How Anti-Tear Conveyor Belts Support Sustainable Mining Operations

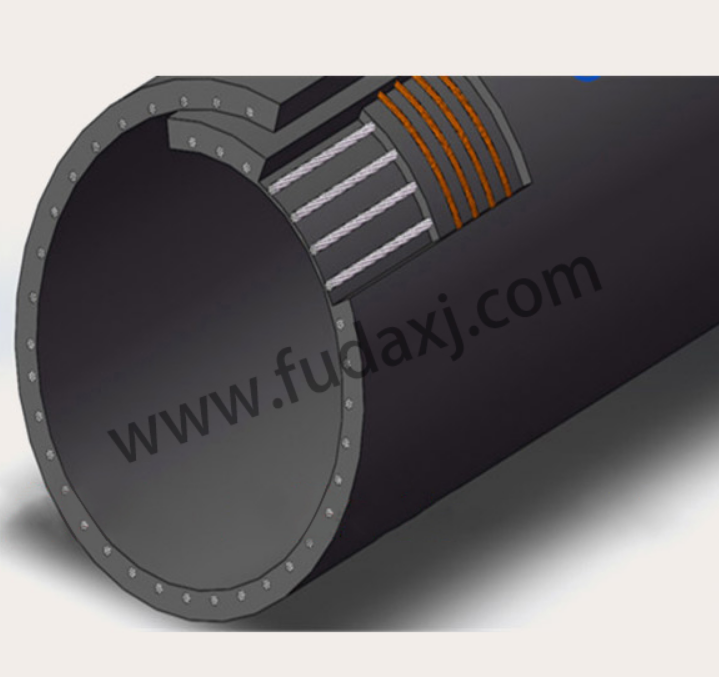

Mining operations demand conveyor systems that can endure extreme conditions, and anti-tear conveyor belts have proven to be a reliable solution. These belts are engineered to handle the rigors of transporting ore, coal, and other minerals without succumbing to the wear and tear that plagues standard belts. Their reinforced construction includes multiple layers of high-tensile fabrics or steel cords, which provide exceptional resistance to rips and punctures.

One of the standout features of anti-tear conveyor belts in mining is their ability to operate over long distances. Many mining sites require material transport across vast areas, and a single tear in the belt can disrupt the entire process. Anti-tear conveyor belts reduce this risk, ensuring consistent material flow and minimizing operational disruptions. Their durability also translates to lower replacement costs, as they outlast conventional belts in harsh environments.

Safety is another critical advantage. Mining environments often involve sharp-edged materials and heavy loads, which can easily damage weaker belts. A torn conveyor belt not only halts production but can also create hazardous conditions for workers. Anti-tear conveyor belts address these concerns by maintaining their integrity even under heavy stress. Some variants are also designed to resist fire and static electricity, further enhancing workplace safety.

Maintenance of anti-tear conveyor belts is relatively straightforward, thanks to their robust design. While regular inspections are still necessary to monitor belt alignment and tension, the frequency of repairs is significantly reduced. Predictive maintenance technologies, such as vibration sensors, can also be integrated to detect potential issues before they escalate.

Sustainability is becoming an increasingly important factor in mining operations, and anti-tear conveyor belts contribute to this goal. Their extended lifespan means fewer belts end up in landfills, and some models are made with eco-friendly materials. Additionally, energy-efficient designs help reduce power consumption during operation.

Anti-tear conveyor belts are a game-changer for the mining industry, offering unmatched durability, safety, and cost-efficiency. Their ability to withstand harsh conditions makes them an invaluable asset for modern mining operations.

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Jeux

- Gardening

- Health

- Domicile

- Literature

- Music

- Networking

- Autre

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness