The ultrasonic flowmeter market is experiencing significant growth, driven by a range of technological, economic, and regulatory factors. Ultrasonic flowmeters, which measure fluid flow rates by using high-frequency sound waves, are known for their non-invasive operation, precision, and adaptability across various applications. With industries such as oil and gas, water and wastewater management, chemical processing, and energy increasingly turning to ultrasonic flowmeters for efficient flow measurement, this article explores the primary factors fueling market growth.

1. Demand for Accurate and Non-Invasive Flow Measurement Solutions

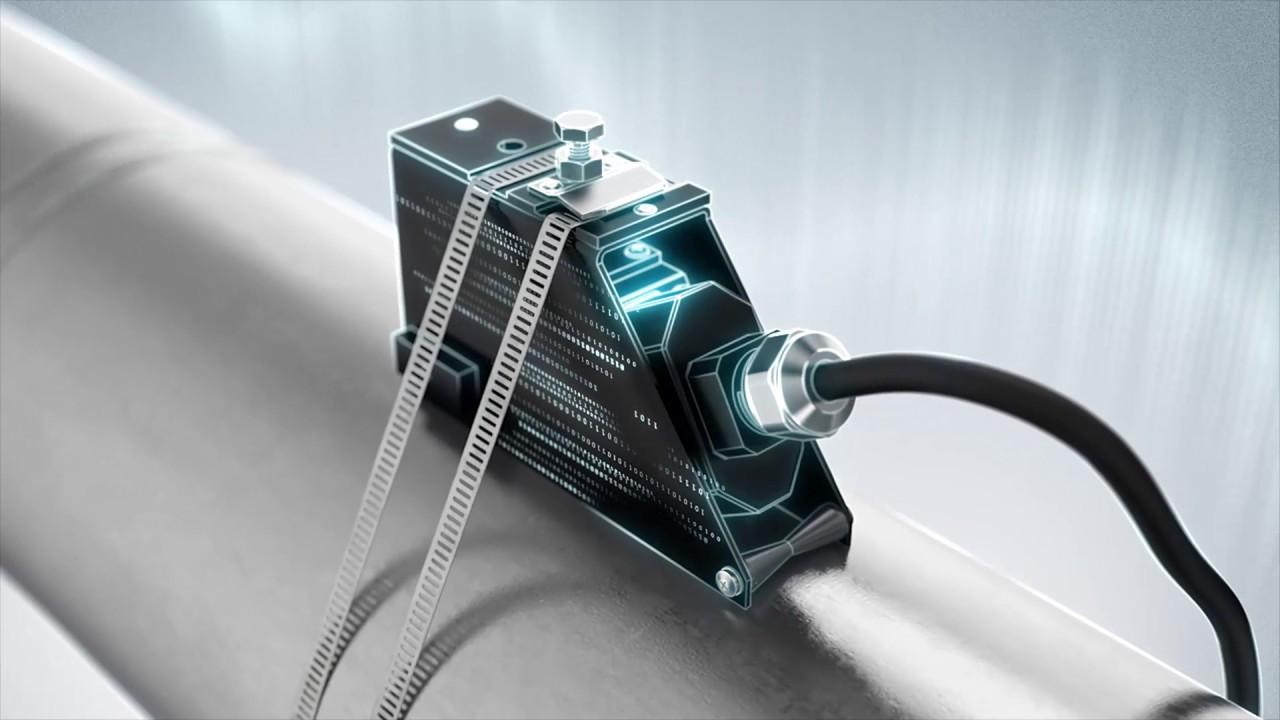

One of the strongest drivers of the ultrasonic flowmeter market is the demand for accurate, non-invasive flow measurement technologies. Unlike traditional flowmeters, which may involve mechanical parts or contact with the fluid, ultrasonic flowmeters measure flow externally, which preserves the integrity of both the device and the fluid. This non-invasive nature minimizes wear and tear, reduces maintenance costs, and is ideal for applications involving hazardous or sensitive fluids.

Industries such as pharmaceuticals, food and beverage, and water treatment are increasingly adopting ultrasonic flowmeters due to their accuracy and reduced risk of contamination. The technology's ability to measure flow without interfering with the fluid flow path is especially valuable in sectors where maintaining purity and preventing cross-contamination are top priorities.

