How Plastic Moulds Shape Automotive Components

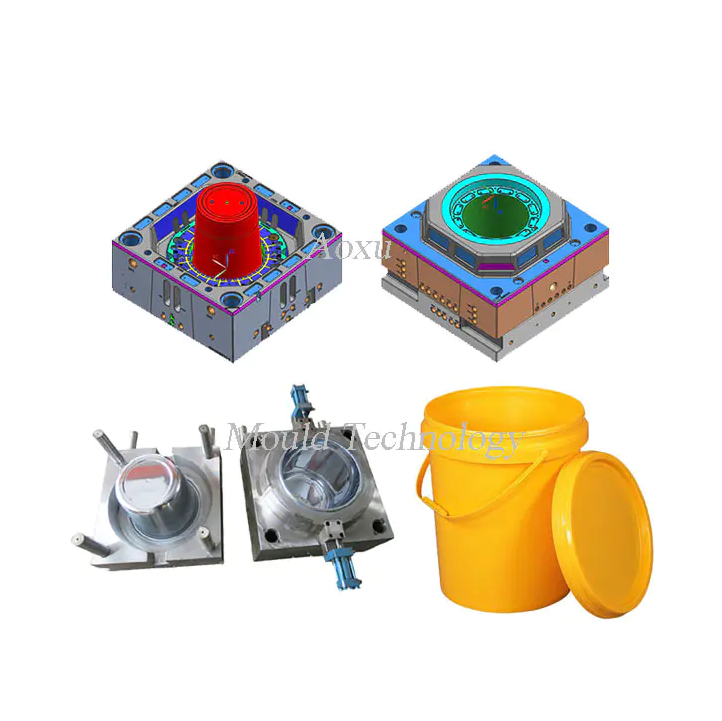

Automotive plastic moulds play a critical role in the production of vehicle components. These moulds are used to shape plastic materials into parts such as dashboards, bumpers, and interior panels, ensuring precise dimensions and consistent quality.

Plastic moulds are highly valued for their ability to produce lightweight and durable components, which contribute to the overall efficiency and performance of vehicles. The flexibility of plastic as a material allows for complex designs and intricate detailing, which are often required in modern automotive parts.

The production process for automotive plastic moulds involves advanced techniques such as injection moulding. This method ensures accurate shaping, minimal waste, and efficient manufacturing cycles, making it an ideal choice for mass production in the automotive industry.

By utilizing automotive plastic moulds, manufacturers can achieve cost-effective production while maintaining high standards of quality and reliability.

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Spiele

- Gardening

- Health

- Startseite

- Literature

- Music

- Networking

- Andere

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness