Temperature Controlled Packaging Market Innovation: Exploring New Solutions for Safe and Sustainable Deliveries

In today’s fast-paced global economy, the demand for temperature-sensitive goods is on the rise. From pharmaceuticals and vaccines to perishable food items and high-end cosmetics, the need for effective temperature-controlled packaging has never been greater. With the growth of e-commerce and global supply chains, maintaining the safety, integrity, and quality of temperature-sensitive products during transport and storage is a critical challenge. As a result, the temperature-controlled packaging market is seeing innovative solutions that cater to these needs while focusing on sustainability and cost-effectiveness.

The Need for Temperature Controlled Packaging

Temperature-controlled packaging is vital for industries where products need to be stored and transported within a specific temperature range to avoid degradation or spoilage. The pharmaceutical industry, for instance, requires precise temperature management for vaccines, biologics, and other temperature-sensitive medications. Similarly, the food and beverage industry faces increasing pressure to ensure products remain fresh throughout the supply chain.

The COVID-19 pandemic amplified the importance of temperature-controlled packaging, especially in the pharmaceutical sector. The global distribution of COVID-19 vaccines required an efficient and reliable cold chain solution to maintain the integrity of the vaccine from manufacturer to end-user. This has highlighted not only the importance of temperature control but also the need for innovative solutions to meet the growing demand for safe deliveries.

Innovations in Temperature Controlled Packaging

-

Smart Packaging Solutions

One of the most significant innovations in the temperature-controlled packaging market is the advent of smart packaging. Smart packaging incorporates sensors, GPS tracking, and real-time data logging to monitor and maintain the required temperature throughout the entire supply chain. These sensors help track temperature fluctuations, alerting stakeholders of any deviations, which could compromise the integrity of the product. Additionally, data logging allows for post-shipment analysis, ensuring that goods are delivered under optimal conditions. The ability to track shipments in real-time offers transparency and peace of mind to both businesses and consumers. -

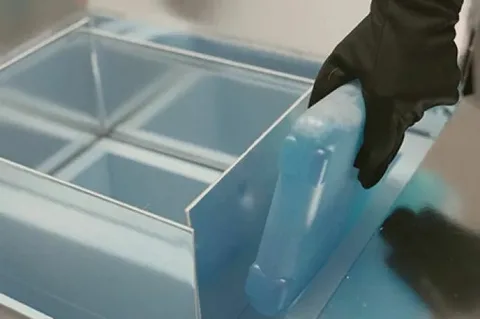

Phase Change Materials (PCMs)

Another innovation that has revolutionized the temperature-controlled packaging market is the use of phase change materials (PCMs). These materials absorb and release heat during their phase transition, effectively stabilizing temperature fluctuations during transit. PCMs can maintain a specific temperature for an extended period, making them ideal for sensitive products like vaccines and biologics. They are also environmentally friendly as many PCMs are made from natural substances, reducing the environmental impact of packaging solutions. -

Sustainable and Eco-friendly Solutions

Sustainability is a growing concern within the packaging industry, and temperature-controlled packaging is no exception. Manufacturers are increasingly turning to eco-friendly materials such as recyclable plastics, biodegradable foams, and renewable raw materials. There is also a significant push towards reducing single-use packaging. Reusable packaging solutions, such as insulated containers that can be returned and reused multiple times, are becoming more popular in the temperature-controlled space.

Companies are also focusing on reducing the carbon footprint of their operations. One way to achieve this is by using more energy-efficient cooling systems, reducing the overall energy consumption of cold chain logistics. With the rise of global awareness about climate change, these sustainable solutions not only cater to customer preferences but also align with regulatory requirements and environmental goals.

-

Insulated Shipping Boxes and Bags

The development of advanced insulated shipping boxes and bags has further driven the innovation in the temperature-controlled packaging market. These packaging solutions are designed to protect temperature-sensitive products from external temperature fluctuations while also reducing the risk of exposure to contamination. The latest models incorporate layers of insulation, air-tight seals, and superior moisture resistance to keep goods safe during transit. -

Active and Passive Temperature Control Systems

Active and passive temperature control systems are other innovations in the market. Active systems, such as refrigerated trucks or air-conditioned containers, regulate the temperature dynamically during transit, ensuring constant temperature control. On the other hand, passive systems, such as insulated packaging with ice packs or gel packs, rely on the natural properties of insulation and temperature retention. Both systems have their advantages, with active systems offering more control but at a higher cost, and passive systems being cost-effective and sustainable.

Challenges and Opportunities Ahead

While the temperature-controlled packaging market has made significant strides in innovation, it still faces several challenges. One of the key hurdles is the need for consistent regulatory standards across regions. Different countries have varying requirements for temperature-controlled packaging, which can complicate global supply chains. Additionally, the cost of advanced packaging solutions can be prohibitive for small businesses, hindering their ability to compete in the global market.

However, these challenges present opportunities for continued innovation. As the demand for temperature-sensitive goods grows, there will be increased investment in research and development to create more cost-effective and sustainable solutions. The rise of the circular economy, with a focus on reducing waste and reusing resources, will likely play a key role in shaping the future of temperature-controlled packaging.

Conclusion

The temperature-controlled packaging market is experiencing rapid innovation to meet the demands of an increasingly globalized and temperature-sensitive world. With advancements in smart packaging, sustainable materials, and more efficient systems, the industry is making great strides in ensuring the safe and reliable delivery of sensitive products. As the market continues to grow, businesses will need to adopt these innovations to stay competitive and meet the evolving needs of their customers.

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Jeux

- Gardening

- Health

- Domicile

- Literature

- Music

- Networking

- Autre

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness