What to Expect from Professional CNC Machining Services

CNC (Computer Numerical Control) machining services have revolutionized the manufacturing world, allowing for high-precision parts, reduced human error, and a vast array of materials to be worked with. Professional CNC machining services are essential for industries ranging from aerospace to automotive, medical device manufacturing, and more. This article explores what you can expect when opting for professional CNC machining services, from the initial consultation to the final product delivery.

Initial Consultation and Design Considerations

The process of working with professional CNC machining services starts with a consultation, where you’ll discuss your project’s requirements. During this phase, the service provider will review your design files, often in CAD (Computer-Aided Design) format, to assess the complexity, dimensions, and tolerances of the part or component. The consultation ensures that the CNC machining service can accommodate your project’s specific needs. Expect to have in-depth discussions about your design’s feasibility, material choices, and any adjustments that might be required to optimize the machining process.

The professionals will also offer valuable input during this stage, suggesting modifications that could improve the functionality or manufacturability of your design. CNC machining services often involve collaboration, where engineers and designers work together to ensure that the end product meets the highest standards. This consultation phase is essential for setting realistic expectations regarding timelines, costs, and the overall production process. The clarity gained here helps minimize mistakes and delays down the line.

Material Selection and Precision Machining Capabilities

Once the design is finalized, material selection is a critical aspect of professional CNC machining services. CNC machining can accommodate a wide variety of materials, including metals (aluminum, steel, titanium), plastics (ABS, PEEK, polycarbonate), and composite materials. The choice of material depends on factors such as the intended use of the part, strength requirements, and environmental conditions the part will be exposed to.

One of the significant benefits of professional CNC machining services is their ability to work with these materials to achieve highly precise tolerances. The level of precision offered by CNC machines is remarkable, often within a fraction of a millimeter. Whether it’s a simple part or a complex design with intricate geometries, CNC machining services are equipped to create parts with consistent precision across large production runs. Expect a level of craftsmanship where the precision and quality of each part are guaranteed, ensuring that your product will meet industry standards and perform reliably.

Advanced Technology and Machining Techniques

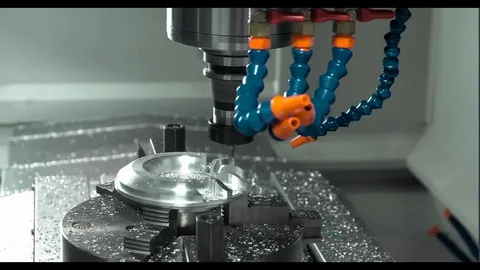

Professional CNC machining services use advanced machinery that can handle a variety of cutting, milling, drilling, and turning operations. Modern CNC machines are equipped with sophisticated software and automation systems, which allow for intricate control over tool paths, speeds, and feed rates. This cutting-edge technology ensures that even the most complex components can be manufactured with accuracy and consistency.

Additionally, CNC machining services employ a range of techniques, such as multi-axis machining, which allows for more complex parts to be produced in fewer steps. Multi-axis machines can move tools along multiple axes simultaneously, enabling the machining of parts with intricate geometries and features that would be difficult or impossible to achieve with traditional methods. As such, when you choose professional CNC machining services, you can expect access to the latest technology and machining techniques that provide exceptional precision and efficiency in manufacturing your components.

Prototyping and Testing

Prototyping is an essential phase in the CNC machining process, where initial samples of the parts are produced to test their fit, form, and functionality. A professional CNC machining service will often offer prototyping as part of the overall service, ensuring that any issues can be identified early on. Prototypes help verify that the design meets your expectations before moving on to full-scale production, saving time and reducing the risk of costly mistakes in the manufacturing process.

Testing of the prototype is typically conducted to ensure that the part performs according to specifications. This could include physical testing, such as stress testing or measuring tolerances, and performance testing in real-world conditions. If any issues arise during the testing phase, the CNC machining service will work with you to refine the design and address any problems before proceeding to mass production. This commitment to prototyping and testing ensures that the final product meets high standards of quality and functionality, giving you confidence in the result.

Final Production and Delivery

Once the prototypes are approved and any necessary adjustments have been made, the final production phase begins. Professional CNC machining services will produce the parts according to the finalized design specifications, ensuring that each piece is consistent and meets the required tolerances. This phase often involves running multiple components at once, which maximizes efficiency and reduces costs for large production runs.

Upon completion, the parts are thoroughly inspected, and if necessary, they undergo secondary processes like coating, assembly, or packaging. You can expect timely delivery of the finished product, often with the option for expedited shipping depending on your timeline requirements. The professionalism of CNC machining services ensures that the final product is not only of the highest quality but also delivered on time, allowing you to proceed with your project or product launch without delays.

Conclusion

Professional CNC machining services offer a comprehensive solution for businesses in need of precision parts, high-quality prototypes, and efficient production runs. From the initial consultation and design to material selection, advanced machining techniques, prototyping, and final delivery, working with expert CNC machinists ensures that you get the best possible results. The combination of cutting-edge technology, skilled professionals, and a focus on quality control makes CNC machining an indispensable part of modern manufacturing. Whether you're producing a few prototypes or large quantities of a product, CNC machining services provide the reliability and expertise needed to meet your manufacturing needs.

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Games

- Gardening

- Health

- Home

- Literature

- Music

- Networking

- Other

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness