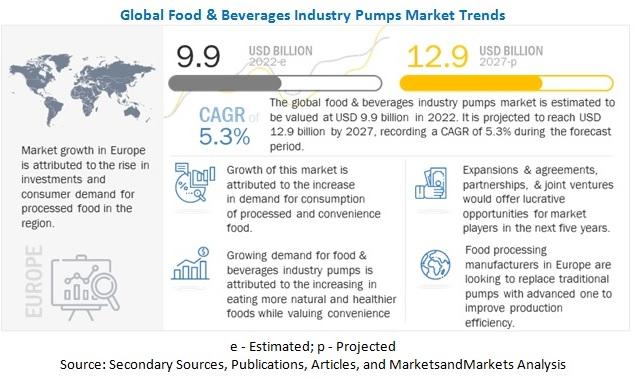

The global food & beverages industry pumps market is estimated to be valued at USD 9.9 billion in 2022. It is projected to reach USD 12.9 billion by 2027, recording a CAGR of 5.3% during the forecast period. Food manufacturers are increasingly focusing their attention on achieving low production costs, rapid turnaround time, and high yield. This is facilitated through incorporating advanced pump technologies. The form in which the food material being processed comes in significantly influences the specific type of pumps employed as some food & beverage industry pumps are better suited for one form over another.

Download PDF brochure: https://www.marketsandmarkets.com/pdfdownloadNew.asp?id=211704387

Increase in demand for meat and poultry in Asia pacific

The consumption and production of meat, particularly in developed countries, remains high. The demand for meat and poultry products is expected to increase in developed countries such as the US, supported by factors such as lower prices of beef, pork, and poultry; increasing focus on enhancing the shelf life, quality, and safety of meat products; and the rising per capita consumption of meat. Meat & poultry-related pumps are expected to offer significant potential due to the growing meat & poultry industry. According to an article on Food Price Outlook, 2018, published by the USDA Economic Research Service, “the year 2018 is expected to exhibit a positive outlook for the pork industry as the number of pork processing facilities is expected to increase, which is expected to drive pork production further.”

Configured to grow at the fastest CAGR during the forecast period.

Configured pumps are sized and configured according to the flow rate and pressure requirements of the system or service. Pumps and pumping system components must be configured according to the needs of the end-use processes. There are several steps involved in the configuration of a pumping system. These include determining the proper pipe size, designing a piping system layout that minimizes pressure drops, and selecting low-loss components. To determine the proper pipe size, designers must balance the initial cost of the pipe against the cost of pushing fluid through it. Larger pipes create less friction loss for a given flow rate; however, larger pipes also have higher material and installation costs.

The 15-30 bar segment is expected to grow at the highest rate

Dosing pumps are small positive displacement pumps that are widely used in the food industry. These pumps are highly valued by convenience food and bakery manufacturing plants for their ability to precisely dose fluids with particles at high flow rates. They can also handle dairy products, sugar, and starches, as well as meat, fish, and animal food, and have a maximum pressure of 20 bar. Pumps in this pressure range are used in the meat & poultry processing industry. Progressive cavity pumps are a type of rotary volumetric pumps that fall into this category. These pumps are commonly found in the food processing industry. They are designed to meet the most stringent hygiene standards and have a consistent flow. Dairy products benefit greatly from this technology (milk, eggs, and yogurts). They are also used in the fruit handling industry and can have maximum pressures of up to 24 bars.

Speak to Analyst: https://www.marketsandmarkets.com/speaktoanalystNew.asp?id=211704387