Is 6061 aluminum plate suitable as a building material?

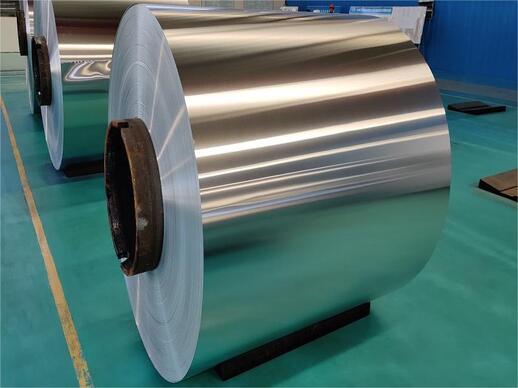

Introduction of 6061 aluminum sheet

Aluminum 6061 has excellent processing performance, good corrosion resistance, high toughness, no deformation after processing, easy color film, and excellent oxidation effect. It belongs to Al-Mg-Si alloy, medium strength, good plasticity and excellent corrosion resistance.

Yes, 6061 aluminum sheet has become a building material suitable for various applications due to its versatile properties.

Reasons why 6061 aluminum sheet is suitable for construction

Material composition and characteristics

6061 aluminum is part of the 6000 series of aluminum alloys, which are known for their good mechanical properties and corrosion resistance. The alloy is mainly composed of the following components:

Aluminum (Al): basic element

Magnesium (Mg): 0.8% to 1.2%

Silicon (Si): 0.4% to 0.8%

Other elements include trace amounts of chromium, copper, iron and zinc.

6061 aluminum sheet key features

- Density: 2.7 g/cm³ (lightweight compared to steel)

- Tensile strength: typically 290 MPa (42,000 psi) in T6 temper

- Yield strength: typically 240 MPa (35,000 psi) in T6 temper

- Hardness (Brinell): about 95 HB

- Thermal conductivity: 167 W/m·K

- Melting point: about 580-650°C (1076-1202°F)

Mechanical strength

6061 aluminum is known for its good strength-to-weight ratio, especially in the T6 temper. It strikes a balance between strength and ductility, allowing it to withstand large loads while remaining relatively easy to process. This makes it ideal for structural components where high strength is a must but excess weight can be a disadvantage.

Corrosion resistance

The presence of magnesium and silicon enhances the alloy's resistance to atmospheric and general corrosion. This property is critical for building materials exposed to outdoor environments, such as:

-Roofing systems

-Building facades

-Bridges and sidewalks

Its corrosion resistance also reduces maintenance requirements, making it cost-effective in the long term.

Machinability and processability

6061 aluminum is highly machinable, making it easy to cut, drill, mill, or shape. It can be welded using common welding methods such as MIG and TIG welding, which is beneficial for manufacturing custom parts or complex structures. In addition, it can be treated with a variety of surface treatments, including anodizing and powder coating, which can further enhance its appearance and durability.

Lightweight and highly ductile

6061 aluminum is lightweight (about 1/3 the weight of steel), so it has advantages in applications where weight reduction is required, such as:

- Curtain walls

- Window frames

- Structural frames of skyscrapers

Ductility ensures that it can be stretched or formed without breaking, providing a variety of design options.

Thermal and Electrical Conductivity

6061 aluminum also has good thermal conductivity, making it suitable for heat exchangers or as a component of systems that need to dissipate heat efficiently, such as cooling systems and roofs that help reduce heat buildup.

Typical Applications of 6061 in Construction

The alloy's combination of strength, weight, and corrosion resistance make it suitable for a variety of building and construction applications, including:

- Structural beams and columns: Ideal for lightweight structural support.

- Stairs and ladders: Its light weight and corrosion resistance make it ideal for durable stair components.

- Cladding and paneling: Provides aesthetics and excellent weather resistance.

- Platforms and walkways: When treated or textured, it provides a durable and non-slip surface.

6061 Limitations and Considerations

While 6061 aluminum sheet has a wide range of uses, there are a few things to be aware of:

- Lower yield strength than steel: While high strength for aluminum, the yield strength is not as high as many steels. Therefore, in applications where extreme strength is required, it may need to be reinforced or replaced with a stronger alloy such as 7075 aluminum.

- Welding Issues: While 6061 is weldable, it may lose some strength in the heat-affected zone after welding, requiring post-weld heat treatment to restore strength.

- Potential for Galvanic Corrosion: If used with other metals such as steel or copper, it may be subject to galvanic corrosion unless appropriate insulation is used.

6061 aluminum sheet is an excellent choice of building material in scenarios that require a balance between strength, weight, corrosion resistance, and machinability. Its versatility makes it a top choice for modern construction and structural engineering, helping to achieve lightweight, durable, and cost-effective building solutions.

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Jogos

- Gardening

- Health

- Início

- Literature

- Music

- Networking

- Outro

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness