Thin-Film Encapsulation (TFE) Market Segmentation: Analyzing the Impact of Different Barrier Coating Materials on Market Performance

The Thin-Film Encapsulation (TFE) Market is experiencing rapid growth, fueled by the increasing demand for advanced, durable, and energy-efficient electronic devices. Central to the performance and reliability of thin-film technologies—such as organic light-emitting diodes (OLEDs), flexible displays, solar cells, and wearable electronics—is the choice of barrier coating materials used in encapsulation. These materials play a crucial role in protecting sensitive components from moisture, oxygen, and other environmental factors that can degrade device performance. In this context, the segmentation of the TFE market based on different barrier coating materials is essential for understanding their impact on the overall market performance and the future potential of various applications.

Polymer-Based Barrier Coatings

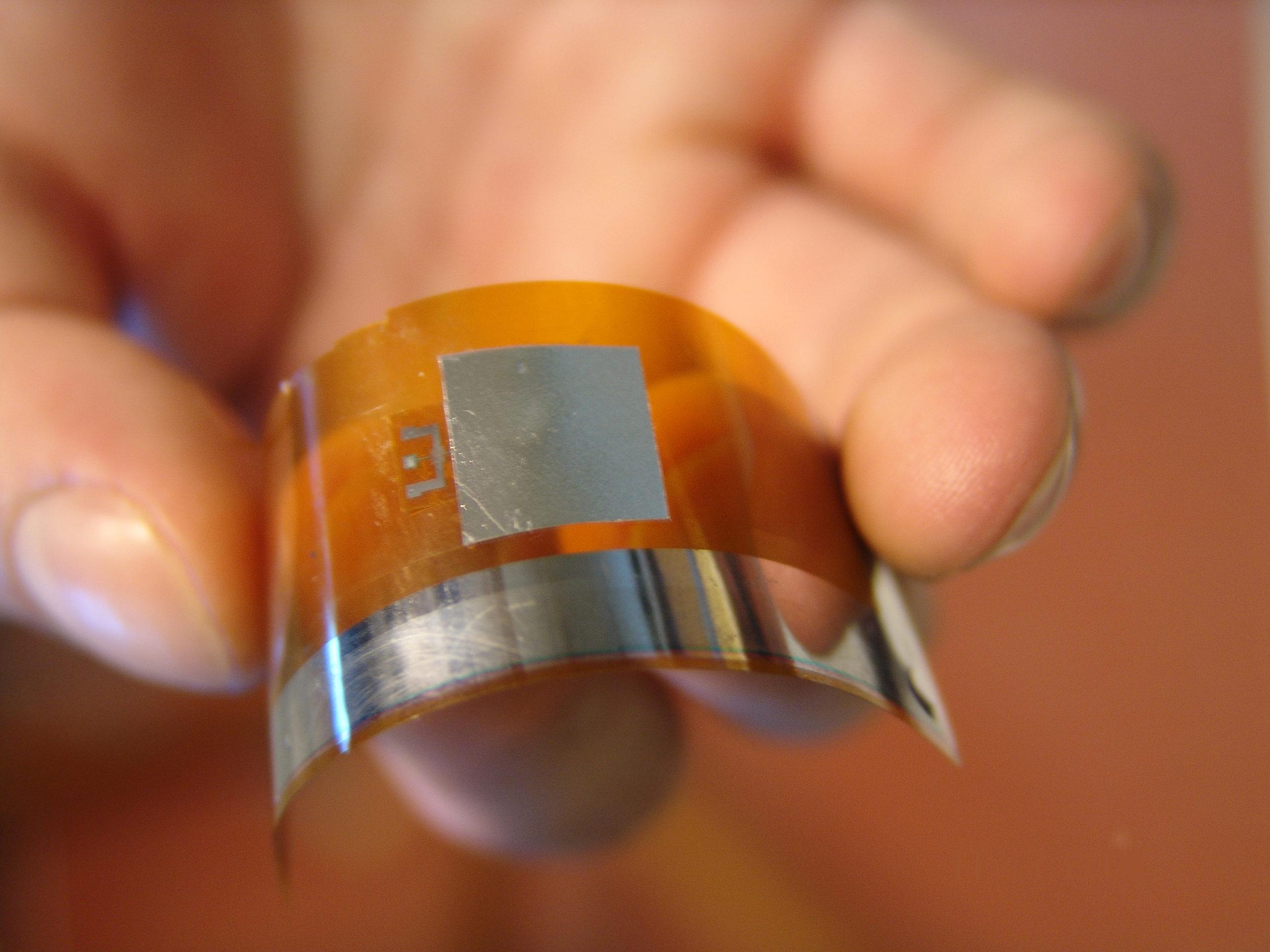

Polymer-based barrier materials, including both organic and inorganic-organic hybrid polymers, are widely used in thin-film encapsulation due to their flexibility, lightweight nature, and ease of processing. These materials are ideal for flexible electronics, such as OLEDs and organic solar cells, where maintaining both performance and flexibility is key. Polymer barriers can be easily integrated into roll-to-roll (R2R) manufacturing processes, making them cost-effective for large-scale production. Innovations in barrier polymers, such as those developed with silica nanoparticles, have improved their moisture and oxygen resistance, enabling longer device lifespans and more robust performance. As a result, the demand for polymer-based coatings is expected to grow rapidly in the flexible and wearable electronics market.

Inorganic Barrier Materials

Inorganic materials, including glass, silicon oxide (SiO₂), and aluminum oxide (Al₂O₃), are traditionally used for encapsulating rigid devices like flat-panel displays and conventional solar cells. These materials offer exceptional protection against environmental degradation, providing excellent barriers to moisture and oxygen. However, their application in flexible electronics is limited due to their rigid nature and susceptibility to cracking under stress. Advances in thin, flexible inorganic coatings, such as atomic layer deposition (ALD) films, are addressing this limitation, providing high-performance encapsulation solutions for flexible electronics. The inorganic segment of the TFE market is expected to remain dominant in applications that require highly durable and long-lasting barriers, including certain types of solar cells and high-end displays.

Hybrid Barrier Materials

Hybrid materials, combining both organic and inorganic components, represent an emerging trend in the TFE market. These materials combine the flexibility and ease of processing of polymers with the durability and high barrier properties of inorganic substances. Hybrid coatings offer a balanced solution, providing high moisture and oxygen resistance while maintaining the flexibility required for wearable and foldable electronics. This segment is particularly promising for applications in flexible solar panels, OLEDs, and other organic electronics, where a combination of performance, flexibility, and durability is critical. The growth of hybrid materials in the TFE market is expected to be fueled by advancements in nanomaterials and deposition technologies.

Market Impact and Performance

The choice of barrier material significantly impacts the performance, cost-effectiveness, and scalability of thin-film technologies. Polymer-based materials provide cost advantages and are widely used in high-volume, low-cost applications like flexible displays and wearables. Inorganic materials are ideal for high-performance applications that demand superior environmental protection, such as traditional solar panels and rigid displays. Hybrid materials represent a balance between these two, driving innovation in flexible and foldable electronics. As the TFE market continues to evolve, advancements in material science, including improvements in barrier properties, flexibility, and manufacturing processes, will further enhance the market’s growth prospects.

In conclusion, the Thin-Film Encapsulation (TFE) Market is shaped by the impact of different barrier coating materials, each of which plays a pivotal role in the performance of various electronic devices. Polymer, inorganic, and hybrid materials each have unique advantages, with ongoing innovations helping to address the challenges of flexibility, durability, and environmental protection. As the demand for flexible, energy-efficient, and long-lasting devices grows, the TFE market will continue to evolve, driven by advancements in barrier material technologies. Understanding the segmentation and material choices will be critical for stakeholders to navigate and capitalize on the expanding opportunities in this dynamic market.

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Juegos

- Gardening

- Health

- Home

- Literature

- Music

- Networking

- Other

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness