Ultrasonic Testing Market Poised for Significant Growth: Insights into Market Dynamics, Segmentation, and Regional Analysis

The Ultrasonic Testing Market is on a trajectory of substantial growth, driven by technological advancements, increasing demand across various industries, and the imperative for stringent quality control measures. This press release delves into the market's definition, growth drivers, opportunities, segmentation, country-level analyses focusing on the USA and Germany, competitive landscape, and concludes with key takeaways.

Click here for free sample + related graphs of the report @https://www.maximizemarketresearch.com/request-sample/94505/

Market Definition and Estimation

Ultrasonic testing (UT) is a non-destructive testing (NDT) technique that employs high-frequency sound waves to detect internal flaws, measure material thickness, and evaluate material properties. This method is pivotal in ensuring the integrity and safety of components across industries such as oil & gas, aerospace, automotive, manufacturing, marine, power generation, and government infrastructure.

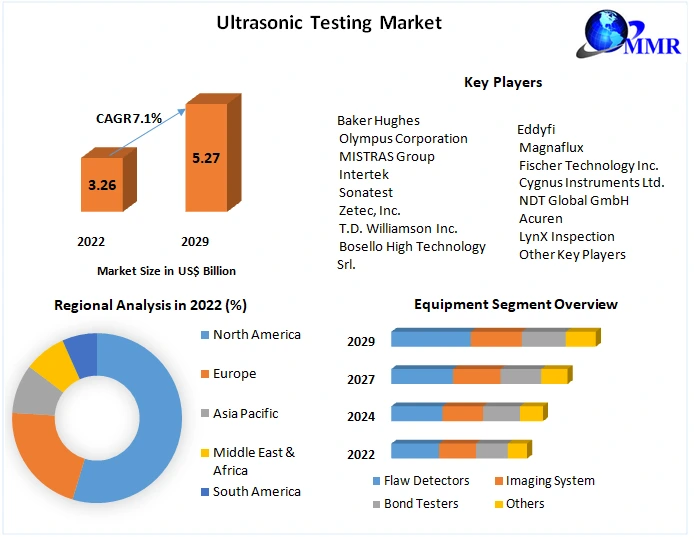

According to recent market analyses, the ultrasonic testing market was valued at approximately USD 2.92 billion in 2024 and is projected to reach USD 4.60 billion by 2029, growing at a compound annual growth rate (CAGR) of 9.5% during the forecast period.

Market Growth Drivers and Opportunities

Several factors are propelling the growth of the ultrasonic testing market:

-

Technological Advancements: Innovations such as phased array ultrasonic testing (PAUT) and time-of-flight diffraction (TOFD) have enhanced the accuracy and efficiency of inspections, making UT more appealing to various industries.

-

Stringent Safety Regulations: Regulatory bodies worldwide mandate rigorous testing protocols to ensure public safety and environmental protection, thereby driving the adoption of UT techniques.

-

Aging Infrastructure: The need to assess and maintain aging infrastructure, particularly in developed nations, necessitates regular inspections, bolstering the demand for UT services.

-

Integration with Industry 4.0: The rise of automation and digitalization in manufacturing processes has led to the incorporation of UT into predictive maintenance strategies, offering opportunities for market expansion.

Segmentation Analysis

The ultrasonic testing market can be segmented based on type, equipment, service type, vertical, and region.

By Type:

-

Phased Array Ultrasonic Testing (PAUT): Utilizes multiple elements to steer and focus the ultrasonic beam, allowing for comprehensive inspections and detailed imaging.

-

Time-of-Flight Diffraction (TOFD): Employs diffraction techniques to detect and size cracks with high precision, commonly used in weld inspections.

-

Immersion Testing: Involves submerging the test object and transducer in a liquid medium, facilitating consistent coupling and detailed scanning, often applied in complex geometries.

-

Guided Wave Testing: Uses low-frequency ultrasonic waves to inspect long sections of pipelines or structures from a single test location, enabling the detection of corrosion or other defects over extended distances.

-

Acoustography: A real-time ultrasonic imaging technique that captures full-field images of internal features, useful in composite material inspections.

By Equipment:

-

Flaw Detectors: Devices designed to identify and characterize defects within materials, essential for quality assurance in manufacturing processes.

-

Thickness Gauges: Instruments that measure material thickness, crucial for assessing corrosion and erosion in pipelines and structural components.

-

Transducers & Probes: Key components that emit and receive ultrasonic waves, tailored for specific applications and material types.

-

Industrial Scanners: Automated systems that facilitate large-scale inspections with high precision, often integrated into production lines.

-

Tube Inspection Systems: Specialized equipment for evaluating the integrity of tubes and pipes, commonly used in power generation and chemical industries.

-

Bond Testers: Assess the quality of bonds in composite materials or adhesively bonded structures, critical in aerospace and automotive sectors.

-

Imaging Systems: Advanced systems that provide visual representations of internal structures, aiding in the interpretation of ultrasonic data.

By Service Type:

-

Inspection Services: Comprehensive examination of components and structures to identify defects, ensuring compliance with safety standards.

-

Equipment Rental Services: Provision of UT equipment on a rental basis, offering flexibility for companies with varying inspection needs.

-

Calibration Services: Ensuring that UT equipment operates within specified parameters, maintaining accuracy and reliability of measurements.

-

Training Services: Educating personnel on UT techniques and equipment operation, essential for maintaining a skilled workforce.

By Vertical:

-

Manufacturing: Ensuring the quality of products and components during production processes, preventing defects and failures.

-

Oil & Gas: Inspecting pipelines, storage tanks, and offshore platforms to detect corrosion, cracks, and other defects that could lead to leaks or failures.

-

Aerospace: Evaluating aircraft components for structural integrity, crucial for flight safety and compliance with aviation standards.

-

Government & Infrastructure: Assessing public infrastructure such as bridges and buildings to ensure safety and longevity.

-

Power Generation: Monitoring turbines, boilers, and other critical components in power plants to prevent unplanned outages and maintain efficiency.

-

Automotive: Testing vehicle components for defects that could compromise performance or safety, supporting quality control in manufacturing.

-

Marine: Inspecting ship hulls and offshore structures for corrosion and structural integrity, vital for maritime safety.

Country-Level Analysis

United States:

The USA represents a significant portion of the ultrasonic testing market, driven by its robust industrial base and stringent regulatory environment. The country's emphasis on infrastructure maintenance, particularly in the oil & gas and aerospace sectors, fuels the demand for advanced NDT techniques like UT. Additionally, the integration of UT with emerging technologies aligns with the nation's focus on innovation and safety.

For more information about this report visit: https://www.maximizemarketresearch.com/market-report/global-ultrasonic-testing-market/94505/

Ultrasonic Testing Market, Key Players are:

1. Baker Hughes

2. Olympus Corporation

3. MISTRAS Group

4. Intertek

5. Sonatest

6. Zetec, Inc.

7. T.D. Williamson Inc.

8. Bosello High Technology Srl.

9. Eddyfi

10.Magnaflux

11.Fischer Technology Inc.

12.Cygnus Instruments Ltd.

13.NDT GmbH

14.Acuren

15.LynX Inspection