Wet Film Formation Technology: An Effective Means for Material Preparation

In the field of materials science, wet film formation technology is a widely used method for preparing thin film materials. This technique has unique characteristics and advantages, playing an important role in various fields. This article will explore the principles, process flow, and applications of wet film formation technology.

1. Principle of Wet Film Process

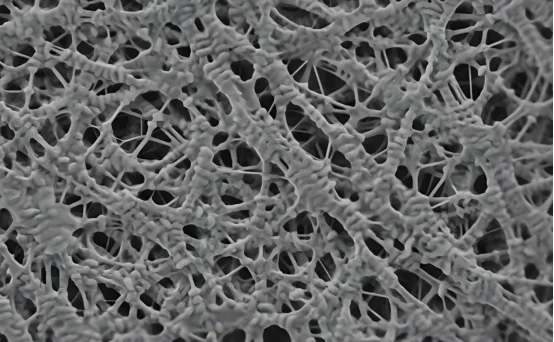

The membrane preparation wet process, also known as thermally induced phase separation (TIPS), primarily involves mixing polymers with high-boiling-point diluents such as wax oil or dioctyl phthalate (DOP) to form a homogeneous solution at elevated temperatures. By lowering the temperature, solid-liquid or liquid-liquid phase separation occurs. After pressing to obtain a membrane, the residual diluents are washed away using volatile substances (such as dichloromethane and trichloroethylene) near the melting point, ultimately producing a polymer microporous membrane.

Wet process diaphragms

The wet process is suitable for producing thinner single-layer polyethylene (PE) membranes and offers superior uniformity in thickness, physical and chemical properties, and mechanical performance compared to dry film formation processes.

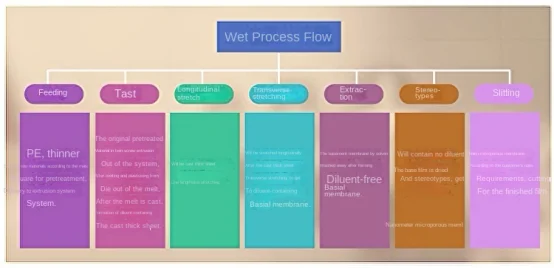

2. Process Flow of Wet Film Technology

Material Feeding: Pre-treated raw materials such as PE (polyethylene) and diluents are transported to the extrusion system according to the formulation. The extrusion system's role is to plasticize and melt the solid materials into a uniformly heated melt for continuous extrusion.

Casting: The pre-treated raw materials are melted in a twin-screw extrusion system and extruded through a die to form a cast sheet containing diluents.

Longitudinal Stretching: The cast sheet is subjected to longitudinal stretching.

Transverse Stretching: The longitudinally stretched cast sheet undergoes transverse stretching to produce a base film containing diluents.

Extraction: The base film is treated with solvents to remove residual diluents, resulting in a base film free of diluents.

Shaping: The diluent-free base film is dried and shaped to obtain a nanoporous membrane.

Cutting: The nanoporous membrane is cut into finished membranes according to customer specifications.

3. Applications of Wet Film Formation Technology

1) Electronics Sector

Wet film formation technology can be used to produce insulation layers and conductive layers in integrated circuits, as well as thin-film transistors in flat panel displays.

2) Energy Sector

This technology can be applied in the fabrication of light-absorbing layers and electrolyte membranes for solar cells, as well as electrode materials for lithium-ion batteries.

3) Environmental Protection Sector

Wet film formation technology is useful for preparing membrane separation materials for wastewater treatment and gas separation membranes.

4) Optical Sector

It is employed in manufacturing various optical devices such as filters, mirrors, and polarizers to achieve specific optical properties.

4. Advantages of Mikrouna's Wet Film Formation Equipment

1. Precise Control: This equipment allows for precise control of various parameters during the wet film formation process, such as slurry concentration, coating speed, and drying temperature, ensuring that the solid-state battery films produced have high consistency and stability.

2. High-Purity Environment: Conducting wet film formation within a glove box effectively prevents moisture, oxygen, and other impurities from affecting film quality, ensuring the performance of solid-state batteries.

3. Versatility: Mikrouna's wet film formation equipment can accommodate different types of solid-state battery materials and process requirements, providing greater flexibility for research and production.

4. Efficient Production: Utilizing automated control technology enables continuous production, increasing efficiency while reducing production costs.

Wet film formation technology has become an important technique in material preparation across multiple fields such as electronics, energy, and environmental protection. With ongoing technological advancements and innovations, wet film formation technology is expected to leverage its unique advantages in more areas, contributing significantly to technological progress and social development.

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Παιχνίδια

- Gardening

- Health

- Κεντρική Σελίδα

- Literature

- Music

- Networking

- άλλο

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness