How Multistage Centrifugal Pumps Adapt to Different Flow Rate Demands

What Are Multistage Centrifugal Pumps?

Definition and Key Characteristics

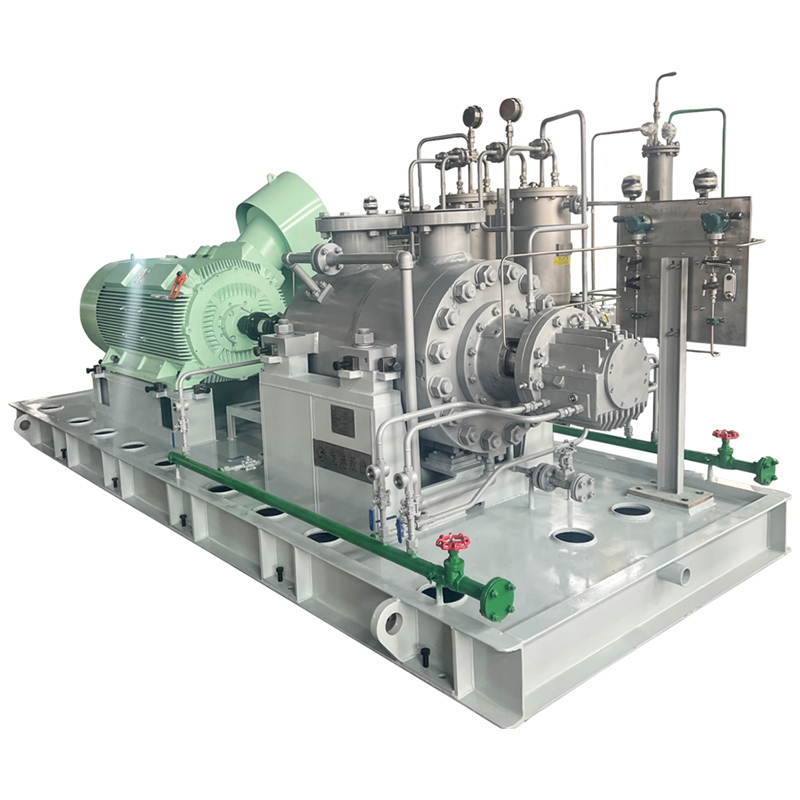

Multistage centrifugal pumps are engineered to handle large volume transport across various industries. These pumps utilize multiple impellers, which enable the elevation of fluid to significant heights and the sustenance of a consistent flow rate. The key characteristics include efficient energy usage, adaptability to varying operational conditions, and the potential to manage different liquids with precision. The arrangement of stages facilitates the increase in pressure, making these pumps ideal for applications requiring a higher head.

Yantai Longgang Pump Industry Co., Ltd. Expertise

Yantai Longgang Pump Industry Co., Ltd. specializes in the production and development of innovative multistage centrifugal pumps. With a strong commitment to quality, the company leverages state-of-the-art technology and research to deliver reliable and efficient pumping solutions. Their extensive experience covers a range of industries, including water supply, petrochemical, and HVAC applications. By focusing on customer-centric designs and sustainable practices, Yantai Longgang establishes itself as a leader in the global pump market.

How Do Multistage Centrifugal Pumps Adjust for Varying Flow Rates?

Stages in Multistage Centrifugal Pumps

The adaptation to varying flow rates in multistage centrifugal pumps is primarily achieved through the incorporation of additional impellers. Each stage contributes to the overall pressure increase and flow control, allowing the pump to efficiently manage a range of flow demands. By modifying the number of activated stages, operators can tailor the pump's performance to meet specific operational requirements without compromising energy efficiency. This versatility is instrumental in applications where flow rate and pressure need to be dynamically balanced.

Series and Parallel Configurations

Multistage centrifugal pumps can be configured in both series and parallel arrangements to meet fluctuating flow or pressure requirements. A series configuration allows for successive stages to intensify pressure, ideal for high-head applications. Conversely, a parallel configuration can divide the flow between multiple pumps, enhancing the system's overall capacity while maintaining efficiency. This adaptability enables engineers to devise customized pumping solutions that precisely align with their project's demands.

How Is Performance Optimized in Different Applications?

Variable Speed Drives (VSD)

The integration of Variable Speed Drives (VSD) represents a significant advancement in optimizing the performance of multistage centrifugal pumps. VSDs allow for real-time adjustments to the pump speed based on system demand, leading to improved efficiency and reduced wear and tear on components. This technology helps maintain optimal flow rates and pressure levels in diverse applications, thereby enhancing the overall lifespan of the pump while lowering energy costs.

Split Double Suction Centrifugal Pump

Additionally, employing split double suction centrifugal pumps offers a unique solution for handling varying flow rates. This design minimizes the axial thrust and balances the flow, significantly improving pump performance in applications dealing with high volumes. These pumps provide enhanced hydraulic efficiency and reliability, making them suitable for both variable and constant flow conditions across many industries.

Are Maintenance and Durability Affected by Flow Rate Variations?

Regular Maintenance Practices

The performance and durability of multistage centrifugal pumps can indeed be affected by variations in flow rates. Regular maintenance practices, such as monitoring wear on impellers and seals, are essential to ensure optimum functionality. Variable flow rates may lead to wear patterns that necessitate more frequent inspections to prevent failures. Implementing scheduled maintenance helps in prolonging the operational life of the pumps and maintaining their efficiency.

Advanced Material Choices

Moreover, selecting advanced materials for the construction of pump components is imperative to enhance durability under varying flow conditions. Components made of high-performance alloys and resilient composites can withstand corrosion and wear, thereby extending the life of the pump. These material considerations play a crucial role in sustaining performance and reliability while managing variances in flow and pressure effectively.

Future Trends in Multistage Centrifugal Pump Technology

Innovations in Design

The future of multistage centrifugal pump technology is poised to be shaped by several innovations in design and efficiency. Innovations include smart monitoring systems and advanced hydraulic models that enable predictive maintenance and real-time performance analysis. By embracing these technologies, manufacturers can maximize efficiency, improve user experience, and reduce environmental impact. These trends reflect a growing commitment to engineering excellence and operational sustainability.

Sustainability Considerations

Incorporating sustainability considerations into multistage centrifugal pump design represents another critical trend. Efforts are being directed toward creating eco-friendly pumps that minimize energy consumption while maintaining robust performance capabilities. Emphasizing sustainability not only addresses regulatory demands but also aligns with the broader goals of reducing the carbon footprint in industrial operations.

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- الألعاب

- Gardening

- Health

- الرئيسية

- Literature

- Music

- Networking

- أخرى

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness