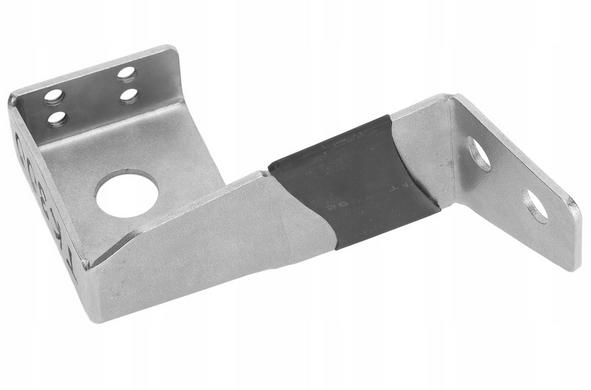

A sheet metal stamping die, also referred to as a tool or mold in the metalworking industry, plays a crucial role in shaping and forming sheet metal into precise configurations. In this article, we delve into the process of designing, preparing materials, constructing, and testing a sheet metal stamping die.

Designing the Stamping Die:

Before embarking on the manufacturing process, understanding the sheet metal part to be created is paramount. This involves comprehending its size, thickness, desired shape, and specific attributes.

Once the sheet metal part is understood, a design concept is formulated. This concept encompasses the overall layout, structure of the die, selection of punches, dies, and other essential components.

Choosing the appropriate material for the die is critical for its durability under high pressures and strains. Common materials include tool steel, carbide, and hardened steel.

Designing the structure and components of the die follows the established concept. Determining the size, shape, and arrangement of punches, dies, and blank holders is crucial at this stage.

Creating a die layout is the next step, defining the arrangement of components within the die, operational sequence, and required clearances between components.

Selecting Material and Preparing for Stamping:

Selecting the right sheet metal is essential for quality stamped parts. The metal's quality, constant thickness, and suitability for the intended application are key considerations.

Preparing the sheet metal involves cleaning it thoroughly to remove any debris and flattening it to ensure a smooth surface.

Cutting the sheet metal to the required size is done using various cutting equipment such as shears, plasma cutters, or laser cutters.

Cleaning the sheet metal again after cutting eliminates sharp edges or burrs, ensuring proper fit within the stamping die.

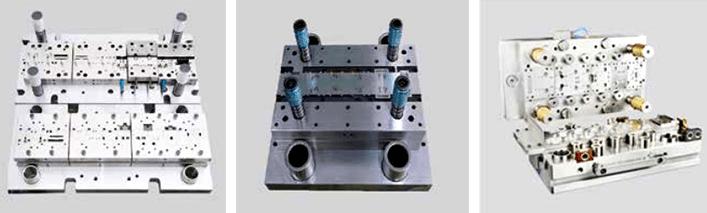

Making the Stamping Die:

Machining the die components to precise specifications is done using CNC machining techniques.

Heat treating the machined components strengthens them for longevity by heating them to high temperatures and rapidly cooling them.

Assembling the die involves integrating machined and heat-treated components using bolts and fasteners.

Testing and Troubleshooting:

Initial testing involves running sample stampings to ensure accurate and consistent results.

Troubleshooting is necessary if any issues arise, involving thorough inspection and adjustments to components or settings.

Fine-tuning the die may be required to optimize the metal stamping process based on troubleshooting results.

Re-testing after fine-tuning confirms improvements and ensures the die meets required standards.

In summary, following these steps meticulously ensures the creation of a high-quality sheet metal stamping die capable of producing precise and consistent stamped parts for various applications, including automotive, household appliances, and electronics manufacturing.