The cold forging machine market is experiencing robust growth, driven by a combination of technological advancements, rising demand across various industries, and a global focus on sustainability. As manufacturers seek more efficient and cost-effective production methods, the adoption of cold forging technology is rapidly increasing. This article explores the key factors fueling the expansion of the cold forging machine market on a global scale.

Understanding Cold Forging

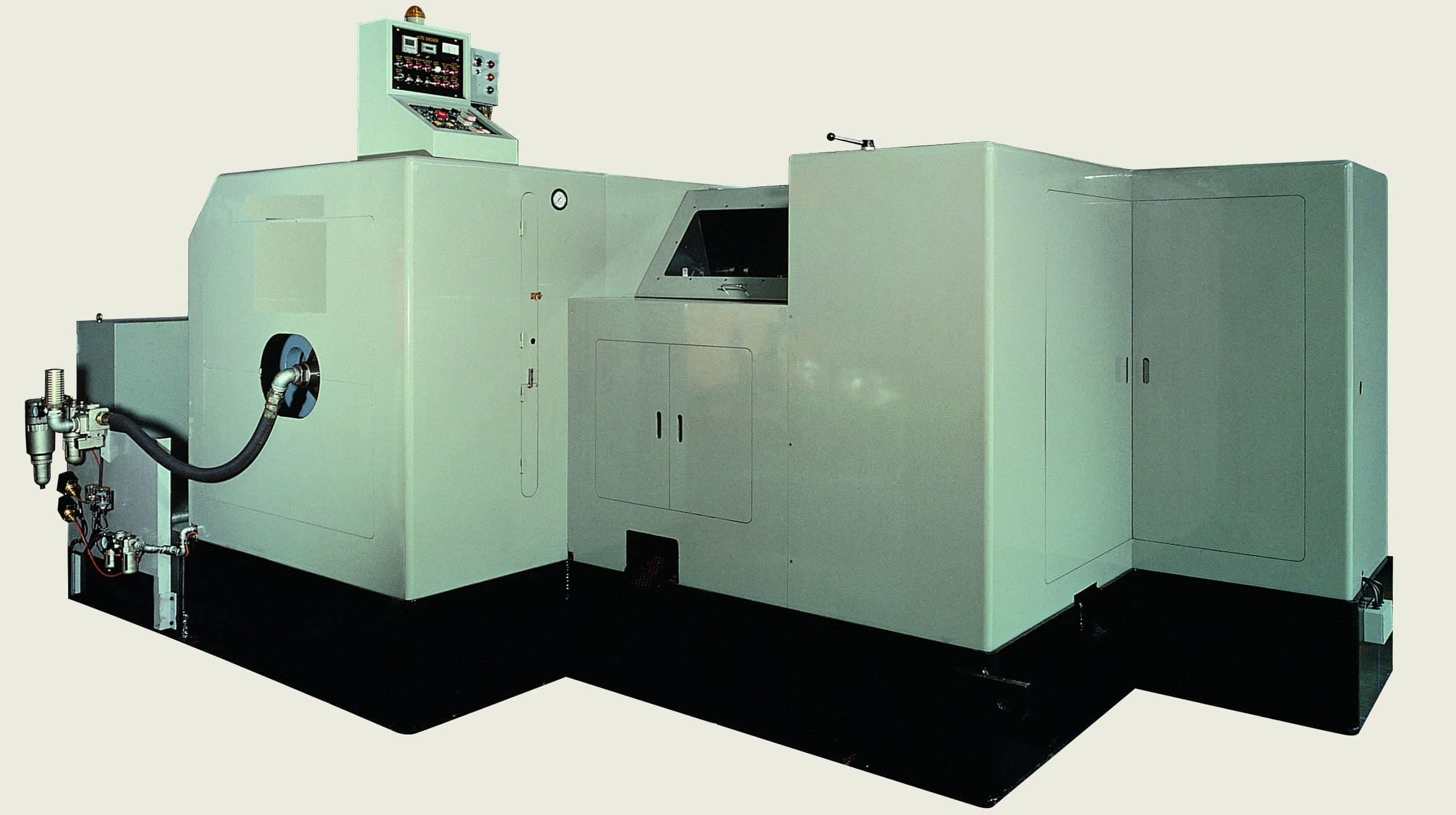

Cold forging is a metal forming process that shapes materials at room temperature, resulting in components with enhanced mechanical properties and superior surface finishes. This method is particularly valuable in high-volume production settings, making it popular in industries such as automotive, aerospace, electronics, and industrial machinery.

Key Factors Driving Market Growth

1. Technological Advancements

Continuous innovations in cold forging technology are a primary driver of market growth. The integration of automation, robotics, and smart manufacturing solutions enhances production efficiency and accuracy. Advanced cold forging machines equipped with IoT and AI capabilities allow for real-time monitoring and adjustments, significantly reducing downtime and waste.

2. Increased Demand for Lightweight Components

As industries like automotive and aerospace shift towards lightweight materials to improve fuel efficiency and performance, the demand for cold forging machines is rising. Cold forging is well-suited for processing lightweight materials such as aluminum and titanium, which are increasingly used in manufacturing components for these sectors.

3. Focus on Sustainability

Environmental concerns are driving manufacturers to adopt sustainable practices. Cold forging processes produce less waste and require less energy compared to traditional machining methods. This efficiency aligns with global sustainability initiatives, making cold forging an attractive option for manufacturers looking to reduce their environmental impact.

4. Customization and Flexibility

The need for customized solutions is becoming increasingly important across various industries. Manufacturers are seeking cold forging machines that can produce a wide range of components with varying specifications. The ability to quickly adapt to changing production requirements is essential for maintaining competitiveness, driving demand for flexible cold forging technologies.

5. Emerging Markets and Industrialization

Rapid industrialization in emerging markets, particularly in Asia-Pacific and Latin America, is contributing to the growth of the cold forging machine market. As these regions modernize their manufacturing capabilities, the demand for efficient production methods like cold forging is expected to rise significantly. Investment in infrastructure and manufacturing facilities in these markets presents substantial opportunities for cold forging machine manufacturers.

6. Growth of the Automotive Sector

The automotive industry is a significant driver of cold forging demand. With the increasing production of electric vehicles (EVs) and a shift towards more fuel-efficient designs, there is a growing need for high-quality, lightweight components. Cold forging meets these requirements effectively, leading to an uptick in investments in this technology by automotive manufacturers.

7. Expansion of the Aerospace Industry

The aerospace sector relies heavily on cold forging for producing critical components that require high strength and precision. As air travel continues to grow and the demand for more fuel-efficient aircraft rises, manufacturers are increasingly turning to cold forging processes to produce vital parts, further fueling market expansion.