2. Rising Demand in Water and Wastewater Management

The water and wastewater management sector is a significant growth area for ultrasonic flowmeters. With rising concerns over water scarcity, waste, and environmental impact, efficient water management has become a priority globally. Ultrasonic flowmeters play a crucial role in helping municipalities and industries monitor water usage, detect leaks, and ensure regulatory compliance. Their accuracy and ease of installation make ultrasonic flowmeters a preferred choice for water flow applications.

Governments and organizations worldwide are investing in advanced water management infrastructure, which further drives demand for ultrasonic flowmeters. These investments are particularly strong in regions where water scarcity is a pressing issue, as ultrasonic flowmeters help optimize water usage and reduce waste in both urban and industrial settings.

3. Expanding Applications in the Oil and Gas Industry

The oil and gas industry is another major sector contributing to the growth of the ultrasonic flowmeter market. In applications such as pipeline monitoring, gas metering, and custody transfer, ultrasonic flowmeters provide the high levels of accuracy and reliability needed for precise flow measurement. These devices are particularly valued for their durability in high-pressure environments and ability to measure flow in both liquid and gas pipelines, making them versatile tools in this sector.

The global demand for energy continues to grow, driving oil and gas companies to invest in advanced technologies to improve operational efficiency and safety. Ultrasonic flowmeters, with their ability to handle a wide range of flow rates and withstand harsh environmental conditions, are increasingly seen as essential tools in meeting these demands.

4. Advances in Digital Technology and Industrial IoT Integration

The integration of digital technology and the Industrial Internet of Things (IIoT) is revolutionizing the flowmeter industry, and ultrasonic flowmeters are no exception. Modern ultrasonic flowmeters often come with smart capabilities, including real-time data logging, remote monitoring, and predictive analytics. These features enable industries to monitor flow data continuously, detect issues early, and optimize operational efficiency.

IIoT integration allows ultrasonic flowmeters to connect with other systems, offering centralized control and analysis of flow data. This connectivity provides a holistic view of the entire process, which is essential for industries that prioritize precision, efficiency, and sustainability. The ability to perform predictive maintenance based on real-time data also helps companies prevent costly downtime and improve productivity.

5. Growing Focus on Environmental Compliance and Sustainability

As industries and governments increasingly prioritize environmental responsibility, ultrasonic flowmeters are becoming valuable tools for supporting sustainability goals. Precise flow measurement allows for better resource management, reduced waste, and more efficient energy use, all of which contribute to minimizing environmental impact. In industries where regulatory compliance is critical, such as water management, oil and gas, and chemical processing, ultrasonic flowmeters help ensure that operations meet environmental standards.

Furthermore, ultrasonic flowmeters can measure both low and high flow rates, making them adaptable to varying conditions and minimizing the need for multiple devices. This adaptability not only reduces costs but also contributes to sustainable practices by decreasing the need for replacement parts and energy-consuming maintenance routines.

6. Increased Adoption of Portable Ultrasonic Flowmeters

Another trend driving growth in the ultrasonic flowmeter market is the rising demand for portable flowmeters. Portable ultrasonic flowmeters offer flexibility for applications where permanent installation may not be practical or necessary, such as on-site inspections, maintenance checks, or temporary setups. These devices are easy to transport and set up, making them ideal for fieldwork and troubleshooting, where reliable flow data is needed quickly and efficiently.

The increasing adoption of portable flowmeters aligns with the broader shift toward versatile, on-demand solutions in industrial measurement. Portable ultrasonic flowmeters allow companies to conduct tests and measurements in a variety of locations and conditions without compromising accuracy, further supporting the expansion of the market.

Conclusion

The ultrasonic flowmeter market is experiencing robust growth due to a combination of technological advancements, rising demand across diverse sectors, and the push toward sustainable and efficient operations. Key growth factors such as the need for accurate, non-invasive flow measurement, demand in water and wastewater management, increasing adoption in oil and gas, and the integration of IIoT capabilities are transforming the industry.

As these factors continue to evolve, ultrasonic flowmeters are positioned to become even more integral in industries that rely on precise flow measurement and data-driven decision-making. Moving forward, innovations that enhance device accuracy, reduce costs, and expand application versatility will further drive the market’s growth, solidifying the role of ultrasonic flowmeters as essential tools for a variety of modern industrial processes