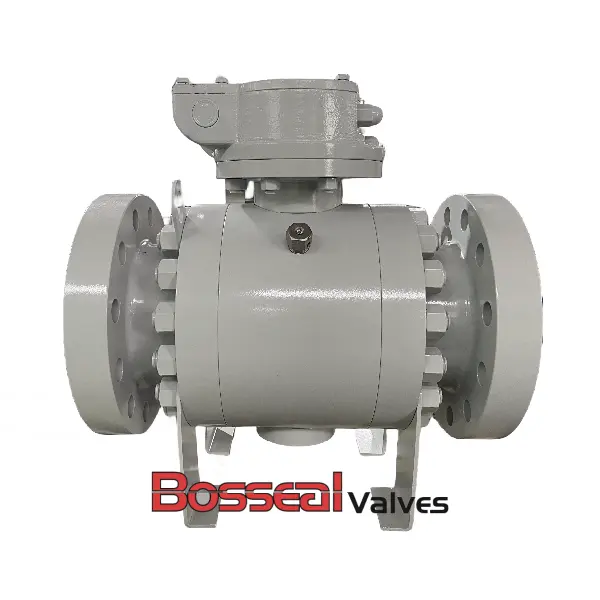

This District Heating Floating Ball Valve, compliant with DIN EN 10217-2 standards, features ST 37.8 construction and is designed for DN15 (1/2 inch) applications with a pressure rating of PN40 (Class 300 LB). The valve is fully welded, has a reduced bore for improved flow characteristics, and is lever operated, ensuring reliable performance in district heating systems.

District Heating Fully Welded Ball Valve

Valve description: Fully Welded District Heating Ball Valve, reduced Bore, floating type

Body material: ST 37.8 (DIN EN 10217-2)

Ball material: SS 304

Nominal diameter: DN15, 1/2 Inch

Nominal class: PN40, Class 300 LB

Seat: RPTFE+C

Face to face: MFR

Test and inspection: GB/T

End connection: BW

Mode of operation: Lever

We also produce the following ball valves:

Fully Welded District Heating Ball Valve

Heating District Welded Ball Valve

Hot Water Fully Welded Ball Valve

This fully welded ball valve is typically constructed from steel pipe or plate, and sometimes from forged steel. It is specifically designed for district heating systems and is widely used in heating plants. Available sizes range from DN15 to DN1400, with pressure ratings from PN10 to PN40. The valve can be configured with reduced bore or full bore options, and features either a floating ball or trunnion-mounted construction.

SIZE RANGE AND PRESSURE CLASS

Size Range: 2-56 Inch (DN50-DN1400)

Pressure Range: Class 150 LB - 2500LB (PN16-PN420)

DESIGN STANDARDS

Design / Manufacture: MFG, API 6D, ASME B16.34, DIN 3357, EN 13709, GB/T 12237, BS 5351

Face to Face Length (Dimension): MFG, API 6D, ASME B16.10, EN 558-1, DIN 3202, JIS B 2002

Flanged Dimension: ASME B16.5, EN 1092-1, BS 4504, DIN 2501

Flanged to ASME B16.5 (2 Inch-24 Inch) and ASME B16.47 Series A / B (26 Inch and above) Clamp / Hub ends on request.

Butt Welding Ends: ASME B16.25, EN 12982, GB/T 12224

Testing: API 598, API 6D, EN 12266-1, EN 1074-1, ISO 5208

China JSC Valve Manufacturer Group Co., Ltd.(

https://www.jscvalve.com/), Started in 2000 as a private limited company , has been a pioneer in China within the valve industry. China JSC Valve Manufacturer Group Co., Ltd. was co-founded by a renowned Engineer with 50 years of experience in the steel and heavy engineering industries, dedicating to supply high quality steel valves to customers all over the world. Our company covers an expansive area of 21,000 square meters and seamlessly integrated design, production, examination, sales, and service to offer comprehensive solutions within the valve industry.

This District Heating Floating Ball Valve, compliant with DIN EN 10217-2 standards, features ST 37.8 construction and is designed for DN15 (1/2 inch) applications with a pressure rating of PN40 (Class 300 LB). The valve is fully welded, has a reduced bore for improved flow characteristics, and is lever operated, ensuring reliable performance in district heating systems.

District Heating Fully Welded Ball Valve

Valve description: Fully Welded District Heating Ball Valve, reduced Bore, floating type

Body material: ST 37.8 (DIN EN 10217-2)

Ball material: SS 304

Nominal diameter: DN15, 1/2 Inch

Nominal class: PN40, Class 300 LB

Seat: RPTFE+C

Face to face: MFR

Test and inspection: GB/T

End connection: BW

Mode of operation: Lever

We also produce the following ball valves:

Fully Welded District Heating Ball Valve

Heating District Welded Ball Valve

Hot Water Fully Welded Ball Valve

This fully welded ball valve is typically constructed from steel pipe or plate, and sometimes from forged steel. It is specifically designed for district heating systems and is widely used in heating plants. Available sizes range from DN15 to DN1400, with pressure ratings from PN10 to PN40. The valve can be configured with reduced bore or full bore options, and features either a floating ball or trunnion-mounted construction.

SIZE RANGE AND PRESSURE CLASS

Size Range: 2-56 Inch (DN50-DN1400)

Pressure Range: Class 150 LB - 2500LB (PN16-PN420)

DESIGN STANDARDS

Design / Manufacture: MFG, API 6D, ASME B16.34, DIN 3357, EN 13709, GB/T 12237, BS 5351

Face to Face Length (Dimension): MFG, API 6D, ASME B16.10, EN 558-1, DIN 3202, JIS B 2002

Flanged Dimension: ASME B16.5, EN 1092-1, BS 4504, DIN 2501

Flanged to ASME B16.5 (2 Inch-24 Inch) and ASME B16.47 Series A / B (26 Inch and above) Clamp / Hub ends on request.

Butt Welding Ends: ASME B16.25, EN 12982, GB/T 12224

Testing: API 598, API 6D, EN 12266-1, EN 1074-1, ISO 5208

China JSC Valve Manufacturer Group Co., Ltd.(https://www.jscvalve.com/), Started in 2000 as a private limited company , has been a pioneer in China within the valve industry. China JSC Valve Manufacturer Group Co., Ltd. was co-founded by a renowned Engineer with 50 years of experience in the steel and heavy engineering industries, dedicating to supply high quality steel valves to customers all over the world. Our company covers an expansive area of 21,000 square meters and seamlessly integrated design, production, examination, sales, and service to offer comprehensive solutions within the valve industry.