The battery electrode coating market has emerged as a crucial segment in the growing battery industry, driven by the increasing demand for energy storage solutions across various sectors, including electric vehicles (EVs), renewable energy storage, and consumer electronics. The market is influenced by a range of factors that impact both the technology and the demand for battery electrode coatings. These factors span from technological advancements to regulatory standards and market trends. Here’s a deeper look at the key elements impacting the battery electrode coating market.

Technological Advancements in Coating Materials

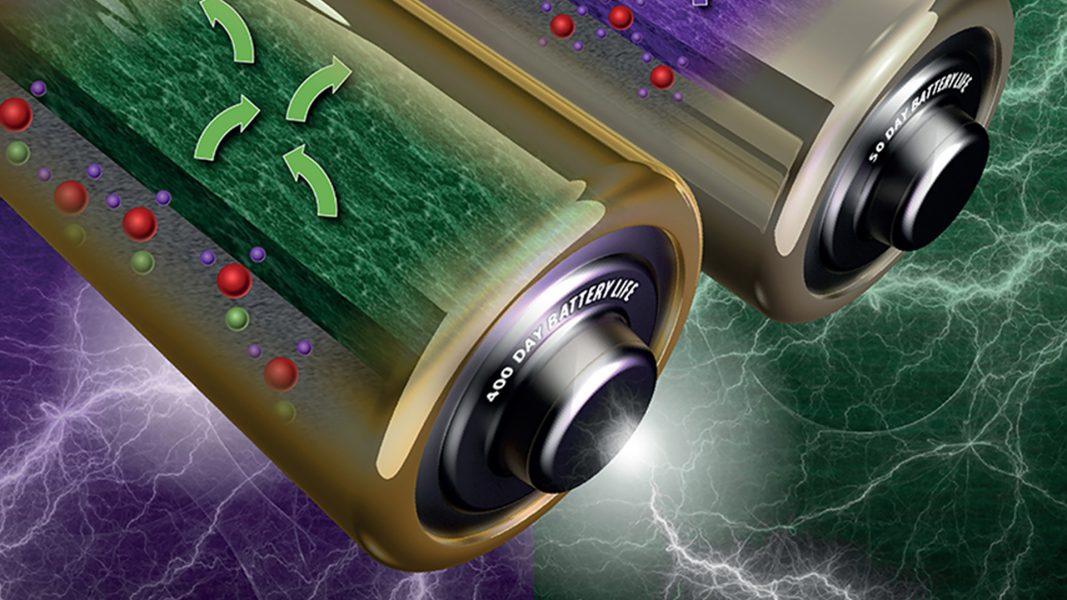

The development of high-performance coating materials plays a pivotal role in driving the growth of the battery electrode coating market. For instance, advancements in the composition of coatings, such as the introduction of more durable and conductive materials, have resulted in batteries that offer enhanced efficiency and longevity. The shift from conventional materials to advanced coatings, such as those involving graphene or other nanomaterials, has drastically improved the overall performance of batteries, thereby increasing the demand for advanced electrode coatings.

Battery manufacturers are constantly exploring new ways to improve charge-discharge cycles, increase energy density, and reduce overall costs. These improvements are made possible by innovations in electrode coatings, which ensure that electrodes remain stable and efficient throughout the battery’s life cycle. The rise of solid-state batteries, which require unique coating solutions, also adds to the dynamic nature of this market.

Growing Demand for Electric Vehicles

The global push towards sustainability and the adoption of electric vehicles (EVs) is a primary driver of the battery electrode coating market. EVs rely heavily on high-performance lithium-ion batteries, which in turn require high-quality electrode coatings to maintain optimal performance and longevity. As governments worldwide introduce stringent emissions regulations and offer incentives for EV adoption, the need for efficient and reliable batteries becomes even more pressing.

As the EV market grows, the demand for electric vehicle batteries is expected to rise substantially. This growth, in turn, is expected to boost the demand for advanced electrode coatings that can improve the battery’s efficiency, extend its life, and reduce the overall cost of EV production. This trend is further supported by the development of ultra-fast charging technologies and longer-range batteries, which require specialized coatings to ensure the batteries meet these advanced requirements.

Environmental Regulations and Sustainability Trends

Environmental concerns and sustainability have become a significant focus in the energy and automotive sectors. The battery electrode coating market is no exception, as manufacturers are increasingly required to comply with environmental regulations concerning the materials used in battery production. There is a growing demand for eco-friendly, non-toxic, and recyclable coating materials.

Governments around the world are also offering incentives for the adoption of sustainable technologies, encouraging battery manufacturers to adopt greener production methods. The drive toward sustainability is pushing the development of coatings that are both environmentally friendly and high-performance. Moreover, advancements in recycling technologies are prompting manufacturers to create coatings that facilitate easier recycling of battery components at the end of the product’s life cycle.

Cost Reduction Pressures

Another key factor influencing the battery electrode coating market is the pressure to reduce the overall cost of battery production. As the demand for batteries increases, particularly in sectors such as EVs and consumer electronics, the need to lower production costs becomes even more critical. Coating materials often represent a significant portion of the overall cost of battery production. To remain competitive, manufacturers are focused on developing coatings that provide superior performance while simultaneously lowering costs.

The economies of scale that come with increasing production volumes, alongside advances in manufacturing technologies, are expected to drive down the cost of high-performance coatings. The use of more affordable raw materials without compromising on performance or quality is another approach being explored to make electrode coatings more cost-effective. As the market for energy storage continues to expand, cost-efficient solutions are likely to become a key competitive differentiator.

Global Supply Chain Dynamics

The global supply chain for battery materials is a complex and often volatile system. Fluctuations in the availability and cost of raw materials, including those used in electrode coatings, can have a significant impact on the market. For example, lithium, cobalt, and nickel are essential raw materials for batteries, and any disruption in their supply can affect the production of both batteries and electrode coatings.

In recent years, geopolitical tensions and disruptions in the global supply chain have highlighted the vulnerability of the battery industry to external factors. To mitigate these risks, battery manufacturers are increasingly looking for alternative materials and solutions. Innovations in electrode coating technology, including coatings that use less critical raw materials, are becoming more common as manufacturers seek to reduce their reliance on unstable supply chains.

Conclusion

The battery electrode coating market is shaped by various factors, ranging from technological advancements to regulatory requirements and market dynamics. With the rapid growth of electric vehicles, renewable energy, and other applications that require efficient energy storage solutions, the demand for high-quality electrode coatings is poised to increase. As manufacturers focus on sustainability, cost reduction, and improving battery performance, the market for battery electrode coatings is expected to see continued growth. Innovation, supply chain management, and regulatory compliance will remain pivotal in driving the future of the battery electrode coating market.