Unlocking the Potential: The Growth of the Saudi Arabia Machine Tools Market

Market Overview

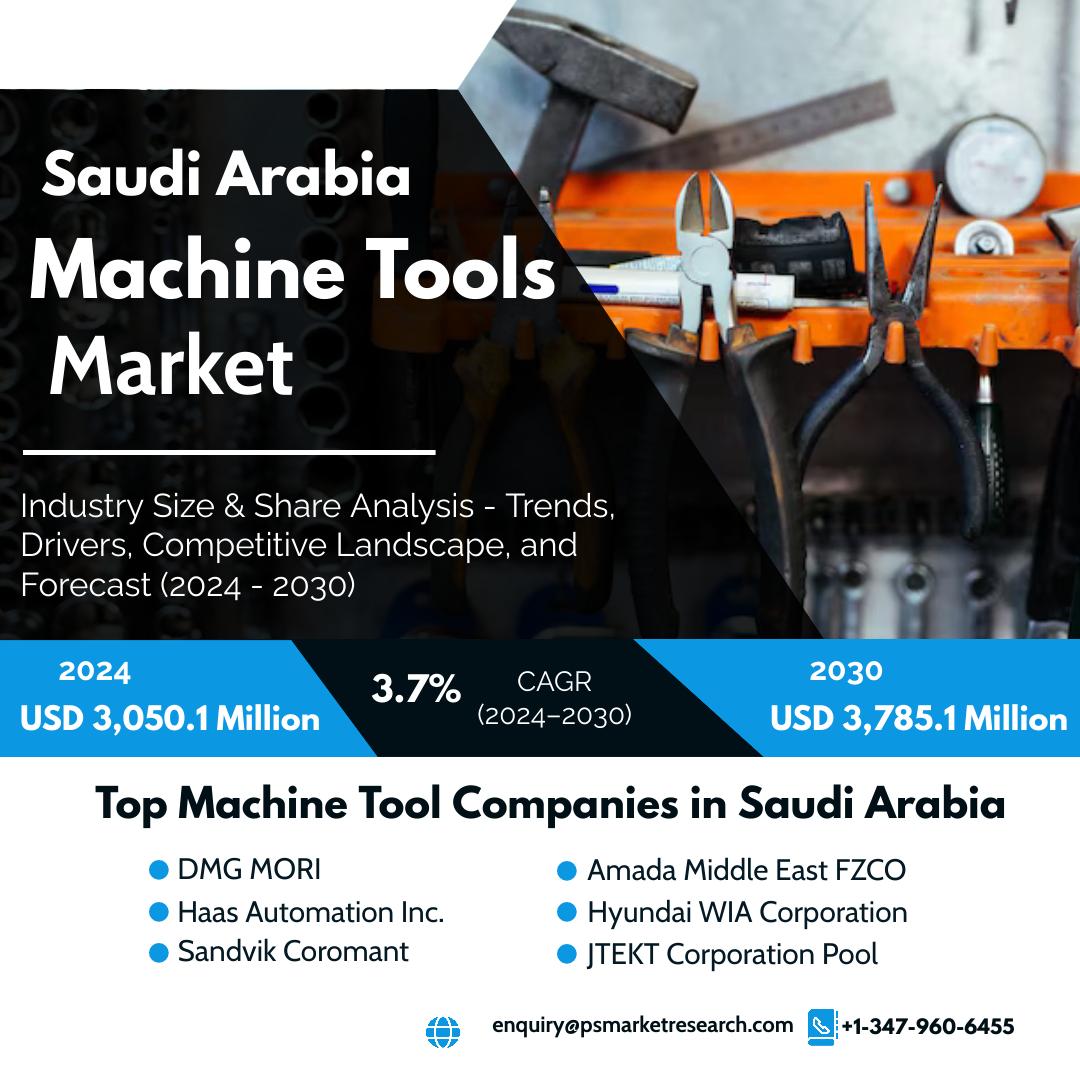

The Saudi Arabian machine tools market is projected to generate approximately USD 3,050.1 million in revenue in 2024, with an expected CAGR of 3.7% from 2024 to 2030, reaching USD 3,785.1 million by 2030. This growth is driven by advancements in machine tools and a rising demand for manufactured goods across various industries, prompting the need for efficient and specialized tools to meet modern manufacturing complexities.

A significant trend in the market is the increased adoption of CNC machine tools, which offer benefits such as enhanced efficiency, precision, and the ability to manage intricate tasks. These tools are compatible with a variety of materials, boast greater durability, and enable higher productivity while minimizing human labor and errors.

Additionally, the integration of smart manufacturing technologies such as AI, machine learning, and IoT facilitates real-time monitoring, optimizes operations, and supports predictive maintenance. There is also a growing use of robotics and automation in manufacturing, which reduces labor costs and boosts output.

The demand for precision engineering in major cities like Jeddah, Riyadh, and Dammam is further fueling the need for advanced machine tool solutions. Industries such as aerospace, automotive, and medical devices require highly accurate components, driving investments in precision engineering technologies. These high-precision tools enhance industrial efficiency by minimizing errors and waste, leading to cost reductions and increased productivity.

Key Insights

· The metal-cutting category is expected to grow at a CAGR of 4.0% during 2024–2030.

· It will hold a larger market share of 65% by 2030, driven by high accuracy and versatility requirements in metal shaping and cutting.

· Essential tools in this category include lathes, mills, drilling machines, and grinders.

· Key industries utilizing metal cutting tools include aerospace, energy, automotive, and general manufacturing.

· Saudi Arabia's Vision 2030 is leading to increased infrastructure investments, boosting the demand for metal cutting tools.

· The CNC category is projected to have a larger market share of 70% by 2030, growing at a higher CAGR during the same period.

· CNC tools offer superior efficiency and precision, making them ideal for intricate components in aerospace, automotive, and electronics.

· These machines reduce human errors and enhance productivity compared to traditional tools.

· Industry 4.0 and smart manufacturing trends emphasize the importance of CNC machines.

· The automotive and transportation sector will account for the largest share in 2024, driven by technological advancements and investments.

· Machine tools are essential for fabricating small components and cutting metals in the automotive sector.

· The electrical and electronics category is expected to grow at the highest CAGR, driven by the need for precise components like microchips and PCBs.

· Advanced tools such as laser cutters and CNC machines are vital for producing high-tolerance electronic components.

· The Eastern Region will hold a market share of 40% in 2024 and exhibit a CAGR of 4.5%.

· The market is fragmented, featuring both local and international players, with mergers and acquisitions facilitating industry expansion.

Source: P&S Intelligence

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Игры

- Gardening

- Health

- Главная

- Literature

- Music

- Networking

- Другое

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness