The Vital Role of Mechanical Engineering in Supply Chain Optimization

The integration of engineering machnical supply chain management has transformed industries by enhancing efficiency, reducing costs, and optimizing processes. As global supply chains become increasingly complex, the role of engineering expertise is indispensable in ensuring seamless operations. This article explores how mechanical engineering influences the supply chain, focusing on its critical contributions to logistics, production, and maintenance.

The Intersection of Mechanical Engineering and Supply Chain Management

Mechanical engineering and supply chain management might appear as distinct domains at first glance, but their overlap is undeniable. The synergy between the two ensures the design, manufacturing, and delivery of products align with market demands.

-

Product Design and Development

Mechanical engineers play a pivotal role in the design phase, ensuring that products meet quality standards and are easy to manufacture. Through Computer-Aided Design (CAD) and simulation technologies, engineers can identify potential production bottlenecks before they arise, saving time and resources. -

Efficient Manufacturing Processes

The supply chain heavily relies on efficient production processes, which mechanical engineering innovations can enhance. Automation technologies such as robotics, conveyor systems, and advanced machining tools streamline operations, minimize downtime, and ensure high precision in manufacturing. -

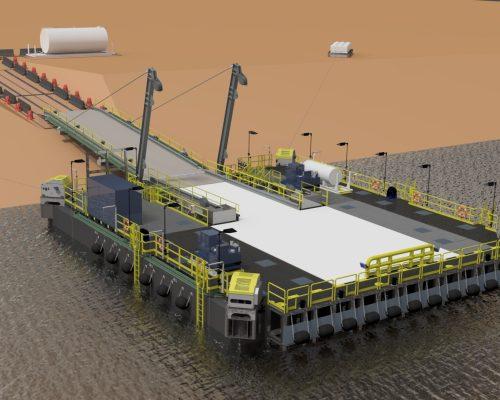

Material Handling and Equipment Optimization

Material handling is a cornerstone of supply chain management. Mechanical engineers design and maintain equipment like forklifts, conveyors, and automated guided vehicles (AGVs) to optimize the movement of goods within warehouses and factories. Proper equipment maintenance, enabled by engineering expertise, reduces delays and equipment failures.

Engineering Innovations in Logistics and Transportation

Logistics and transportation form the backbone of supply chains, and mechanical engineering significantly influences their efficiency. From designing transport vehicles to maintaining fleet systems, engineering innovations drive performance.

Vehicle Design and Fuel Efficiency

Mechanical engineers contribute to designing fuel-efficient transport vehicles, ensuring the movement of goods is cost-effective and environmentally sustainable. Lightweight materials, aerodynamic designs, and hybrid power systems have revolutionized the logistics industry.

Predictive Maintenance in Fleet Management

Predictive maintenance, powered by sensors and data analytics, ensures that transportation fleets operate at optimal capacity. Mechanical engineers develop and implement these systems to reduce breakdowns and improve delivery timelines.

Cold Chain Logistics Solutions

In industries like pharmaceuticals and food, cold chain logistics is crucial. Mechanical engineering innovations in refrigeration systems and insulated transport containers ensure temperature-sensitive products maintain their integrity throughout the supply chain.

Sustainability and Mechanical Engineering in the Supply Chain

Sustainability is a growing priority for supply chain management, and mechanical engineering plays a crucial role in achieving eco-friendly practices.

Energy-Efficient Machinery

Mechanical engineers design energy-efficient machinery for manufacturing and logistics, reducing overall carbon footprints. Energy recovery systems, such as regenerative braking in conveyor belts, are examples of sustainable engineering innovations.

Waste Reduction Strategies

Engineering expertise helps identify areas where waste can be minimized. For instance, designing modular components reduces material wastage during production, while efficient equipment ensures fewer resources are consumed.

Renewable Energy Integration

Renewable energy sources, such as solar or wind power, are being integrated into supply chain operations. Mechanical engineers develop systems that utilize these resources, such as solar-powered conveyor belts or wind-assisted transport vehicles.

Challenges and Future Trends in Mechanical Engineering for Supply Chains

While mechanical engineering has significantly advanced supply chain processes, challenges remain. These include high initial costs of advanced machinery, skill gaps in workforce training, and adapting to rapidly evolving technologies.

However, future trends show promise:

-

Artificial Intelligence and Machine Learning

Mechanical engineering will increasingly integrate AI for predictive maintenance and process optimization, enhancing supply chain resilience. -

3D Printing

On-demand manufacturing using 3D printing technology can revolutionize supply chains by reducing lead times and inventory costs. -

Digital Twins

The creation of virtual replicas of physical assets enables real-time monitoring and simulation, ensuring better decision-making across the supply chain.

Conclusion

Mechanical engineering is a driving force behind the success of modern supply chains. Its influence spans from product design and manufacturing to logistics and sustainability. By integrating advanced technologies, mechanical engineers continue to address challenges, optimize processes, and contribute to a greener future. As industries evolve, the partnership between mechanical engineering and supply chain management will remain critical in meeting global demands efficiently and sustainably.

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Παιχνίδια

- Gardening

- Health

- Κεντρική Σελίδα

- Literature

- Music

- Networking

- άλλο

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness