The Versatile and Efficient Brushed and Brushless DC Electric Motors and Gearmotors

نشر بتاريخ 2024-03-16 05:24:12

0

2كيلو بايت

Introduction:

In today's fast-paced world, the application of electric motors and gearmotors has become widespread across various industries. These motors play a vital role in countless devices and machines, powering them with efficiency and precision. In this article, we will explore the functionalities, advantages, and applications of the brushed DC electric motor, brushed DC electric motor, and brushless DC gearmotor.

The brushed DC electric motor is a reliable and versatile motor that has found its place in various applications. This motor operates by using brushes and a commutator to control the flow of current in the motor's coils. Its simplicity and ease of use make it popular in applications such as electric vehicles, home appliances, power tools, and robotics. The brushed DC motor's ability to operate at different speeds, coupled with its affordability, ensures its relevance in a variety of industries.

2. Brushed DC Electric Motor Applications:

The brushed DC motor's ability to provide high torque and consistent performance makes it an ideal choice for numerous applications. It is commonly utilized in electric vehicles, enabling efficient propulsion and control. Additionally, it can be found in kitchen appliances like blenders, mixers, and juicers, providing reliable power for their operations. The brushed DC motor is extensively used in power tools, including drills, saws, and sanders, facilitating effortless operation. Moreover, in robotics, these motors enable precise and controlled movements for various tasks.

3. Brushed DC Electric Motor Advantages:

While advancements in technology have introduced newer motors, the brushed DC motor still holds several advantages. Its durability and robustness make it an good choice for applications that demand long-lasting performance. It can withstand high temperatures and operate in harsh environments, ensuring reliability in critical conditions. The brushed DC motor's simplicity and cost-effectiveness make it an attractive option for both large-scale industrial applications and smaller consumer products.

4. Brushless DC Gearmotor:

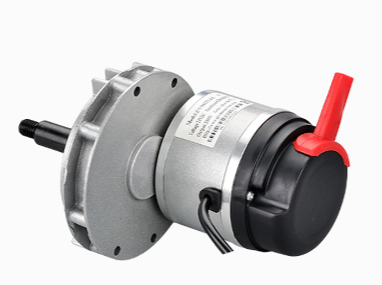

The brushless DC gearmotor combines the advantages of brushless DC motors and the benefits of gearing systems. This motor operates using electronic commutation instead of brushes and commutators. By eliminating physical contact, the brushless DC gearmotor offers increased efficiency, reduced maintenance, and enhanced overall performance. The gear system further amplifies the motor's torque output, making it suitable for applications that require precise speed control and high torque.

5. Brushless DC Gearmotor Applications:

The brushless DC gearmotor's ability to provide efficient and precise power transfer finds extensive use across various industries. In automotive applications, it contributes to the smooth operation of windshield wipers, power windows, and seat adjustments. The brushless DC gearmotor is also utilized in medical equipment, such as surgical devices, where precise and controlled movements are imperative. Additionally, it finds applications in robotics, industrial automation, and aerospace systems, where high performance and reliability are crucial.

Conclusion:

The brushed DC electric motor, brushed DC electric motor, and brushless DC gearmotor are essential components that enable the efficient functioning of numerous devices and machines. Their versatility, reliability, and cost-effectiveness make them indispensable in various industries. While each motor has its unique set of advantages, their applications overlap in many areas. As technology continues to evolve, these motors will continue to play a crucial role in powering innovations across the globe.

البحث

إعلان مُمول

إعلان مُمول

الأقسام

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- الألعاب

- Gardening

- Health

- الرئيسية

- Literature

- Music

- Networking

- أخرى

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness

إقرأ المزيد

!!~!!~~Film!!Alina Amir leak video real or fake Xvideo bf x xVideo & video HD gba

CLICK THIS L!NKK 🔴📱👉...

[--]- tanu rawat video original video link tanu rawat new video viral on social media x now [6x9u4o9] utz

🌐 CLICK HERE 🟢==►► WATCH NOW

🔴 CLICK HERE 🌐==►► Download Now...

Chandigarh to Panipat Cab

Book Chandigarh to Panipat cab online at best price. CabBazar provides car rental services for...

!#[!@X!] El Siri Viral Video Leaked Official Tutorial Leaks on Twitter odb

CLICK THIS L!NKK 🔴📱👉...

Caraway Seeds Market Insights: Health Trends and Consumer Preferences

Caraway Seeds Market is driven by shifting dietary preferences and growing consumer awareness,...