Understanding Belt Filter Technology: A Comprehensive Guide

Introduction to Belt Filter Technology

Overview of Belt Filters

In the realm of solid liquid separation processes belt filters play a role as they employ a moving belt to separate solids, from liquids effectively and are highly valued in different industries for this purpose.

History and Evolution of Belt Filters

The idea of belt filtration has developed greatly since it was first introduced. Initially simple designs were used for filtering purposes. As time passed and materials and engineering improved advanced belt filters were created to tackle intricate and challenging tasks. This progress was fueled by the demand, for increased efficiency enhanced durability and flexibility to meet industrial needs.

Importance and Applications of Belt Filters

In sectors like mining and chemical processing, to water treatment and food production industries; belt filters play a significant role by efficiently separating solids from liquids to ensure product quality and process efficiency are maintained at high standards.

Components and Design of Belt Filters

Main Components of a Belt Filter

Filtration Cloth

The filter cloth plays a role in how well the separation process works, serving as a barrier, for solid particles while allowing liquid to flow through it smoothly.

Rollers and Belts

Rollers play a role in guiding the belt as it moves through the filter system smoothly and efficiently by keeping it aligned and under tension to ensure proper operation. The belts are specifically engineered to endure types of operational challenges such as pressure and exposure, to chemicals.

Drive System

The drive system powers the movement of the belt across rollers. It typically consists of motors and gears that provide consistent speed and torque necessary for efficient filtration. A reliable drive system is essential for maintaining optimal performance over extended periods.

Types of Belt Filter Designs

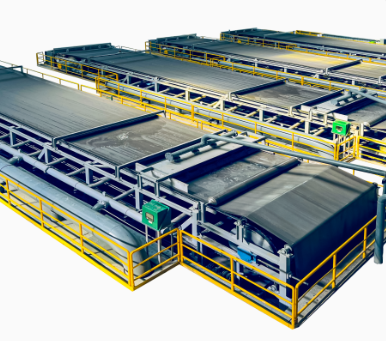

Horizontal Belt Filters

One of the widely used designs, in industry is the horizontal belt filters which work in a horizontal position leveraging gravity to aid in separating materials efficiently and effectively perform well for tasks that demand consistent operation with a high volume of throughput.

Vertical Belt Filters

Vertical belt filters vary in their orientation by positioning the belt instead of horizontally; this setup is useful in situations with limited space or when particular flow patterns are needed for optimal performance purposes.This arrangement provides advantages like a smaller footprint and clearer filtrate thanks, to better drainage efficiency.

Working Principles of Belt Filters

Filtration Process Explained

The belt filters filtration process consists of steps including feeding the slurry onto the belt to create a filter cake through spreading and draining liquid while moving along the belt surface before discharging the dewatered solids after washing or drying if needed.

Key Factors Influencing Efficiency

There are elements that impact the effectiveness of operating a belt filter.

· Filtration Cloth Selection: Choosing an appropriate cloth material impacts both filtration rate and quality.

· Belt Speed: Adjusting speed affects residence time for slurry on the filter surface.

· Pressure Application: Proper pressure ensures optimal separation without damaging equipment.

· Slurry Properties: Characteristics such as particle size distribution influence how effectively solids are captured.

Grasping these elements enables operators to enhance efficiency based on operational requirements.

At the end of this article it is clear that...

Advantages and Limitations of Belt Filters

Benefits of Using Belt Filters

High Throughput Capacity

Belt filters are renowned for their ability to handle large volumes of material efficiently. This high throughput capacity makes them ideal for industries where rapid processing is crucial, such as mining and wastewater treatment. The continuous movement of the belt allows for uninterrupted operation, ensuring that large quantities of slurry can be processed without significant delays. This capability not only enhances productivity but also reduces operational costs by minimizing downtime.

Continuous Operation Capability

Belt filters have a quality in their continuous operation feature that sets them apart from batch processes; it eliminates the need to pause for unloading or cleaning tasks and boosts efficiency significantly as a result of this uninterrupted flow of filtration process which proves particularly advantageous for industries requiring continuous operations as it ensures a smooth material flow, through the system enhancing overall process efficiency and consistency.

Potential Drawbacks and Challenges

While belt filters offer benefits of their accord there are some downsides to consider as well. An issue that may arise is the expense for installation and configuration which could be quite significant depending on the systems complexity and scale. Moreover they need upkeep to maintain peak performance leading to increased operational expenses, in the long run. Dealing with particles poses another challenge; although belt filters work well in numerous scenarios handling very fine particles might necessitate extra precautions to prevent blockages or decreased filtration effectiveness.

Maintenance and Operational Considerations for Belt Filters

Routine Maintenance Practices

To keep belt filters running smoothly and efficiently over time requires upkeep practices such as checking the filtration cloth for damage regularly and making sure that the rollers are correctly positioned and lubricated to prevent issues with the drive system from arising unexpectedly. Additionally important is ensuring that the belts and cloths are kept clean to avoid blockages and maintain filtration efficiency. Creating and following a maintenance plan is key to prolonging the lifespan of the equipment and minimizing unplanned interruptions, in operation.

Troubleshooting Common Issues

Belt filters often encounter problems such as blockages in the filter cloth and issues with belt or roller alignment along with breakdowns in the drive system itself. To address these issues effectively requires operators to examine the affected components for any evident signs of damage or blockages first and foremost. If misalignment is detected during inspection adjustments to belt tension or alignment might be needed for resolution. For problems, within the drive system replacing worn out parts or recalibrating motors may be necessary to guarantee smooth operation.

Future Trends in Belt Filter Technology

Innovations in Design and Materials

The upcoming developments in belt filter technology offer progressions in design and materials improvement ahead of us excitingly! The advancements involve the creation of synthetic materials for filter cloths to boost durability and resilience against chemical exposure effects significantly anticipated in the industry. Moreover the enhancements, in automation technology have the potential to bring forth intelligent systems that can autonomously monitor themselves and fine tune operational settings promptly for enhanced efficiency levels.

Environmental Considerations and Sustainability

With the increasing emphasis in industries on awareness there is a noticeable shift towards enhancing the sustainability of belt filter operations. Measures are being taken to decrease energy usage by implementing efficient drive systems and improving water management during washing procedures. Additionally research is underway to investigate the potential of using materials, for filtration cloths to reduce the environmental footprint post disposal.

When businesses grasp the advantages and obstacles linked to belt filter technology effectively they can make the most of this tool for separating solids and liquids efficiently while getting ready, for upcoming innovations that offer even more effectiveness and eco friendliness.

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Jocuri

- Gardening

- Health

- Home

- Literature

- Music

- Networking

- Alte

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness