The Benefits of Mechanical Expand Chucks in High-Speed Manufacturing Lines

The Role of Mechanical Expand Chucks in Modern Manufacturing Systems

In the realm of industrial machinery, precision, durability, and reliability are essential for ensuring smooth operations. This is particularly true in industries that rely on packaging and material handling systems, such as candy production. One key component that plays a crucial role in enhancing manufacturing efficiency and product quality is the Mechanical Expand Chuck. These devices are used in a variety of manufacturing applications, providing the necessary support to secure and handle materials effectively. In this blog, we will explore the importance of Mechanical Expand Chucks and how they benefit production lines in the manufacturing industry, specifically in candy production.

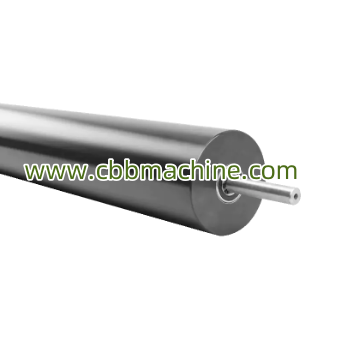

A Mechanical Expand Chuck factory is a device that provides secure and stable holding of material rolls in industrial machines. It functions by expanding and contracting to grip materials, ensuring that the materials remain in place during the production process. These chucks are primarily used to handle large rolls of materials such as films, papers, and textiles, which are crucial in the packaging stages of production. The mechanical design allows for a more reliable hold compared to traditional chucks, which often depend on air pressure or hydraulic systems.

Mechanical Expand Chucks are designed to withstand the rigors of high-volume production, offering durability and consistent performance. They are commonly found in various manufacturing sectors, including the candy industry, where packaging plays a vital role in product presentation and protection.

In candy manufacturing, packaging is an essential part of the process that not only protects the product but also contributes to its overall appearance and market appeal. The packaging process requires careful handling of materials such as film or foil that encase the candy, making it crucial to use reliable equipment to manage these materials. Here’s why Mechanical Expand Chucks are so valuable in this context:

1. Stability and Precision in Handling Materials

One of the primary advantages of Mechanical Expand Chucks is their ability to provide stable and precise control over the packaging material. By securely holding materials, such as film rolls, the chuck ensures that the material is unspooled smoothly during packaging. This precision reduces the likelihood of misalignment, wrinkles, or product defects, leading to consistent packaging quality.

2. Enhanced Operational Efficiency

Mechanical Expand Chucks can significantly improve the efficiency of manufacturing processes. By securing materials properly, they prevent common issues such as material slippage or tangling. This reduces downtime and minimizes the need for manual adjustments. As a result, production lines can run more efficiently, leading to higher throughput and reduced labor costs.

3. Durability and Low Maintenance

High-quality Mechanical Expand Chucks are built to last. These devices are made from robust materials that can endure the constant rotation and high-speed operations typically found in candy manufacturing lines. They are designed to handle large rolls of packaging material without showing signs of wear and tear. This durability ensures that manufacturers can avoid frequent repairs or replacements, which can disrupt production schedules.

4. Versatility for Various Packaging Materials

Candy production often involves different types of packaging materials, from thin films to heavier foils. Mechanical Expand Chucks are adaptable and can handle a wide range of materials. Their versatility makes them suitable for different packaging requirements, allowing manufacturers to switch materials without needing to replace or adjust the chuck.

Choosing the Right Mechanical Expand Chuck for Your Production Line

When selecting a Mechanical Expand Chuck for your production line, several factors must be considered to ensure compatibility and optimal performance. Here are some essential considerations:

1. Material Size and Weight

The size and weight of the material rolls you plan to use will determine the type of chuck you need. For larger, heavier rolls, you’ll need a chuck that can support the weight without compromising the stability of the material during the production process. Be sure to choose a chuck with the appropriate load capacity.

2. Adjustability

If your candy manufacturing line uses various sizes of packaging materials, it’s essential to choose a chuck that is adjustable. This will allow for quick and easy changes between different materials without needing to stop the production line for long periods.

3. Ease of Maintenance

Even the most durable Mechanical Expand Chucks require some level of maintenance to ensure they continue functioning properly. Look for chucks that are designed with ease of maintenance in mind. Features such as accessible components, simple cleaning procedures, and replaceable parts can make maintenance tasks quicker and less costly.

4. Integration with Existing Equipment

When selecting a chuck, ensure it is compatible with your current candy manufacturing equipment. The chuck should easily integrate into the existing setup, whether it is for packaging, material handling, or other applications. A proper fit will help streamline operations and reduce the time spent on installation and adjustments.

How to Implement Mechanical Expand Chucks in Your Production Line

Integrating Mechanical Expand Chucks into your candy production line is generally a straightforward process, particularly if your equipment is already designed to accommodate such devices. However, it’s essential to work with professionals who can help ensure that the chuck is properly installed and calibrated. This will help you maximize its benefits and ensure that your production line runs smoothly.

Regular inspections are necessary to keep the chucks in good working condition. Over time, the springs or mechanical components may require adjustment or replacement. Routine maintenance ensures that your chuck continues to perform at its best, keeping your packaging processes efficient and reliable.

Conclusion

Mechanical Expand Chucks are indispensable tools in the candy manufacturing industry, offering precise control over material handling, enhancing packaging efficiency, and reducing downtime. Their durability and versatility make them ideal for use in high-volume production environments where speed and accuracy are essential. By choosing the right Mechanical Expand Chuck for your needs and ensuring proper maintenance, manufacturers can significantly improve the efficiency of their production lines.

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Spiele

- Gardening

- Health

- Startseite

- Literature

- Music

- Networking

- Andere

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness