What is The Purpose Of Medical Coating?

It is reasonably vital that medical pieces of equipment must be corrosion-resistant. This is why medical coatings have become a crucial part of several medical market applications. However, it is already heavily utilized in the medicinal sector, added research is being done as far as medical coatings being utilized in applications for the finger, spine, shoulder, elbow acetabular caps, knee joints, and femoral stems. And it does not even break the surface

There are both thermal spray and cold technologies utilizes these days in medicinal coatings. Thermal spray medicinal coatings are utilized for medicinal equipment and devices demanding dielectric insulation. Such coatings have several aids and advantages.

The Application Of Medical Coatings

The medical coating is vital to support matching the hygienic and health levels of the industry. All medical pieces of equipment should fulfill certain sterility levels to be appropriate for usage in medical settings.

Polymer coating enables the welding of materials to make them capable enough of holding air. Some equipment that needs such ability includes pressure infuser bags, blood pressure cuffs, hyperbaric chambers, inflatable tourniquets, cold/ice casts, and therapy devices.

The medicinal coating also stops liquid diffusion and upholds antimicrobial characteristics for the devices.

Advantages of Medicinal Coatings

The textile coating can advance a material’s properties and can better its performance on basis of the requirement and application of the aimed product. Some of the typical properties that textile coating can improve in a medical device are:

- Fire resistance

- Supports wielding

- Heat stability

- Water-resistant

- Toughness

- Scratch resistance

- Air holding abilities

- Noise reduction abilities

- Antimicrobic characteristics

The medical coating is also vital in the biomedical field to perform transplants better matched to interact with bone tissues. Also, here are some other added advantages of medicinal coating:

- Fast bone development

- solderability

- quick healing

- Improved bond strength

- Less oxide coating

- Interconnected porosity

Hydrophilic Coating

Hydrophilic coating methods make polymeric devices vulnerable to liquids by allowing polymers into covalent bonds by making water-attracting surfaces. The prurience and water-holding properties decrease the force needed to manipulate intravascular medical devices in interventional events.

Silver Medical Coating

Silver has an extended and fascinating history as an antibiotic in human healthcare. It has been advanced for utilization in wound care, bone prostheses, water purification, reconstructive orthopedic surgery, catheters, and surgical appliances. Enhancing biotechnology has allowed the merger of ionizable silver into fabrics for clinical usage to decrease the danger of nosocomial contagions and for personal cleanliness.

Titanium Coating

Titanium (Ti) and its alloys are extensively utilized for medicinal and dental transplant devices— bone fixators, artificial joints, dental implants, spinal fixators, and many others.

Mainly because they display outstanding corrosion resistance and decent hard-tissue compatibility bone formation and bone attachment capability. Osseointegration is the primary device of the interface structure between titanium and bone tissue. This method of osseointegration was instantly spread to dental-materials researchers globally to demonstrate the benefits of titanium as a transplant material than to other metals.

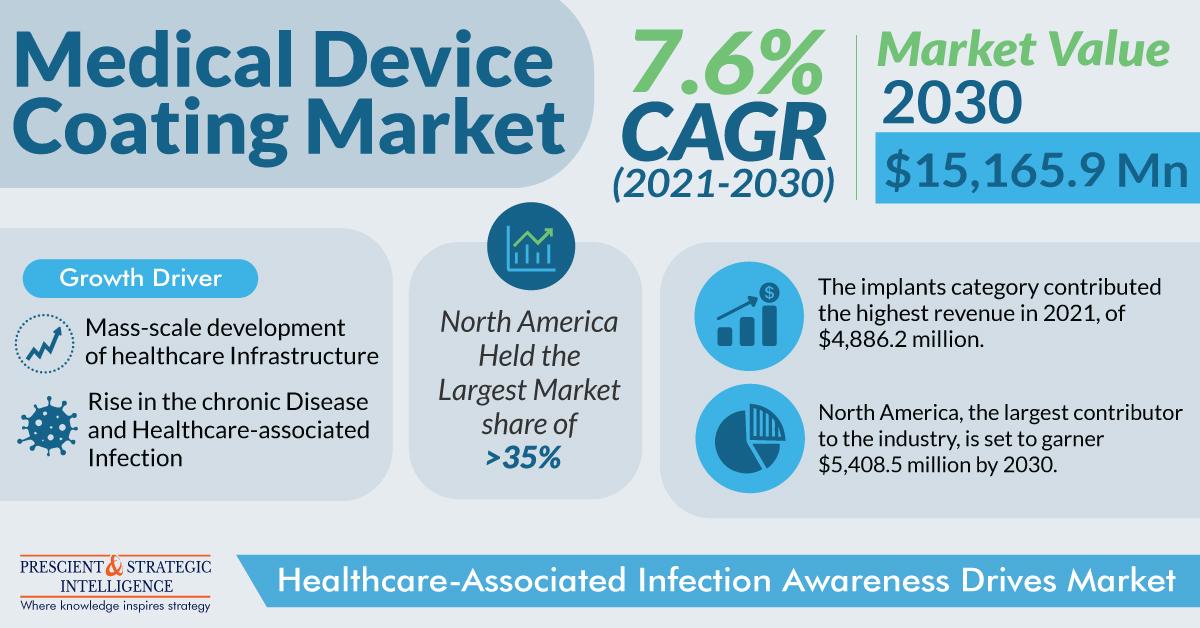

Hence, Medical Device Coating Market is experiencing growth and is projected to reach USD 15,165.9 million by 2030.

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Παιχνίδια

- Gardening

- Health

- Κεντρική Σελίδα

- Literature

- Music

- Networking

- άλλο

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness