Global Gear Motors Market: Key Trends and Developments Shaping the Industry

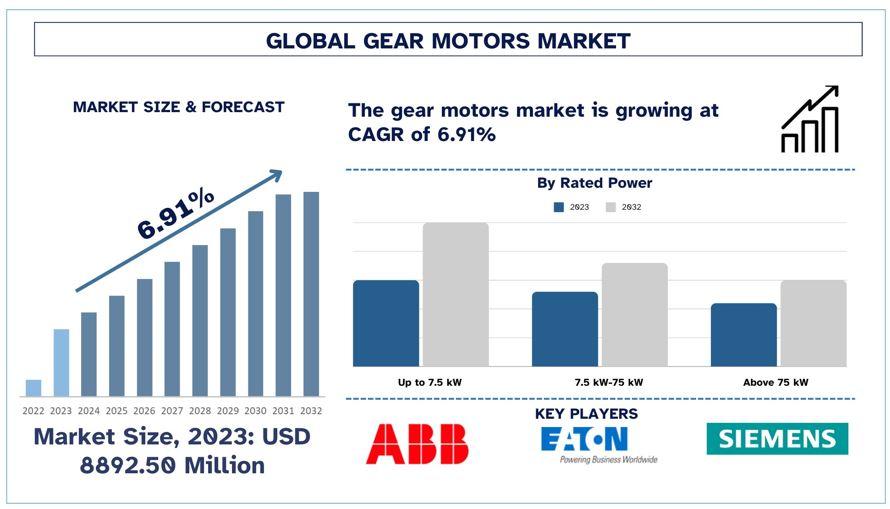

According to the UnivDatos Market Insights analysis, the growth of gear motors is primarily driven by the increasing demand for automation across various industries. As manufacturing, automotive, and logistics sectors adopt advanced technologies to enhance efficiency and productivity, gear motors have become crucial components in these automated systems. Their ability to provide precise control, reliable performance, and integration with modern robotics and conveyor systems has fueled their widespread adoption, driving market expansion. As per their “Gear Motors Market” report, the global market was valued at USD ~ 8892.50 million in 2023, growing at a CAGR of about 6.91% during the forecast period from 2024 – 2032.

The global gear motors market is in the middle of a transition, as more innovations emerge, and new sectors rise to prominence while other industries decline slowly. With industries all over the world adopting automation digitalization and technological advancement, the gear motors market is still growing and incorporating new trends that are key to the future of the market. The current nature of developments in the gear motors industry, along with its innovations, has been the focus of this article; their significance in distinct areas is also discussed.

Smart Gear Motors and The Paradigm Shift

The integration of smart gears is perhaps one of the key driving forces in the current gear motors market. It is part of the more extensive Industry 4.0, No movement, gear motors being outfitted with sensors, connectivity options, and IoT to facilitate real-time monitoring of gear motors to predict when they need repairs and for remote control. This trend is making gear motors evolve from being mere mechanical devices and switching them into smart devices that can monitor, analyze, and self-adjust to improve their performance, reliability, and efficiency.

Smart gear motors are the most useful in industries that require motors to operate 24/7 and be as reliable as possible – industries that deal with/ manufacturing, handling of material, and renewable energy. Smart gear motor solutions give real-time data and efficiency measurements including the temperature, vibration, and torque so that operators can note inconsistencies before they cause damage. Out of this capability, gear motor durability is enhanced besides benefiting from cost savings due to reduced forced maintenance and energy usage.

Energy Efficiency and Sustainability

With changes in attitude towards energy usage and the well-being of the environment, there is a growing need for gear motors that are energy efficient. The management systems that are in demand today are those that can lead to a decrease in carbon emissions, and the optimization of expenses, and therefore energy efficiency becomes the key goal. To meet consumers’ demand and changes in technology and application of equipment where gear motors have been used, manufacturers of gear motors have developed high-efficiency gear motors, built with new and improved materials, and with more efficient gear arrangements that result in energy loss.

In the renewable energy products like wind turbines and most of the places where energy conversion is inherent, gear motors are extensively used. growing importance of renewable energy is creating need for gear motors which perform well under different load conditions and severe operating conditions. Also, more recent rules and governing regulations that apply pressure on the consumption of energy in the industrial processes compel the manufacturers of gear motors to come up with highly efficient motors.

Request Free Sample Pages with Graphs and Figures Here https://univdatos.com/get-a-free-sample-form-php/?product_id=64850

Customization and Industry-Specific Solutions

Another sustainable trend in the gear motors market is the rising interest in specialty products that may be developed to meet the requirements of corresponding industries. That is why, although standard gear motors are still in great demand, there is a present trend in the development of gear motors for specific applications. This trend is however especially apparent in some industries like the automotive industry, food and beverages, and equipment manufacturing industries where there is a need to meet specific operational difficulties by use of specific gear motors.

Looking at passenger cars, for instance, the adoption of electric vehicles is putting into demand smaller, high-torque gear motors that can deliver adequate torque and energy efficiency required for EV drive systems. For the food and beverage industries, the gear motors are required to have a high level of hygiene compliance due to high-frequency cleaning hence leading to the creation of corrosion and sealed gear motor designs. Originality is now considered as one of the industry growth strategies for gear motor manufacturers because more and more industries require not only products that address their needs and requirements but also contribute positively to how their operations are being managed and improved.

Technological Advancements and Innovation

Disruptive technological advancement remains a mainstay for the gear motors market given that products are being advanced based on material science, manufacturing technology, and IOT among other fields. Probably, the novel utilized area is an application of new material, including high-strength alloy and composite, which can realize high durability, lightweight, and high performance. These materials are however crucial in applications where gear motors are likely to operate at large loads, hot environments, or where they are likely to be exposed to corrosive agents.

Another sphere of development is that of miniaturized and lightweight gear motors that are being called for use in scenarios where the available space is restricted or where the weight of the gears forms a vital factor. Such strategy is especially valuable in aerospace, robotics, and medical technologies industries where small high torque gear motors can be employed to make overall gear and system size considerably smaller and more efficient. Further, the growth of manufacturing technologies like Additive Manufacturing (3D Printing), Precision Machining, and other tools allowed the creation of those complex gear designs that were earlier itself were impossible.

Another factor that is making the gear motors market innovative is the digitization of technologies. For instance, digital twins are being employed to carve out precise replicas of gear motors to show how they would perform in certain circumstances or environments to enable the manufacturer to make the most of these designs and to flag up any problems that might arise. They are also used for handling predictive maintenance, which allows the operators to assess the status of the gear motors and establish when the maintenance is needed instead of using the time-based approach.

Focusing on regional development and rising markets

Currently, the growth of the gear motors market is observed in regions such as Asia-Pacific, North America, and Europe due to industrialization infrastructural development and the growing trend of automation. Thus, Asia-Pacific is set to become one of the dominant markets of gear motors with countries like China, India, and Japan increasing their investments in the manufacturing industry, automotive market, and renewable energy sources. The increased industrial development along with urbanization is a concern for gear motors in material handling to power generation across the region

Conclusion

The global gear motors market is at present in a phase of evolution, owing to the advancements in technology, the shifting trend in the industry, and the increased consciousness towards environmental sustainability. Several trends like smart and energy-efficient technologies and the need for personalized systems are the industry drivers. Manufacturers are constantly advancing and adjusting to these trends, and therefore the market for gear motors is anticipated to maintain steady growth and open new opportunities for the various industries.

With costs as well as the complexity of designing printed circuit boards increasing steadily, market players will probably continue to look for ways of optimizing the performance of substrates without causing a genesis of cost on the environment. The future of gear motors can be concluded as follows: Gear motors will always have a significant demand because industries are only transferring and enhancing themselves to digital structures. The growth of the gear motors market is continuous with several new innovations planning to enhance the prospects of productivity, dependability, and eco-friendly possibilities extending for diverse applications.

Contact Us:

UnivDatos Market Insights

Email - contact@univdatos.com

Contact Number - +1 9782263411

Website -www.univdatos.com

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- الألعاب

- Gardening

- Health

- الرئيسية

- Literature

- Music

- Networking

- أخرى

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness