Rotary Pumps Market: Spotlight on Leading Manufacturers

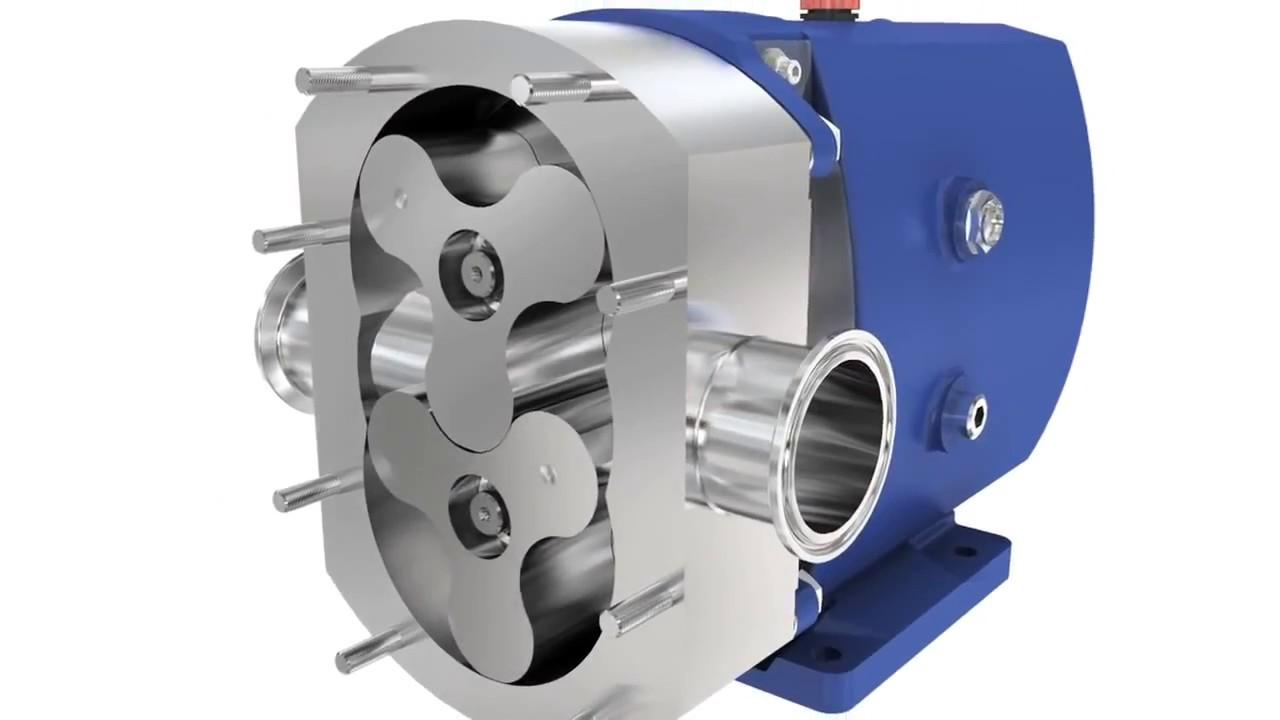

The rotary pumps market is poised for significant evolution in the coming years, driven by various factors that shape industrial needs and technological advancements. Rotary pumps, known for their efficiency in fluid transfer, are critical in numerous applications, including oil and gas, chemicals, food and beverage, and pharmaceuticals. As industries increasingly prioritize efficiency, sustainability, and automation, the market for rotary pumps is expected to expand considerably.

Technological Advancements

The landscape of rotary pumps is being reshaped by ongoing technological innovations. The integration of smart technologies, such as IoT and AI, is enhancing the capabilities of these pumps, allowing for real-time monitoring and predictive maintenance. This shift not only improves operational efficiency but also minimizes downtime and reduces operational costs. Manufacturers are investing in developing advanced materials that can withstand harsh conditions and extend the life of rotary pumps, making them more reliable and efficient in their respective applications.

The rise of electric and variable frequency drive (VFD) technology is transforming how rotary pumps operate. By enabling precise control over flow rates and pressures, these technologies allow for greater flexibility in various processes, catering to the dynamic needs of modern industries. This adaptability is a crucial factor in meeting the growing demand for customized solutions across diverse sectors.

Sustainability and Environmental Considerations

As global emphasis on sustainability intensifies, industries are under pressure to adopt environmentally friendly practices. Rotary pumps play a vital role in this transition, particularly in sectors such as wastewater management and renewable energy. The push for greener technologies is leading to the development of pumps that consume less energy and use fewer resources during operation.

Manufacturers are also exploring designs that minimize leakage and emissions, further aligning with global sustainability goals. The implementation of eco-friendly materials and manufacturing processes is expected to become a standard practice in the rotary pump industry, appealing to environmentally conscious consumers and regulators alike.

Market Segmentation and Regional Dynamics

The rotary pumps market is characterized by diverse applications, each with unique demands. In the oil and gas sector, for instance, the need for robust and efficient pumping solutions continues to grow as exploration and production activities expand. Similarly, the food and beverage industry requires pumps that ensure hygiene and product integrity, prompting innovations in materials and designs.

Geographically, emerging markets in Asia-Pacific, Latin America, and Africa present substantial growth opportunities. Rapid industrialization and urbanization in these regions are driving demand for rotary pumps in various applications, including construction and manufacturing. As economies develop, the need for efficient fluid handling solutions will become increasingly critical, positioning rotary pumps as essential components of industrial infrastructure.

Challenges and Competitive Landscape

Despite the promising outlook, the rotary pumps market faces challenges that could impact growth. Price fluctuations in raw materials can affect production costs, while regulatory compliance in various industries may impose additional burdens on manufacturers. Additionally, the competitive landscape is becoming increasingly crowded, with numerous players vying for market share. Companies must differentiate themselves through innovation, quality, and customer service to maintain a competitive edge.

Strategic partnerships and collaborations are emerging as effective strategies for navigating these challenges. By aligning with technology providers or industry leaders, rotary pump manufacturers can enhance their product offerings and expand their market reach.

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Games

- Gardening

- Health

- Home

- Literature

- Music

- Networking

- Other

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness