The Resilience of Board to Board Power Connectors Under Extreme Heat Conditions

In the realm of electronic components, the Board to Board Power Connectors are integral for establishing secure and efficient power transfer between circuit boards. Their performance under various environmental conditions, especially high temperatures, is a critical consideration for engineers and designers. This article delves into the challenges faced by Board to Board Power Connectors in high-temperature environments and the measures taken to ensure their reliable operation.

The performance of Board to Board Power Connectors is heavily influenced by temperature fluctuations. As the temperature rises, the materials used in the connectors can expand, which may lead to mechanical stress and potential failure. The plastic housings and insulating materials within Board to Board Power Connectors are particularly susceptible to these temperature-induced changes. Moreover, the metal contacts can experience thermal expansion, which may cause misalignments or increased resistance, affecting the overall efficiency of the power transfer.

To assess the performance of Board to Board Power Connectors in high-temperature conditions, several factors must be considered. Firstly, the material composition of the connectors plays a significant role. Connectors made from high-temperature-resistant plastics such as polyphenylene sulfide (PPS) or liquid crystal polymer (LCP) are better suited for high-temperature environments compared to those made from standard thermoplastics. These materials maintain their mechanical properties and dimensional stability even when exposed to prolonged high temperatures.

Secondly, the design of the Board to Board Power Connectors is crucial. Connectors with a robust design that incorporates heat sinks or thermal dissipation channels can manage heat more effectively, thereby reducing the risk of overheating. Additionally, the use of gold-plated contacts can improve conductivity and reduce the risk of oxidation at high temperatures, which is a common issue with lesser metals.

Another aspect to consider is the impact of temperature on the electrical performance of Board to Board Power Connectors. High temperatures can cause an increase in contact resistance, leading to power loss and potential overheating. Connectors manufacturers often test their products under simulated high-temperature conditions to ensure that the connectors can handle the thermal stress without significant degradation in performance.

Environmental factors, such as humidity and exposure to chemicals, can also exacerbate the effects of high temperatures on Board to Board Power Connectors. Therefore, it is essential to select connectors with appropriate sealing and protection ratings to safeguard against moisture and chemical-induced corrosion.

In conclusion, the performance of Board to Board Power Connectors in high-temperature environments is a complex issue that requires a multifaceted approach. By selecting the right materials, designing the connectors for heat management, and considering the environmental protection, manufacturers can produce Board to Board Power Connectors that meet the stringent demands of high-temperature applications. The ongoing research and development in this field aim to push the boundaries of what is possible, ensuring that these connectors remain a reliable choice for power transmission in the most challenging conditions.

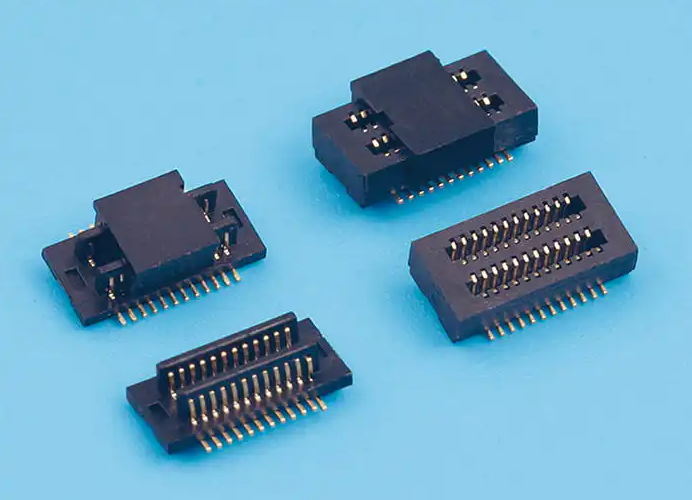

1、CKT: 2*5Pin to 2*40Pin

2、Current rating: 0.5A AC/DC

3、Voltage rating(max): 100V, AC/DC

4、Working Temperature: -25C~ +85C,

(Including temperature rise in applying electrical current)

5、Contact resistance: value s20mΩ

After environmental testing s40mΩ

6、Insulation resistance: 21000MΩ

7、Withstand voltage: 200VAC(rms)

8、Applicable PCB board thickness: 1.6mm to 2.0mm

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Games

- Gardening

- Health

- Home

- Literature

- Music

- Networking

- Other

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness