Industrial IoT and Digital Twins Transforming Maintenance

AI and IIoT in Smart Manufacturing: The Role of Predictive Maintenance

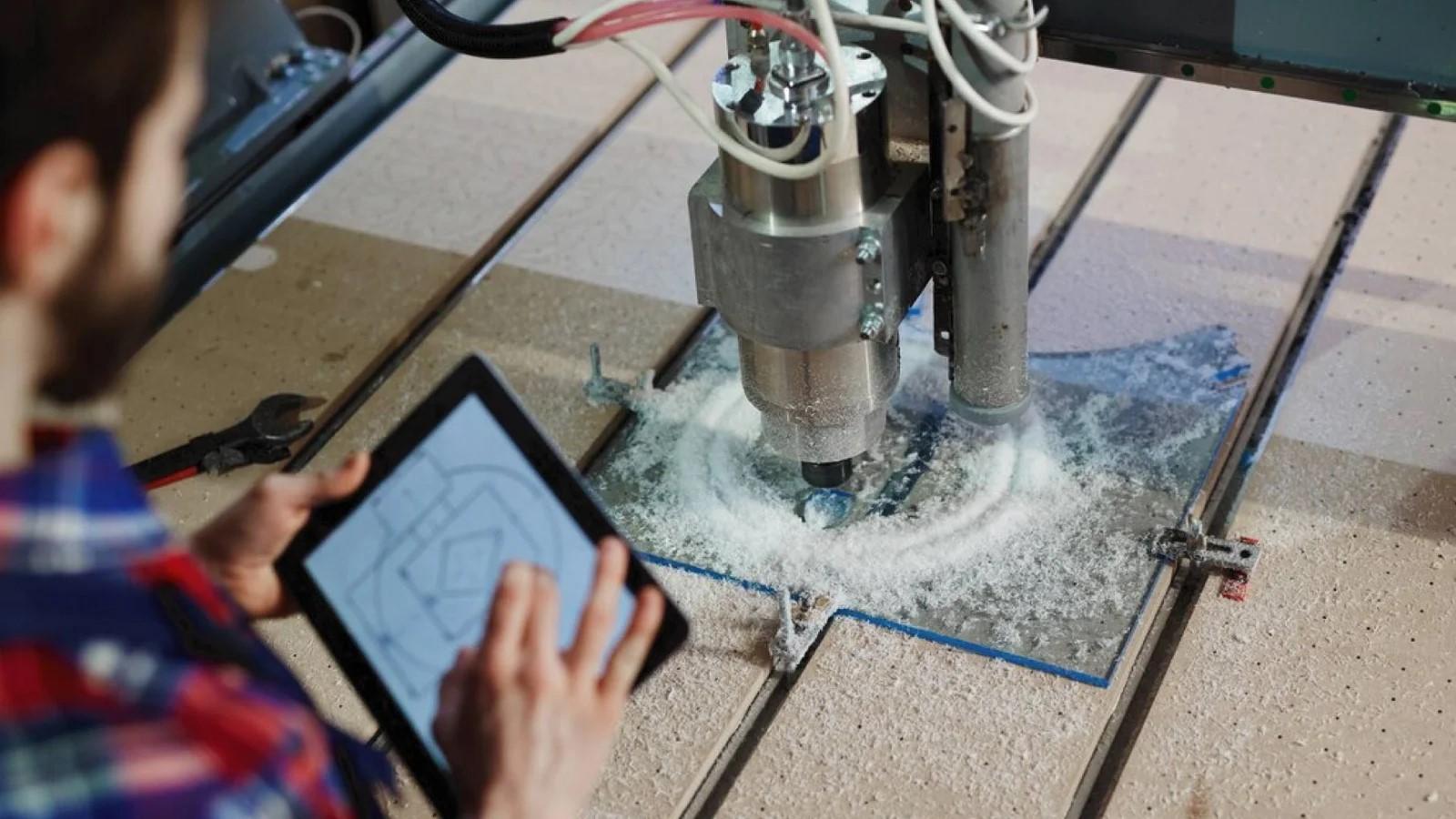

The integration of Artificial Intelligence (AI) and the Industrial Internet of Things (IIoT) is transforming the manufacturing industry. One of the most significant advancements enabled by these technologies is predictive maintenance, which enhances operational efficiency, reduces downtime, and optimizes resource utilization. By leveraging AI-driven analytics and IIoT connectivity, manufacturers can detect potential equipment failures before they occur, improving productivity and cost-effectiveness.

Table of Contents

-

Introduction to Predictive Maintenance

-

How AI and IIoT Enable Predictive Maintenance

-

Key Benefits of Predictive Maintenance

-

Applications in Smart Manufacturing

-

Future of Predictive Maintenance in Industry

-

Conclusion

Introduction to Predictive Maintenance

Predictive maintenance is an AI-driven strategy that uses real-time data and machine learning algorithms to anticipate equipment failures before they happen. Unlike traditional reactive or scheduled maintenance, predictive maintenance leverages IIoT sensors and AI-powered analytics to continuously monitor machinery, ensuring timely interventions and minimizing disruptions.

How AI and IIoT Enable Predictive Maintenance

AI and IIoT work together to facilitate predictive maintenance by collecting and analyzing vast amounts of sensor data. IIoT devices embedded in industrial equipment transmit performance metrics, which AI algorithms process to detect patterns, anomalies, and potential failures. Machine learning models improve over time, offering more accurate predictions and enabling proactive decision-making.

Key Benefits of Predictive Maintenance

-

Reduced Downtime: By predicting failures, manufacturers can schedule maintenance only when necessary, preventing unplanned stoppages.

-

Cost Savings: Timely interventions lower repair costs and extend equipment lifespan.

-

Improved Safety: Early detection of malfunctions enhances workplace safety and reduces the risk of catastrophic failures.

-

Increased Efficiency: Continuous monitoring ensures optimal equipment performance, boosting overall productivity.

Applications in Smart Manufacturing

Predictive maintenance is widely adopted across various manufacturing sectors, including automotive, aerospace, and pharmaceuticals. Smart factories utilize AI-driven insights to streamline operations, ensuring machinery remains functional and efficient. Additionally, predictive analytics aids in supply chain management by forecasting equipment needs and reducing waste.

Future of Predictive Maintenance in Industry

As AI and IIoT technologies continue to evolve, predictive maintenance will become even more sophisticated. Advancements in edge computing, digital twins, and 5G connectivity will enhance real-time data processing, enabling even more precise and automated maintenance strategies. Manufacturers investing in predictive maintenance today will gain a competitive edge in the future of smart manufacturing.

For More Info: https://bi-journal.com/ai-iiot-smart-manufacturing/

Conclusion

Predictive maintenance is revolutionizing smart manufacturing by enhancing efficiency, reducing costs, and improving equipment reliability. With AI and IIoT driving continuous advancements, the adoption of predictive maintenance strategies will become an essential component of modern industrial operations. By leveraging real-time data and intelligent analytics, manufacturers can optimize their processes, minimize downtime, and achieve long-term sustainability in an increasingly digitalized world.

Related News/ Articles Link:

https://hrtechcube.com/top-5-hr-certification-programs-in-2024/

https://hrtechcube.com/hr-in-developing-a-future-ready-workforce/

https://hrtechcube.com/the-importance-of-mental-health-policies/

https://hrtechcube.com/the-hr-industry-with-blockchain-technology/

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Games

- Gardening

- Health

- Home

- Literature

- Music

- Networking

- Other

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness