Basalt Fiber Market: Navigating Growth Trends and Future Opportunities

The basalt fiber market is gaining significant traction due to its unique properties and diverse applications across various industries. This article explores the current trends shaping the basalt fiber landscape, highlighting factors driving growth, emerging applications, and the challenges that stakeholders face.

Overview of Basalt Fiber

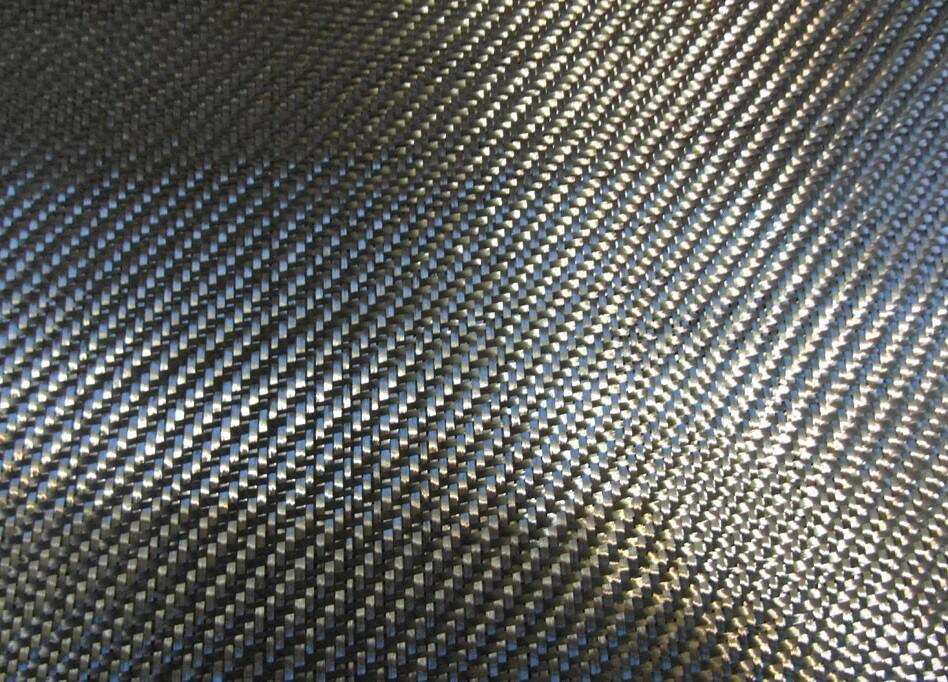

Basalt fiber is produced from volcanic basalt rock, which is heated and drawn into fibers. This material exhibits high tensile strength, excellent thermal stability, and resistance to corrosion, making it an attractive alternative to traditional fibers such as glass and carbon. As industries seek to enhance the performance and sustainability of their products, basalt fiber emerges as a viable solution.

Growing Demand in Construction and Infrastructure

One of the most significant trends in the basalt fiber market is its increasing adoption in the construction sector. As countries invest in infrastructure development, there is a rising demand for materials that offer durability and sustainability. Basalt fiber reinforced concrete (BFRC) is particularly gaining popularity due to its lightweight properties and enhanced mechanical performance. This material not only contributes to the longevity of structures but also reduces maintenance costs over time.

Moreover, the shift towards green building practices is propelling the use of basalt fiber. As sustainability becomes a focal point for developers and architects, materials that reduce environmental impact without compromising performance are in high demand. Basalt fiber’s natural origins and recyclability position it favorably within the context of sustainable construction.

Expansion in Automotive and Aerospace Industries

Another noteworthy trend is the growing utilization of basalt fiber in the automotive and aerospace industries. The push for lightweight materials to improve fuel efficiency and reduce emissions is influencing manufacturers to explore alternatives to traditional composites. Basalt fiber’s excellent strength-to-weight ratio makes it an attractive option for components such as body panels and structural elements.

In the aerospace sector, where performance and safety are paramount, basalt fiber composites are emerging as a key material. Their resistance to extreme temperatures and chemicals aligns well with the stringent requirements of aviation applications. As OEMs (Original Equipment Manufacturers) prioritize innovation and sustainability, basalt fiber is increasingly seen as a competitive solution.

Innovations in Product Development

Innovation is a cornerstone of the basalt fiber market, with ongoing research aimed at enhancing its properties and expanding its range of applications. The development of hybrid composites that combine basalt fiber with other materials is gaining momentum. Such composites can optimize performance characteristics, addressing specific industry needs while maintaining cost-effectiveness.

Moreover, advancements in manufacturing technologies are reducing production costs and improving the availability of basalt fiber. This is expected to further catalyze its adoption across various sectors. As the industry matures, stakeholders are increasingly focusing on the creation of standardized products that meet regulatory requirements and consumer expectations.

Increasing Focus on Research and Development

Investment in research and development (R&D) is pivotal for driving growth in the basalt fiber market. Collaborations between industry players, academic institutions, and government agencies are fostering innovation and exploring new applications. R&D efforts are not only aimed at improving the physical properties of basalt fiber but also at exploring novel manufacturing processes that enhance efficiency.

The emergence of new applications in fields such as wind energy and sports equipment is a testament to the potential of basalt fiber. As companies seek to diversify their product offerings, exploring these niche markets can yield significant opportunities for growth.

Competitive Landscape and Market Dynamics

The basalt fiber market is characterized by a diverse range of players, from established manufacturers to emerging startups. This competitive landscape fosters innovation and drives advancements in product offerings. As more companies enter the market, the focus on differentiation becomes crucial. Companies are investing in branding and marketing strategies to educate consumers about the benefits of basalt fiber, emphasizing its superior properties over traditional materials.

Moreover, strategic partnerships and collaborations are increasingly common as companies seek to leverage complementary strengths. These alliances can enhance distribution networks, expand market reach, and enable shared R&D initiatives, creating a win-win scenario for stakeholders involved.

Challenges and Considerations

Despite its growth potential, the basalt fiber market faces several challenges. One of the primary hurdles is the relatively high cost of production compared to traditional fibers. While the benefits of basalt fiber are well recognized, cost competitiveness remains a key factor for widespread adoption. Industry players are actively exploring ways to streamline manufacturing processes and reduce costs without compromising quality.

Additionally, market awareness and education remain critical. Many end-users are still unfamiliar with basalt fiber and its advantages. Efforts to raise awareness through targeted marketing campaigns, industry events, and educational initiatives are essential for driving adoption across various sectors.

Conclusion

The basalt fiber market is poised for substantial growth, driven by rising demand in construction, automotive, and aerospace industries, along with ongoing innovations and R&D efforts. While challenges such as production costs and market awareness persist, the unique properties and sustainability credentials of basalt fiber position it as a material of choice for the future. As the market evolves, stakeholders must remain agile, embracing collaboration and innovation to harness the full potential of basalt fiber in the years to come.

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Παιχνίδια

- Gardening

- Health

- Κεντρική Σελίδα

- Literature

- Music

- Networking

- άλλο

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness