The Role of Dot Peen Marking in Aerospace Component Traceability

In the aerospace industry, precision and traceability are non-negotiable. Every component, from the smallest bolt to the largest turbine blade, must be meticulously tracked throughout its lifecycle. This is where dot peen marking technology shines. Unlike other marking methods, dot peen marking offers a permanent, high-contrast, and durable solution that meets the stringent requirements of aerospace manufacturing.

Why Dot Peen Marking is Ideal for Aerospace Applications

Permanent Markings for Long-Term Traceability

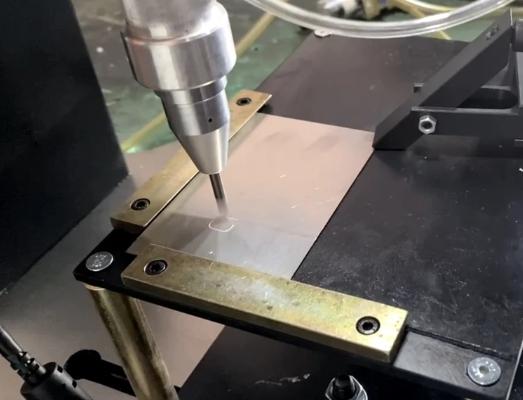

Aerospace components are exposed to extreme conditions, including high temperatures, pressure, and corrosive environments. Dot peen marking uses a pneumatically or electrically driven stylus to create indented marks, ensuring the identification remains legible even after years of use. This permanence is critical for compliance with industry regulations like AS9100.

High Precision on Complex Surfaces

Aerospace parts often have irregular shapes and tight tolerances. Dot peen markers can be programmed to mark curved, angled, or uneven surfaces with pinpoint accuracy, ensuring consistent readability without compromising the integrity of the component.

Non-Thermal Process for Material Integrity

Unlike laser marking, dot peen marking does not generate heat, which is crucial for aerospace materials like titanium and composites. Heat can alter the structural properties of these materials, but dot peen marking leaves the material’s integrity intact.

Cost-Effective and Efficient

For manufacturers, dot peen marking offers a balance of affordability and performance. The machines are relatively low-maintenance and can be integrated into production lines for seamless part identification without slowing down operations.

Real-World Applications in Aerospace

Dot peen markers are used to engrave serial numbers, batch codes, and QR codes on critical components like landing gear, engine parts, and structural elements. These markings enable manufacturers, maintenance teams, and regulators to track each part’s history, ensuring safety and accountability.

Conclusion

In an industry where safety and precision are paramount, dot peen marking provides a reliable and efficient solution for component traceability. Its ability to create durable, high-precision marks on a wide range of materials makes it an indispensable tool in aerospace manufacturing.

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Oyunlar

- Gardening

- Health

- Home

- Literature

- Music

- Networking

- Other

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness