficient ESD protection solutions led to the development of conductive materials such as conductive foam.

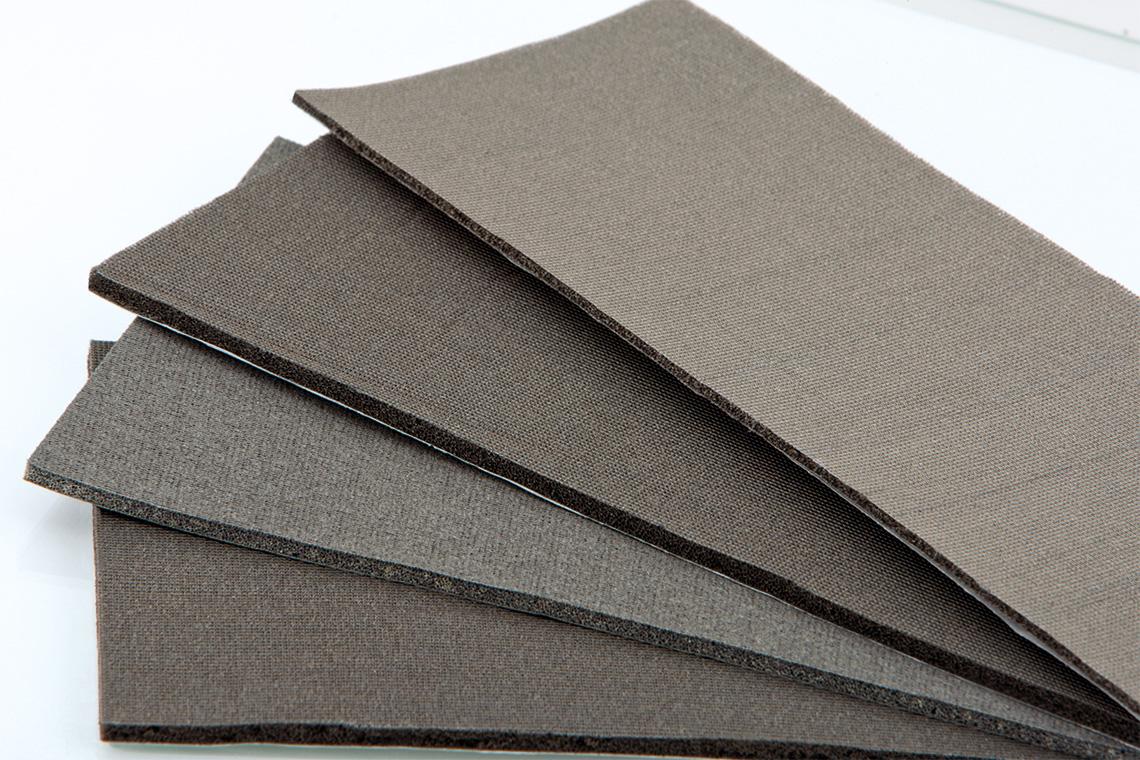

Initially, conductive foam was primarily used in the electronics industry, where it served as a protective material for semiconductor devices, circuit boards, and other delicate components. This foam typically combined the flexibility of traditional foam with conductive materials such as carbon or metal-based particles to allow the dissipation of static electricity. The early evolution of conductive foam was marked by a focus on improving the material's conductivity while maintaining its flexibility and cushioning properties.

Technological Advancements and Material Innovation

As technology continued to advance in the late 20th and early 21st centuries, the demand for conductive foam grew. The electronics sector, in particular, required more advanced solutions to protect ever-smaller and more delicate components. This increased demand pushed manufacturers to innovate and enhance the conductive foam's properties.

The most significant innovation came with the development of conductive foams that used carbon-based materials, such as carbon black, to improve conductivity. These foams offered more consistent performance and greater cost-effectiveness compared to traditional metal-based foams. As manufacturing techniques improved, conductive foams became easier to produce, more durable, and more versatile, which helped meet the growing demand across different sectors.

Further innovations in material science also led to the development of high-performance conductive foams that could withstand harsher environments. For example, some conductive foams were engineered to be more heat-resistant, resistant to chemicals, or capable of providing shielding from electromagnetic interference (EMI) in addition to ESD protection. These innovations expanded the use of conductive foam beyond just electronic packaging to a broader array of applications, including automotive, telecommunications, and industrial sectors.

Expansion of Applications Across Industries

Over time, the conductive foam market has expanded beyond the traditional electronics industry. The automotive sector, for instance, has increasingly adopted conductive foam in electric vehicles (EVs) for EMI shielding and ESD protection. As the use of electric and autonomous vehicles has grown, the need for protection from electromagnetic interference has risen sharply. Conductive foam helps reduce electromagnetic radiation, preventing vehicle systems from being affected by signals from other components or external sources.

In the telecommunications industry, conductive foam is utilized in various applications, such as protecting sensitive components in telecommunications devices, mobile phones, and networking equipment. With the rise of 5G networks and the increasing complexity of telecom systems, the demand for high-performance conductive foams has soared.

Additionally, the healthcare industry has also started to adopt conductive foam in applications like medical device packaging and electronic equipment used in healthcare facilities, where ensuring the safety and functionality of sensitive equipment is paramount.

Environmental Considerations and Sustainability

As environmental concerns gain traction, the conductive foam market is witnessing a shift toward more sustainable practices. Traditional conductive foams were often made from non-renewable petroleum-based materials, which raised concerns about their environmental impact. In response, manufacturers are increasingly exploring bio-based and recyclable alternatives, using materials such as plant-based plastics or recycled polymers in foam production.

This shift to sustainability is becoming essential as manufacturers face increasing pressure from regulators, environmental groups, and consumers to adopt greener practices. Sustainable production methods, such as using less energy in manufacturing and reducing waste, are increasingly being integrated into the production process, which enhances the environmental credentials of the conductive foam market.

The Future of Conductive Foam

Looking ahead, the future of the conductive foam market is bright. The market is expected to continue evolving as new applications and industries emerge. With the rise of advanced electronics, the proliferation of electric vehicles, and the ongoing development of new technologies, the demand for conductive foam will only grow.

As the need for more complex and precise electronic components rises, so does the demand for high-quality, versatile conductive foams. Innovations in material science, sustainability efforts, and the expansion of application sectors will continue to shape the future trajectory of this market.

Moreover, the integration of smart technologies, such as sensors, artificial intelligence (AI), and Internet of Things (IoT) devices, will further accelerate the demand for conductive foam. These technologies require materials that can protect electronic components from the effects of electrostatic discharge, EMI, and environmental factors—making conductive foam an essential component in future technological advancements.

Conclusion

The conductive foam market has evolved significantly from its early days of providing basic ESD protection to becoming a critical component across various industries. Technological advancements, material innovations, and expanded applications have all played key roles in this evolution. As industries continue to push for higher performance and more sustainable solutions, the conductive foam market will likely continue to innovate and grow, with a focus on meeting the demands of emerging technologies and ensuring environmental sustainability.