The paraffin wax market is characterized by a variety of options that cater to diverse applications and consumer preferences. As a versatile material derived from petroleum, paraffin wax is widely used in industries such as packaging, cosmetics, candles, and pharmaceuticals. This article explores the different options available in the paraffin wax market, highlighting product types, applications, and innovative alternatives.

1. Product Types

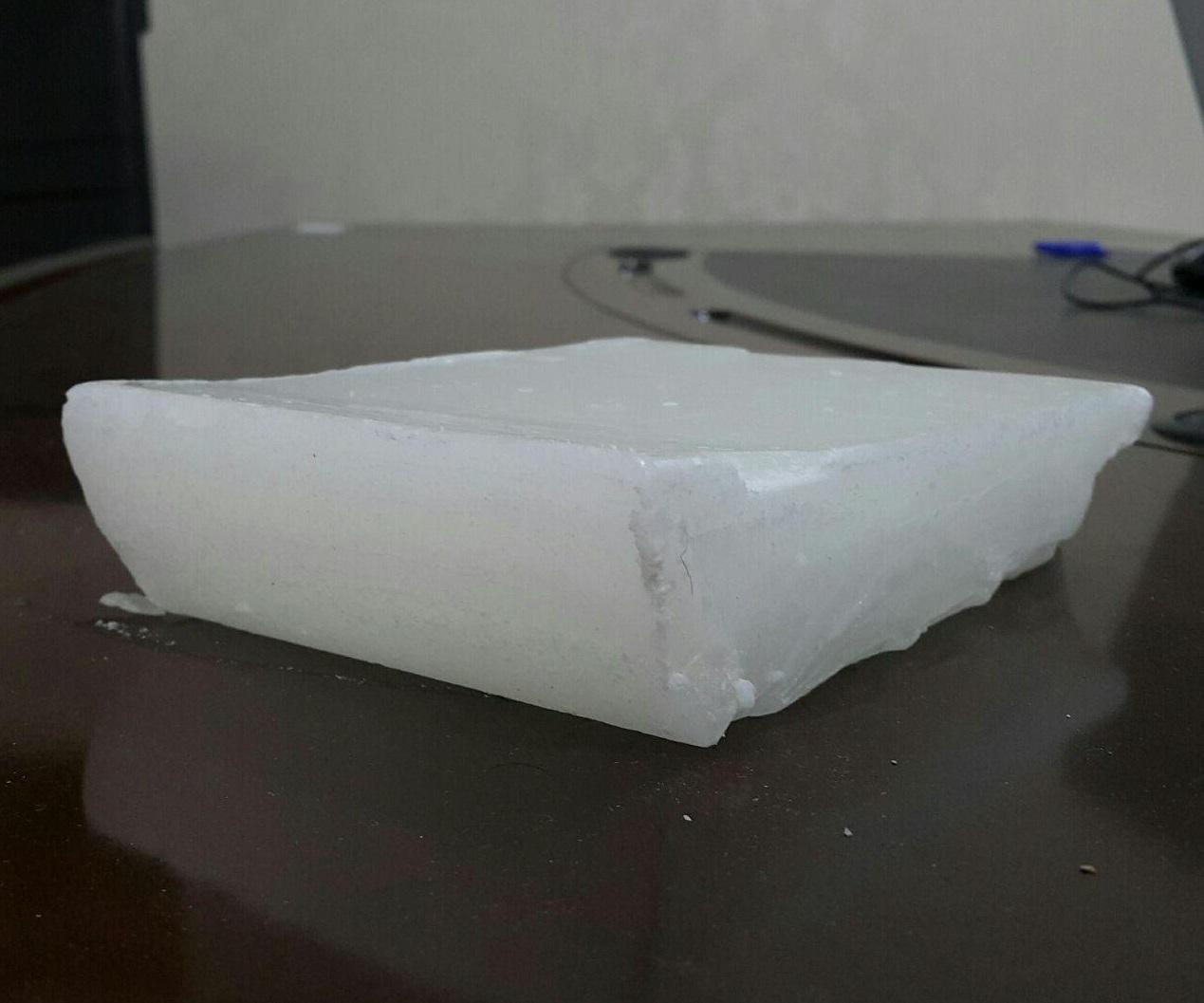

Paraffin wax is primarily classified into three main types:

-

Fully Refined Paraffin Wax: This type is the most commonly used and is known for its high purity. Fully refined paraffin wax has excellent melting points and is favored in applications requiring clean-burning properties, such as candles and food packaging. Its clarity and consistency make it an ideal choice for cosmetic formulations and personal care products.

-

Semi-Refined Paraffin Wax: This wax is less pure than fully refined paraffin wax and is often used in applications where cost is a significant consideration. Semi-refined wax finds its place in industrial uses, such as coatings and lubricants, where high purity is not as critical.

-

Microcrystalline Wax: Known for its flexibility and tackiness, microcrystalline wax is used in specialty applications, including cosmetics, adhesives, and food packaging. Its unique properties make it suitable for creating a wide range of products, from creams and lotions to food wraps.

2. Applications

The diverse applications of paraffin wax provide numerous options for manufacturers and consumers alike:

-

Candles: Paraffin wax is a dominant material in candle production, known for its ability to hold fragrance and color. Manufacturers can create a variety of candle types, including scented, decorative, and pillar candles, catering to different consumer preferences.

-

Cosmetics and Personal Care: The cosmetic industry utilizes paraffin wax in a variety of products, including lip balms, lotions, and creams. Its emollient properties help to create smooth, moisturizing formulations that enhance skin feel.

-

Packaging: In the packaging sector, paraffin wax is used for moisture-resistant coatings, particularly for food products. Its barrier properties help maintain the freshness of packaged goods, making it an essential component in food safety.

-

Industrial Uses: Paraffin wax also finds applications in various industrial processes, including lubrication, insulation, and coatings. Its versatility makes it suitable for a range of technical applications.

3. Innovative Alternatives

As consumer preferences shift towards sustainability, manufacturers are exploring innovative alternatives to traditional paraffin wax. These options include:

-

Bio-Based Waxes: Plant-derived waxes, such as soy and palm wax, are gaining popularity due to their renewable nature. These eco-friendly alternatives cater to environmentally conscious consumers and are often marketed as sustainable options in the candle and cosmetics industries.

-

Blended Waxes: Combining paraffin wax with other natural waxes can create unique formulations that enhance performance while appealing to sustainability-minded consumers. These blends can offer improved burn quality in candles and better emollient properties in cosmetics.

4. Conclusion

The paraffin wax market offers a wide array of options for manufacturers and consumers, ranging from various product types to diverse applications. While traditional paraffin wax remains a staple in many industries, the emergence of innovative alternatives presents new opportunities for growth. By embracing sustainability and exploring the unique properties of different waxes, stakeholders can adapt to changing market demands and position themselves for success in this dynamic landscape. The future of the paraffin wax market will likely see a blend of traditional uses and innovative solutions that meet the evolving needs of consumers.