Understanding Laminated Glass

Definition and Composition

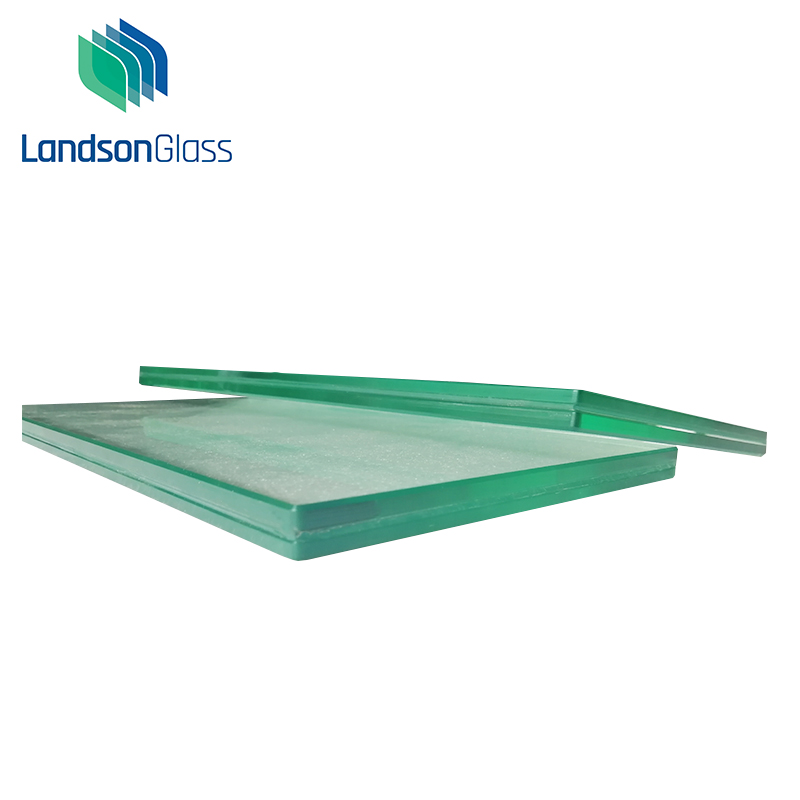

Safety glass known as laminated glass remains intact after breaking due to the layer of polyvinyl butyral (PVB) sandwiched between multiple glass layers during its production process This unique feature enhances safety and security by keeping the glass bonded together when shattered Similar, to laminated glass tempered glass is favored for windows and doors for its superior strength and safety features compared to standard materials Both types of glass prioritize safety as a key characteristic

Historical Background

Laminated glass was first introduced in the 1900s to enhance safety in car windshields by lessening the chance of injuries from shattered glass during collisions.This technology has since. Found utility in diverse sectors due, to its distinctive characteristics.

Key Benefits of Laminated Glass

Safety and Security Features

One of the advantages of laminated glass is its ability to enhance safety through its unique design and structure. The PVB interlayer not keeps the glass intact upon impact but also offers protection against intrusion serving as a reliable deterrent against unauthorized access. This makes it a popular choice, for locations that prioritize security measures. Armored glass and other specialized types of glass are commonly employed in situations that demand levels of security.

Environmental and Health Advantages

Laminated glass offers more than safety benefits. It also has a positive impact on the environment and health aspects as well! The layer within the glass can shield against, up to 99% of UV rays that can cause fading inside spaces while also cutting down on heat transfer that helps save energy in structures. Moreover it helps noise levels by absorbing sound waves making living or working areas more pleasant.

Uses of Laminated Glass in Various Industries

Architectural Applications

Laminated glass is commonly seen in architecture for windows and skylights well as facades and curtain walls because of its strength and attractive look Its often chosen for places prone to hurricanes or requiring high security due to its durability against impacts Decorative features like printed or designed patterns can also be added to laminated structures, for both practical use and aesthetic appeal.

Automotive Industry

The car industry was among the users of laminated glass technology and continues to use it as a common material for windshields because of its capacity to reduce the risks of injuries, in accidents The safety benefits of this technology apply not only to cars but also extend to buses trains and airplanes.

Other Specialized Uses

Specialized industries also utilize glass for a variety of purposes such as constructing aquarium tanks and display cases as well as designing furniture that requires both durability and see through properties.The combination of insulated glass with laminated materials is often done to improve efficiency, in modern eco friendly structures.

Through grasping the structure and varied uses of glass materialize an understanding of its important function in various fields while acknowledging the constant advancements that improve its effectiveness and versatility.

Comparison with Tempered Glass

Differences in Manufacturing Processes

The production methods of glass and tempered glass show notable distinctions in their manufacturing procedures. In the case of laminated glass production involves the step of placing a butyral (PVB) interlayer between two or more layers of glass which are then subjected to heat and pressure to ensure a strong adhesion, between the interlayer and the glass surfaces. On the tempered glass is made by heating standard glass at elevated temperatures followed by quick cooling processes. The process of applying heat to it enhances its durability and results, in it fracturing into dull fragments instead of sharp pieces when broken.

Strength and Durability

Both. Tempered glass provide increased strength compared to standard glass materials but have different durability features.Tempered glass is commonly used for doors and windows as it offers strength and safety than regular materials due to its better impact resistance.Laminated glass on the hand is not as sturdy as tempered glass, against direct impacts but maintains its integrity upon breaking thanks to the PVB interlayer. This characteristic adds value to laminated glass in situations where it is crucial to contain shattered pieces effectively.

Suitability for Different Applications

When deciding between laminated and tempered glass types for uses is primarily based the specific needs of the project at hand. Laminated glass is usually chosen for situations where safety measures like qualities and UV protection are necessary along with ensuring security features are top notch; commonly seen in architectural designs for windows and building exteriors that prioritize these characteristics. On the other hand tempered glass finds its place in applications that require mechanical support and resistance against thermal strains such as in shower enclosures or kitchen appliances, like oven doors or specific furniture pieces.

Innovations and Future Trends in Laminated Glass

Advances in Interlayer Materials

Innovations in the field have been centered around improving the characteristics of interlayer materials utilized in glass products lately. Companies are looking into combinations that enhance stickiness and flexibility while also boosting transparency and safety measures. These progressions are geared towards tuning laminated glass, for particular uses like better soundproofing or increased energy conservation efforts.

Sustainable Practices in Production

"Sustainability is now a priority in the laminated glass sector as industry players strive to minimize their environmental footprint through eco friendly manufacturing methods like using recycled materials and cutting down energy usage in production processes. Moreover there is a growing interest, in incorporating Borosilicate Glass. Renowned for its thermal expansion characteristics. Into laminated products to improve their environmental sustainability."

Through the analysis of manufacturing variations and durability factors alongside the relevance to uses and the progress in interlayer materials technology as well as environmentally friendly methods; it is evident that laminated glass is evolving into a flexible material with vast opportunities, across multiple sectors. Its continuous growth suggests improvements that will broaden its range of applications even further.

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- الألعاب

- Gardening

- Health

- الرئيسية

- Literature

- Music

- Networking

- أخرى

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness