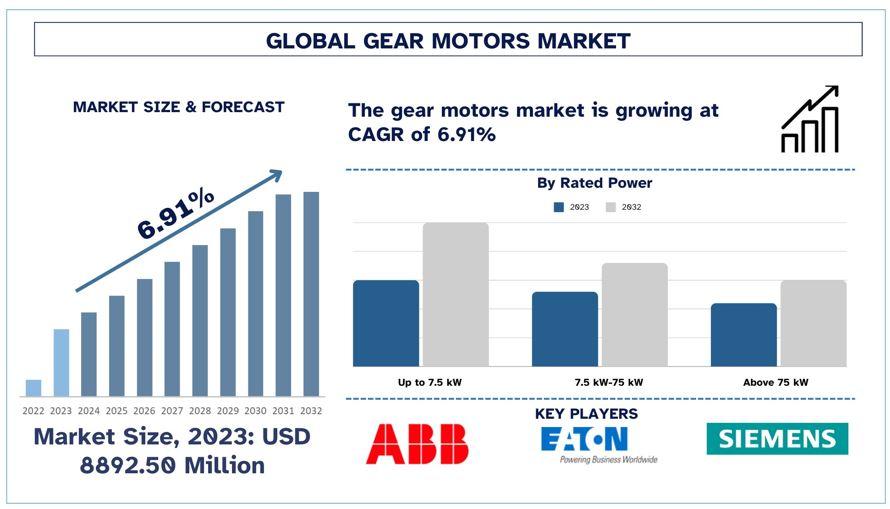

According to a new report by UnivDatos Market Insights, the Gear Motor Market is expected to reach by 2032 by growing at a CAGR of ~6.91 %.

Introduction

The market for gear motors around the world has expanded in the recent past due to technological developments and increasing demand, increasing automation, and increasing demands for energy-efficient solutions. Gear motors can be described as a motor and a gear system that work hand in hand in most industries as they provide accuracy, reliability, and efficiency in operations. This article gives an understanding of the gear motors market through an analysis of factors including demand, use, cost, and production of gear motors with a focus on the prospects of the industry.

Demand

The demand for gear motors is heavily correlated with the general ideas of industrial automation and Industry 4.0. This is especially so since industries the world over are pushing for greater efficiency, accuracy, and dependability of operations and gear motors play a very crucial role in driving many types of equipment. This includes manufacturing, automotive, food and beverage, material handling, and renewable energy industries are among some of the industries that have shifted to using gear motors to upgrade their processes.

The start of Industry 4. 0, inhabited by IoT (Internet of Things), smart technologies, and data analytics in industrial systems, has fomented the demand for sophisticated gear motors. These smart gear motors include sensors and connectivity that help in identifying the performance and even the problems that may arise hence helping in remote control and preventing unnecessary downtime in business. Besides, the increasing awareness of sustainable development all over the world also creates the need for efficient gear motors for the consumption of less energy in operation and therefore cutting down on cost.

Applications

Gear motors are highly useful parts utilized in almost all types of industries and for practically any purpose. In the manufacturing industry, they are used in conveyors, packaging equipment, and assembling lines where accuracy and durability are valued. Gear motors are commonly used in the automotive industry in areas such as windshield wipers, seat adjusters, and electric windows as part of electric car initiatives. In the renewable energy industry, gear motors are used in wind power generators and tracking systems for the solar panel's conversion of kinetic energy to electrical energy. Gear motors are used to drive mixers/blenders, feed and bottle conveyors, packaging machines, and other equipment that the food and beverage industry cannot do without. Also in systems like cranes, hoists, and elevators, gear motors supply the necessary power and control to handle materials safely and effectively.

Cost

The prices also differ according to the complexity of the design, the type of material used, the power rating, and whether the gear motors are ordered from scratch. Standard gear motors with the least measurement are cheaper and easier to find compared to the others with high specifications. Yet, gear motors that are developed for certain purposes or designed for certain sectors are usually costlier as compared to the regular ones, or because of the incorporation of features such as IoT, smart sensors, or sturdiness.

Request Free Sample Pages with Graphs and Figures Here https://univdatos.com/get-a-free-sample-form-php/?product_id=64850

High-efficiency gear motors may be expensive to purchase and have lower costs in the long run in terms of energy consumption and replacement costs. Customers who are thinking of acquiring gear motors would be curious about the total cost of owning the product as that has to do with the buying price, the costs of energy, maintenance, and even losses from potential breakdowns.

To reduce costs, the manufacturers of gear motors are now concentrating on delivering solutions that are feasible according to the price without displaying low functionality or standards. New technologies have continued to be developed in manufacturing and these include automation processes together with the manufacturing of new gears through additive manufacturing at a cheaper price as compared to the previous prices hence better quality of the gear motors of the industries.

Manufacturing

The making of the gear motors is lengthy and requires a lot of input in terms of engineering and quality materials. It usually starts at the design stage whereby engineers work on the specifications that will be put into use depending on the intended use and performance standards. Since a gear motor is a mechanical system, then to design it, solid modeling or computer-aided design (CAD) is employed to develop detailed design models of the motor, gears, housing, and bearings.

In the manufacturing process of automobiles, when the design of the automobile is completed, automobile parts are produced with steel aluminum and copper materials, etc. Gear motors are produced mechanically and some advanced manufacturing processes like CNC machining, injection molding, and die casting are adopted in the production of the gear motors to ensure that are well made and are likely to have the same specifications. The gears that are used in the construction of the gear motor are produced through gear-cutting, grinding, or even heat treatment of materials to have the required surface hardness of the gear.

The reduction gears are manufactured and then again followed by assembling the final gear motor unit. This is an assembly process where the gears, the motor, and the housing are duly aligned and assembled to fit the needed standard of working. Reliability control is one of the important stages of checking and testing of the gear motor to ensure that it is strong, durable, and adheres to the market standards.

The development of automation in manufacturing industries has also shoved to the production by automated assembly lines, and robotic systems to reduce the production time of the gear motors. Moreover, the active use of the concept of Industry 4.0. Even though there exist zero principles in manufacturing, it has facilitated the employment of various monitoring systems and analysis of production processes to enhance the quality of gear motors while reducing their costs.

Conclusion

The gear motors market on the global platform shall witness growth shortly due to factors such as the need for automation, energy conservation, and the incorporation of the Smart movement in all fields. Gear motors provide significant contributions to the efficiency and durability of industrial apparatus making them vital in industries like production, automotive, renewable energy, and lifting operations.

The main expectation in the future of gear motors will be based on the new trends that are currently developing on the market such as the connection of IoT and smart sensors, energy-efficient solutions, and the application of new materials and manufacturing technologies. Currently, companies in the global gear motor have applied innovation, further differentiation, and better costs to satisfy other customers’ requirements and changes to be more competitive.

Therefore, the gear motor market is not only a needful element of contemporary industry, but it is also a progressive and quickly developing market that keeps contributing to the advancement of efficiency and technologies in the worldwide industry. Thus, gear motors will remain relevant, and will continue to be the leading force behind the industrial growth in the future due to continued technology and manufacturing innovations.

Report

Market Size, Trends, & Forecast by Revenue | 2024−2032.

Market Dynamics – Leading Trends, Growth Drivers, Restraints, and Investment Opportunities

Market Segmentation – A detailed analysis of gear type, end-users, and rated power.

Competitive Landscape – Top Key Vendors and Other Prominent Vendors

Contact Us:

UnivDatos Market Insights

Email - contact@univdatos.com

Contact Number - +1 9782263411

Website -www.univdatos.com