Introduction

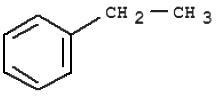

Ethylbenzene is a vital petrochemical primarily used as a precursor in the production of styrene, a key component in various plastics and resins. Styrene is widely utilized in industries such as packaging, construction, automotive, and electronics. As global demand for styrene-based products continues to rise, the ethylbenzene market plays a critical role in supporting industrial growth. This article explores the significance of ethylbenzene in styrene production, its manufacturing process, and market trends.

The Role of Ethylbenzene in Styrene Production

Ethylbenzene serves as the fundamental raw material for styrene production. The transformation of ethylbenzene into styrene occurs through a process known as catalytic dehydrogenation, where hydrogen is removed from ethylbenzene under controlled conditions to form styrene monomer. This reaction is typically facilitated by metal oxide catalysts and requires high temperatures to ensure efficiency.

Key Steps in the Production Process:

-

Ethylbenzene Synthesis: Ethylbenzene is produced through the alkylation of benzene with ethylene in the presence of a catalyst.

-

Catalytic Dehydrogenation: Ethylbenzene undergoes dehydrogenation in the presence of steam and an iron-based catalyst to yield styrene and hydrogen gas.

-

Purification and Separation: The resulting styrene is separated and purified for industrial applications, while by-products such as hydrogen may be utilized in other chemical processes.

Market Trends Driving Ethylbenzene Demand

Several factors influence the demand for ethylbenzene, primarily due to its extensive use in styrene production.

1. Increasing Demand for Polystyrene and ABS Plastics

Styrene-derived polymers such as polystyrene and acrylonitrile-butadiene-styrene (ABS) are essential in the production of packaging materials, automotive components, and household goods. The rising need for lightweight and cost-effective materials is fueling ethylbenzene consumption.

2. Expansion of the Construction and Automotive Sectors

Styrene-based materials are widely used in insulation, piping, and structural components. The growth of construction projects worldwide, along with advancements in the automotive industry focused on lightweight materials for fuel efficiency, is driving ethylbenzene market expansion.

3. Technological Advancements in Petrochemical Manufacturing

Innovations in production technology, including energy-efficient catalysts and optimized dehydrogenation processes, are improving ethylbenzene yield and reducing environmental impact. These advancements enhance the sustainability and cost-effectiveness of styrene production.

4. Emerging Sustainability Trends and Challenges

While ethylbenzene is integral to styrene production, the market faces challenges related to environmental regulations and the push for bio-based alternatives. Companies are exploring greener production methods and recycling initiatives to mitigate the environmental impact of styrene-based plastics.

Future Outlook

The ethylbenzene market is expected to experience steady growth due to the rising demand for styrene-based products across multiple industries. However, sustainability concerns and regulatory changes may shape future market dynamics. Companies that focus on process efficiency, eco-friendly innovations, and strategic expansions will be better positioned to navigate the evolving landscape.

Conclusion

Ethylbenzene plays an indispensable role in styrene production, serving as the primary raw material for a wide range of industrial applications. As demand for styrene-based materials continues to grow, the ethylbenzene market will remain a key component of the global petrochemical industry. Addressing environmental challenges and embracing sustainable practices will be essential for long-term market success.