Permanent Magnet Motors Benefit Compressors

PREVIEW

• What are the drawbacks to induction motors?

• The benefits of permanent magnet motors

• PM VSD Screw Air Compressor Features and Advantages

• Advantages of permanent magnet motors compared to general asynchronous motors

• Power-saving effect

What are the drawbacks to induction motors?

Unlike permanent magnet motors, induction motors use two parts: a stationary stator and a rotating rotor. The electric current passes through the stator to produce a rotating magnetic field. This in turn induces a current in the rotor, which creates a second magnetic field. The interaction between these two magnetic fields produces turning torque, causing the rotor shaft to turn.

But the induction motor shaft and the magnetic field do not turn at the same pace. Due to losses in bearings and other elements, the rotor cannot keep up with the field and is usually below the magnetic field synchronous speed by approximately 1-5%. This is called slip. Over time, slip can cause damage to your motor and compressor.

The benefits of permanent magnet motors

High-speed permanent magnet motors offer increased energy efficiency compared to conventional asynchronous induction motors. A permanent magnet motor has air-cooled winding heads and water-cooled housing for reliable operation, and extremely low loss lamination grade material in the motor core result in low iron losses. Non-contact magnetic bearings are used to hold the motor shaft in place, so there is less vibration and no friction between the components, resulting in less wear.

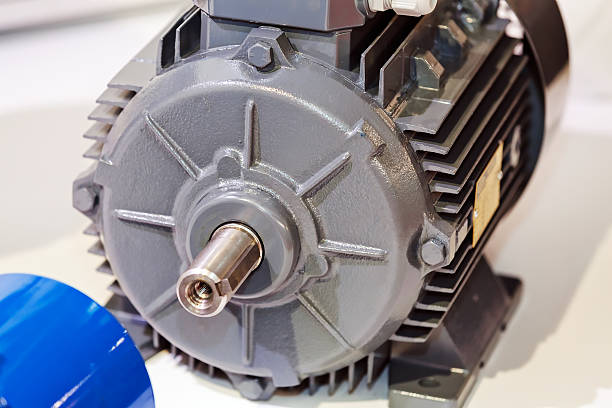

The air compressor utilizes a permanent magnet motor for superior performance and extended lifespan.

PM VSD Screw Air Compressor Features and Advantages

1. Ultra-low temperature rise design, which allows the compressor to run at an ultra-low frequency for a long time.

2. Closed-loop vector control system for faster control and more precise speed control.

3. The compressor unit can still operate efficiently when the frequency is reduced by more than 50%.

4. The pressure is stable and the pressure fluctuation is accurately controlled within 0.1 bar.

5. The figure shows a comparison of several starting methods. It can be seen that the frequency converter is slowly accelerated to start, the starting is more stable, and the current peak is completely avoided.

Advantages of permanent magnet motors compared to general asynchronous motors

1. High efficiency: eliminates excitation system losses and improves efficiency.

2. It is still efficient under low load conditions: the energy efficiency of a permanent magnet motor is more than 9% higher than that of a conventional asynchronous motor at full load operation, and its energy efficiency remains unchanged as the speed decreases.

3. Large overdrive torque: the ratio of the maximum starting torque of the permanent magnet synchronous motor to the rated torque can be more than 3 times, while the general asynchronous motor is only 1.6 times.

4. The control is more stable: the corresponding time of the permanent magnet motor is <50ms, and the gas production can be adjusted in a large range in an instant so that the gas pressure is truly stable.

Enneng can provide permanent magnet motors, as well as complete permanent magnet air compressors.

Power-saving effect

The customer uses a single-stage compression 160kw, 7kg machine with a gas volume of 28.5 cubic meters.

If we use our permanent magnet frequency conversion and two-stage compression, 132kw/7.5kg, the air volume is 30 cubic meters, the power is reduced, the air volume is increased, and the energy-saving rate is very good.

The original machine full load power consumption 192kw

The new machine has a full load power consumption of 150kw

Save 42kw per hour

Operating 24 hours a day, the comprehensive electricity fee is 0.8 yuan/kw

Save 42*24*0.8=806 yuan every day

Save 42*24*30*0.8=24192 yuan per month

Save for 11 months every year

42*24*30*11*0.8=266112 yuan

The cost can be recovered in about 1 year.

Enneng TYB Series Standard Type Permanent Magnet Motor adopts high-efficiency NdFeB permanent magnet, no excitation loss, and through special rotor structure design, greatly reduce iron loss and stray loss, the efficiency of the whole machine reaches above IE4 standard, the efficiency is increased by 5-10%, and the power factor is improved 10-15% or more. Enneng Permanent Magnet Motor is famous for its small size, high power factor, high efficiency and energy saving. With the value Technology is how we do things. People are why we do things in mind, Enneng is devoted to the research and development of various special high & low voltage Low-speed High-torque permanent magnet motors, constant-speed permanent magnet motors, and special direct-drive permanent magnet motors. If you have any needs, please contact us and we will reply to you as soon as possible.

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Jogos

- Gardening

- Health

- Início

- Literature

- Music

- Networking

- Outro

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness