Flexitanks have emerged as a versatile and cost-effective solution for transporting a wide range of liquid products. These large, flexible bladders are designed to fit inside standard shipping containers, offering significant advantages over traditional bulk transport methods. From chemicals to food and beverages, flexitanks are revolutionizing the way liquids are moved across the globe.

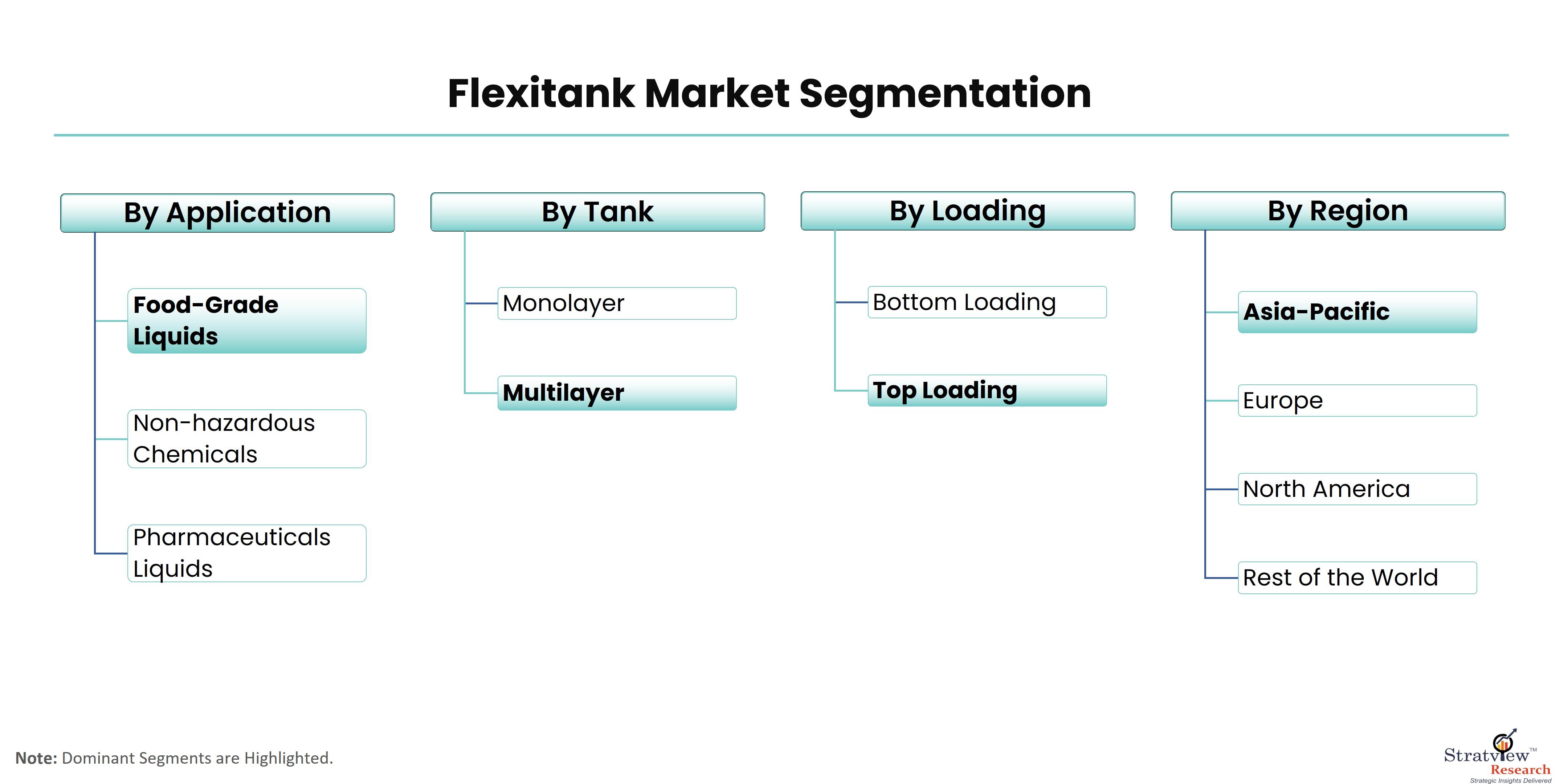

According to Stratview Research, the flexitank market was estimated at USD 807.95 million in 2022 and is likely to witness a CAGR of 18.75% during 2023-2028 to reach USD 2292.16 million in 2028.

1. Chemical Industry

In the chemical industry, flexitanks are increasingly used for transporting non-hazardous chemicals and liquid raw materials. Their ability to accommodate various types of chemicals, including those with different viscosities and temperatures, makes them a valuable asset. Flexitanks help streamline logistics by reducing the need for expensive and specialized equipment. They also offer enhanced protection against contamination and spillage, as the liquid is contained within a sealed, single-use bladder. This contributes to safer handling and reduces cleanup and disposal costs.

2. Food and Beverage Sector

The food and beverage industry benefits significantly from the use of flexitanks. These containers are ideal for transporting bulk liquids such as fruit juices, wines, vegetable oils, and dairy products. Flexitanks ensure the preservation of product quality during transit by providing a clean, airtight environment. For example, the use of flexitanks for transporting wine helps maintain its flavor and prevent oxidation. Their flexibility allows for easy adaptation to different product types and volumes, making them an attractive option for producers and distributors looking to optimize their supply chains.

3. Pharmaceutical Industry

In the pharmaceutical sector, flexitanks are utilized for transporting liquid pharmaceuticals, including bulk solutions and intermediates. The pharmaceutical industry requires stringent hygiene and safety standards, and flexitanks meet these needs by offering contamination-free transport solutions. They are designed to protect sensitive liquids from external contaminants, ensuring that the quality and efficacy of pharmaceutical products are preserved throughout the shipping process.

4. Industrial Liquids

For industrial applications, flexitanks are used to transport various industrial liquids such as lubricants, solvents, and antifreeze. Their ability to handle large volumes efficiently makes them ideal for industries that require bulk liquid shipments. Flexitanks offer a cost-effective alternative to traditional methods, reducing the need for complex logistics and storage solutions.

5. Agricultural Products

Flexitanks are also gaining traction in the agricultural sector for transporting liquid fertilizers and pesticides. Their design accommodates the varying densities and chemical properties of these products, providing a reliable and economical means of bulk transport. The flexibility and ease of use of flexitanks streamline the logistics process, making them a preferred choice for agricultural suppliers and distributors.

6. Emerging Applications

As industries continue to explore new ways to utilize flexitanks, innovative applications are emerging. For example, flexitanks are being used in the transport of renewable energy liquids and specialty chemicals. Their adaptability to different liquid types and transportation needs makes them a valuable tool in diverse sectors.

In conclusion, flexitanks are revolutionizing the transport of liquids across multiple industries, from chemicals and food and beverages to pharmaceuticals and agriculture. Their versatility, cost-effectiveness, and ability to maintain product quality make them an essential component of modern logistics and supply chain management. As industries continue to seek efficient and sustainable transport solutions, the use of flexitanks is set to grow, offering significant benefits across various applications.