The sports industry is witnessing a significant transformation, with 3D printing emerging as a pivotal technology that is reshaping how equipment is designed, manufactured, and distributed. The dynamics of the sports 3D printing services market are influenced by a complex interplay of technological advancements, consumer preferences, market trends, and regulatory considerations. Understanding these dynamics is essential for stakeholders looking to navigate this evolving landscape effectively.

Technological Advancements

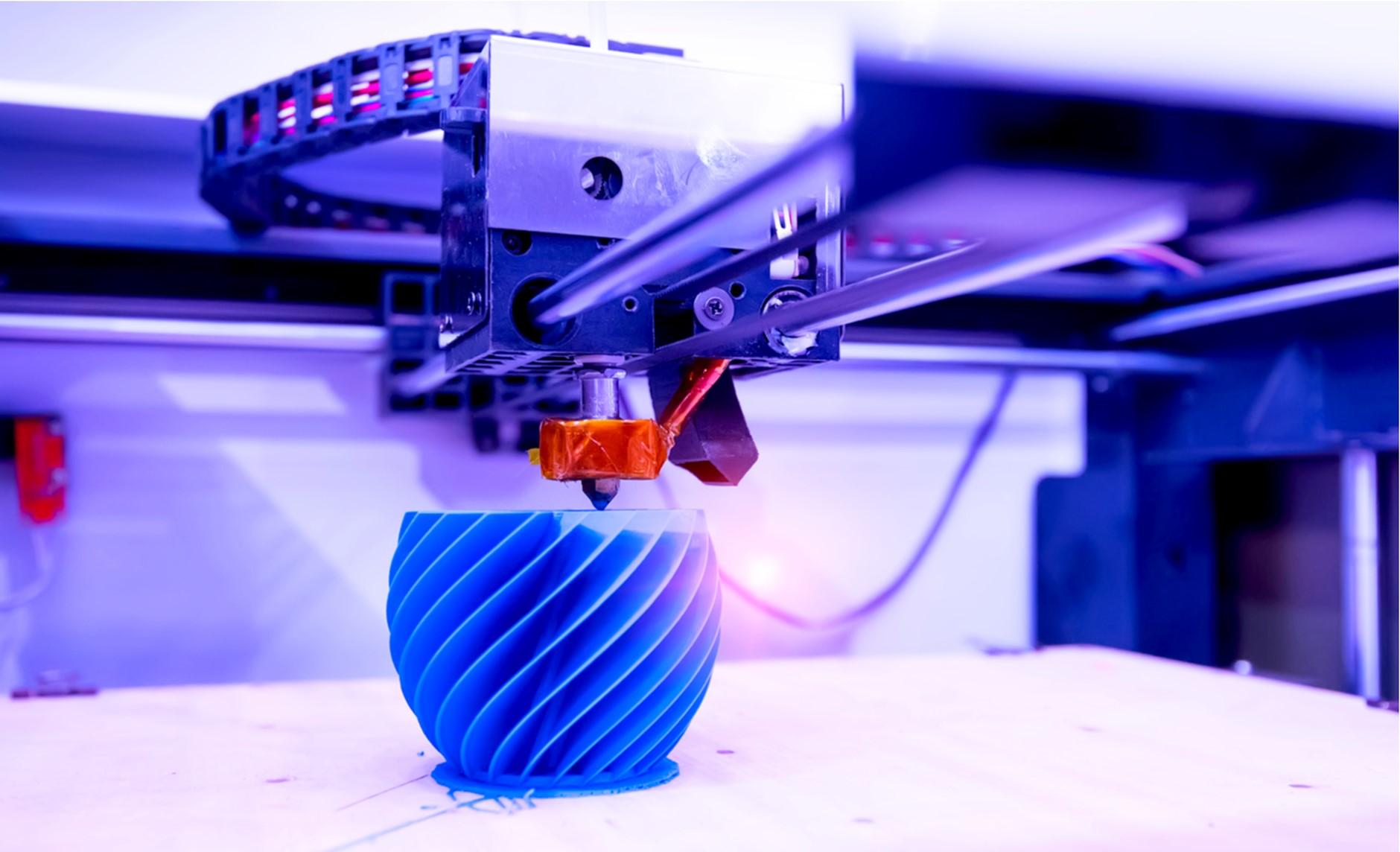

At the heart of the sports 3D printing services market are the rapid advancements in technology that have revolutionized manufacturing processes. Traditional manufacturing methods often involve lengthy lead times and substantial waste, whereas 3D printing, or additive manufacturing, allows for the production of items layer by layer, minimizing material waste and reducing production time.

Recent developments in printing technologies have enhanced the capabilities of 3D printing. Innovations such as multi-material printing and improved software for design and simulation have broadened the scope of what can be produced. These technologies allow for complex geometries and customized designs that are tailored to meet the specific needs of athletes. As technology continues to evolve, it opens new avenues for creativity and innovation in sports equipment design, making it a significant driver of market dynamics.

Growing Demand for Customization

A notable dynamic influencing the sports 3D printing services market is the increasing demand for personalized and customized equipment. Athletes at all levels—professional and amateur—are seeking gear that meets their individual specifications, including fit, comfort, and performance. Traditional manufacturing often struggles to meet these unique demands, leading to a rising interest in 3D printing solutions that offer customization.

With the capability to create bespoke items, such as custom-fitted shoes or helmets that conform to an athlete's unique measurements, 3D printing provides a competitive advantage. This shift towards personalization not only enhances the athlete's experience but also fosters brand loyalty as consumers gravitate towards companies that prioritize individualized solutions. The desire for customized sports equipment is expected to remain a significant driver of market dynamics in the foreseeable future.

Sustainability Considerations

Sustainability is becoming increasingly important in today's business landscape, and the sports industry is no exception. The environmental impact of manufacturing processes is under scrutiny, prompting companies to explore more sustainable practices. The dynamics of the sports 3D printing services market reflect this trend, as additive manufacturing offers a more eco-friendly alternative to traditional methods.

3D printing reduces material waste, as products are built layer by layer, allowing for precise use of materials. Additionally, advancements in materials science are leading to the development of biodegradable and recyclable materials suitable for 3D printing. These innovations align with the growing consumer demand for environmentally responsible products. As athletes and consumers prioritize sustainability, companies that adopt 3D printing technology and eco-friendly materials are likely to gain a competitive edge in the market.

Competitive Landscape

The competitive dynamics of the sports 3D printing services market are characterized by a diverse array of players, including established manufacturers, startups, and technology firms. This landscape fosters innovation, as companies strive to differentiate their products and services. Collaborative ecosystems are emerging, where manufacturers partner with technology providers and research institutions to drive advancements in materials, design, and production techniques.

This collaborative approach is vital for staying ahead in a rapidly evolving market. By pooling resources and expertise, stakeholders can accelerate the development of innovative solutions that cater to the changing needs of athletes and consumers. Moreover, as new players enter the market, the competition is expected to intensify, prompting existing companies to continuously innovate and adapt.

Regulatory and Compliance Factors

The dynamics of the sports 3D printing services market are also influenced by regulatory and compliance considerations. As 3D printing technology becomes more prevalent in sports equipment manufacturing, there is a growing need for standards and regulations to ensure product safety and quality. Governing bodies in sports are increasingly scrutinizing the materials and processes used in manufacturing to maintain fair play and safety standards.

Compliance with regulations can pose challenges for companies, requiring them to stay informed about evolving standards and invest in quality assurance processes. However, those that proactively address regulatory requirements can gain a competitive advantage by demonstrating their commitment to safety and quality.

Final Thoughts

The dynamics of the sports 3D printing services market are shaped by a confluence of technological advancements, consumer demand for customization, sustainability considerations, competitive forces, and regulatory factors. As the market continues to evolve, stakeholders who understand and adapt to these dynamics will be well-positioned to capitalize on the opportunities presented by this innovative technology. The future of sports equipment design and manufacturing looks promising, driven by the potential for enhanced performance, sustainability, and personalization. Embracing these dynamics will pave the way for a more efficient and responsive sports industry.